Rail vehicle and vehicle body structure thereof

A technology of rail vehicle and car body structure, applied in railway car body, railway car body parts, transportation and packaging, etc., can solve the problems of complex propagation mode, high noise source, difficult control, etc. The effect of high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

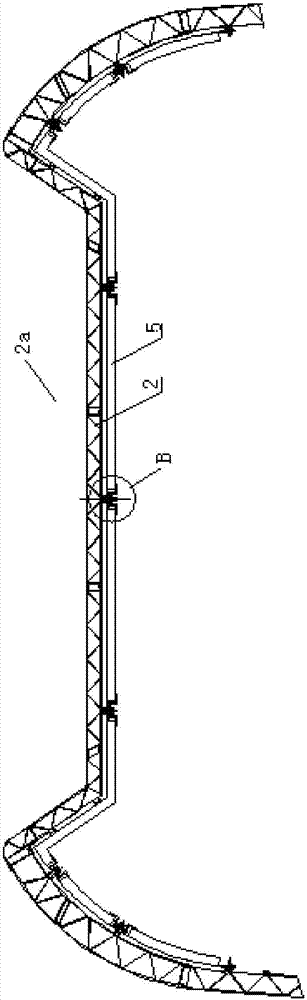

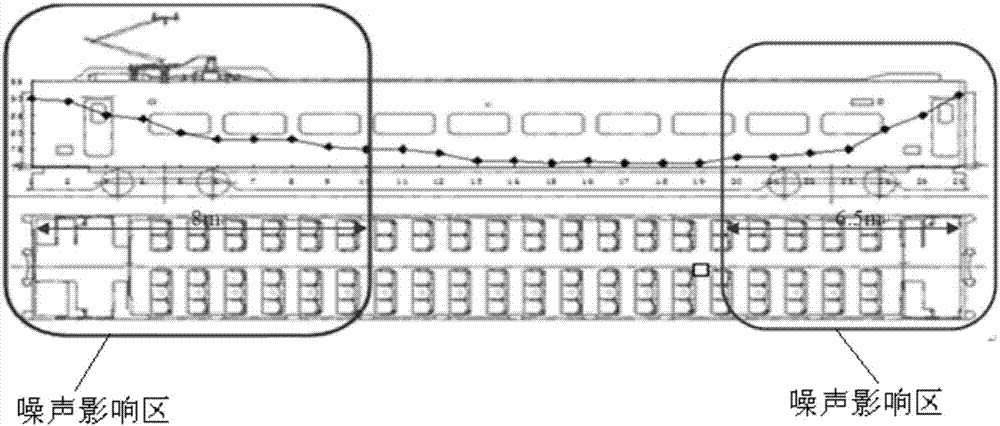

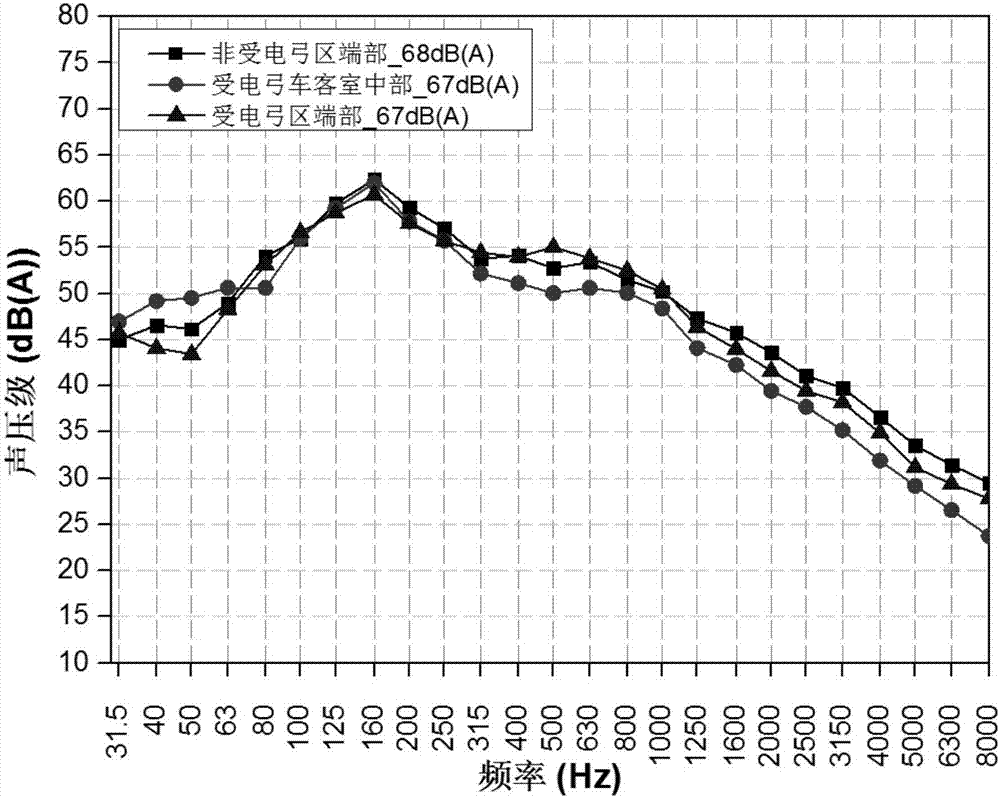

[0029] This paper conducts an in-depth study on the impact of the noise generated by the pantograph described in the background art on the interior of the guest room. The research found that the noise and vibration sources in the pantograph area can be divided into vibration excitation and noise excitation, both of which are very large, and should be carried out simultaneously from the aspects of sound insulation and vibration reduction. The installation of sound-absorbing and vibration-damping materials between the car body and the interior trim has a certain effect on reducing the noise inside the car, but the noise in the pantograph area is still higher than that in other areas of the passenger compartment.

[0030] The noise in the passenger room is related to the thickness of the sound-absorbing and vibration-damping material. The thicker the sound-absorbing and vibration-damping material, the better the sound-absorbing effect. However, the thickness of the sound-absorbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com