Automatic assembly system of injection syringes

A technology of automatic assembly and syringe, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency and unsanitary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

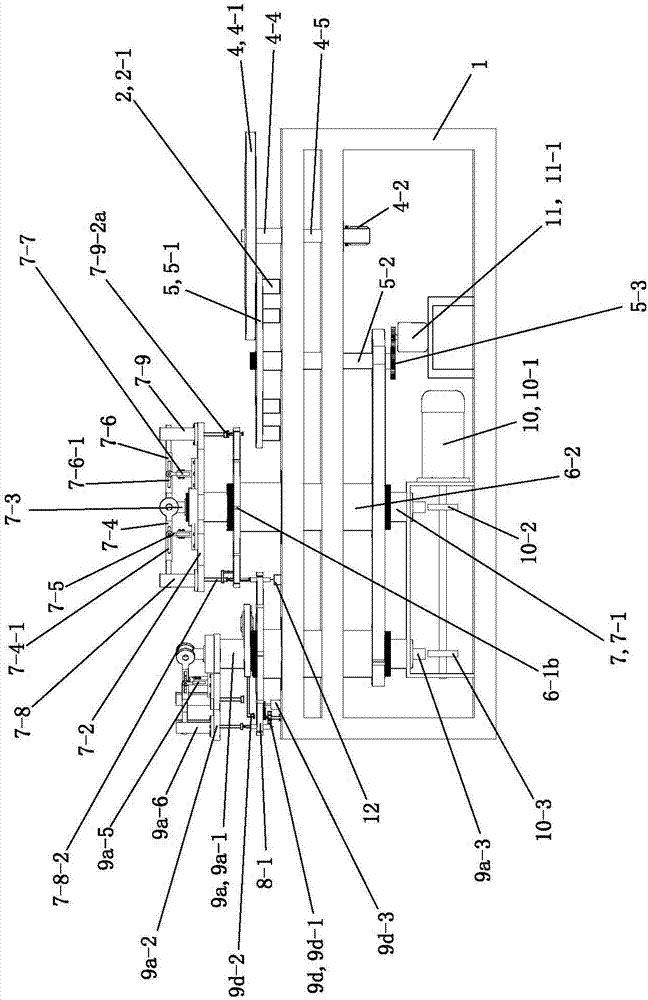

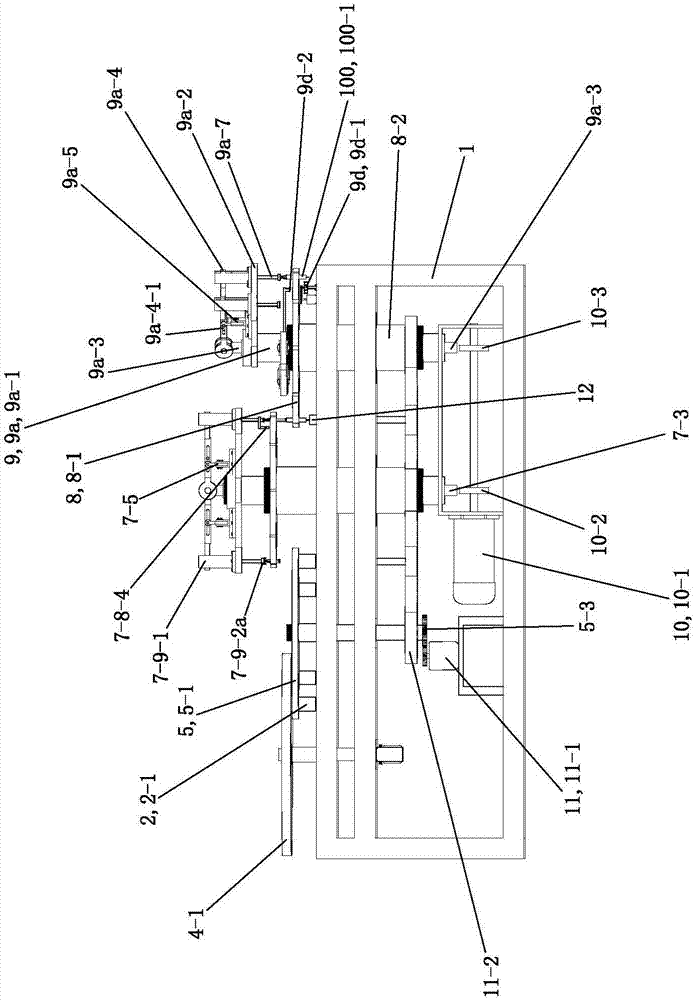

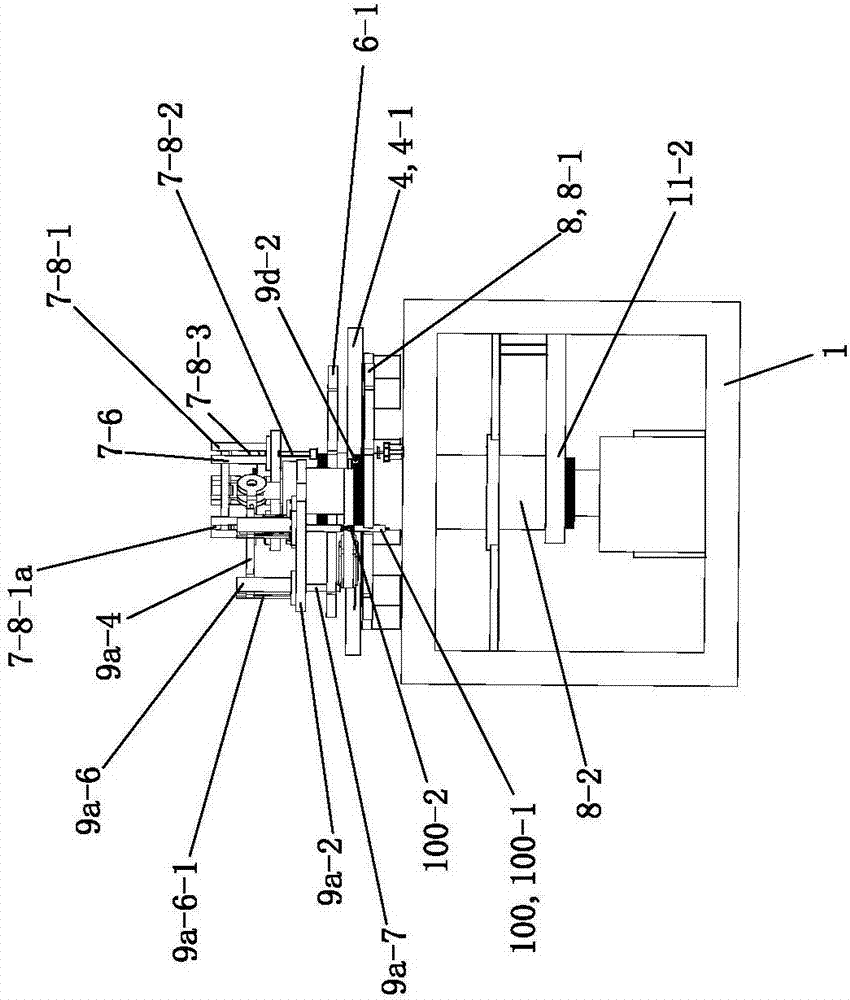

[0105] See Figure 1 to Figure 12 The automatic assembly system of the syringe of the present invention includes a frame 1, an O-ring assembly assembly 2, a clamping assembly 3, an O-ring feeding assembly 4, an O-ring transfer assembly 5, a piston transfer assembly 6, a piston assembly assembly 7, A syringe transfer assembly 8 , a detection assembly assembly 9 , a lifting drive assembly 10 , a synchronous drive assembly 11 and a syringe plug 12 .

[0106] See Figure 7 to Figure 10 , The O-ring assembly assembly 2 includes a first housing 2-1, an upper cover plate 2-2, a lower cover plate 2-3, a positioning mandrel 2-4, an O-ring expansion claw 2-5, and a positioning support ring 2- 6. Circlip, O-shaped spring and elastic positioning film.

[0107] The first shell 2-1 is in the shape of a cylindrical shell. The upper cover plate 2-2 is screwed and fixed on the upper part of the first shell 2-1. The middle part of the upper cover plate 2-2 is provided with a first central t...

Embodiment 2)

[0158] The rest of this embodiment is the same as that of Embodiment 1, the difference is that: the finished product discharging device 9d is a shift fork. The shift fork is fixedly arranged on the frame, and the two ends of the shift fork are respectively located on the upper and lower sides of the third rotating connecting plate 8-1. When the corresponding clamping assembly 3 carries the finished syringe through the finished product discharge device 9d, the syringe 100 is blocked by the finished product discharging device 9d and falls away from the clamping assembly 3 and falls into the corresponding finished product storage device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com