Contact type printed circuit board (PCB) cleaning device

A PCB board and cleaning device technology, applied in the direction of cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as difficult and small holes, uneven cleaning of water jets, deformation of PCB boards, etc., and achieve reduction Friction, cleaning without dead zone, easy to move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

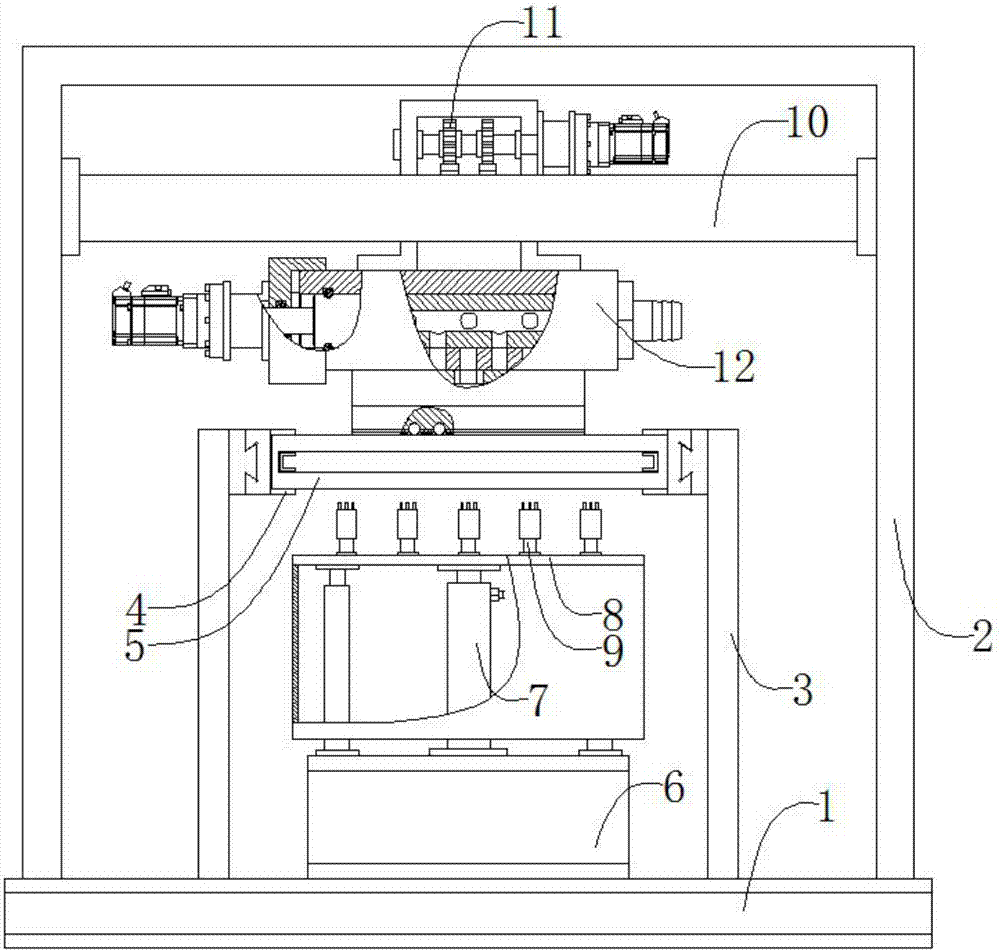

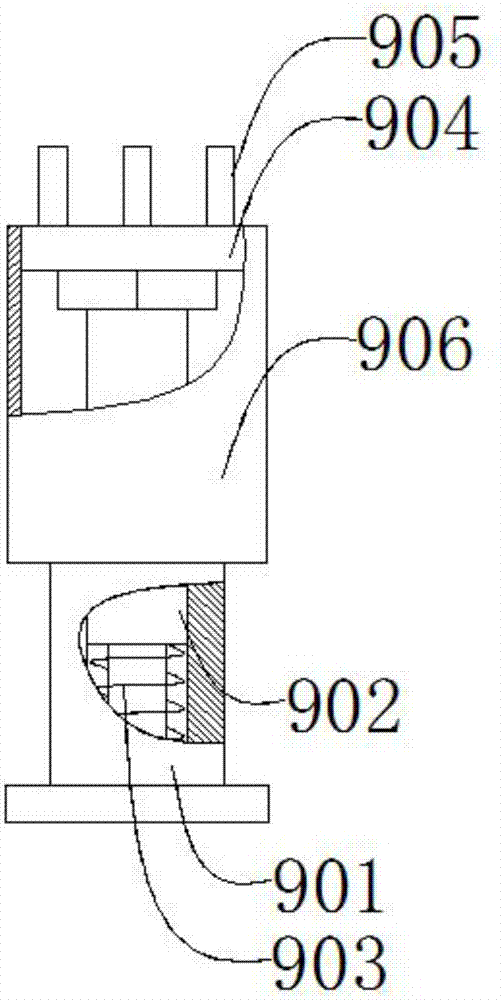

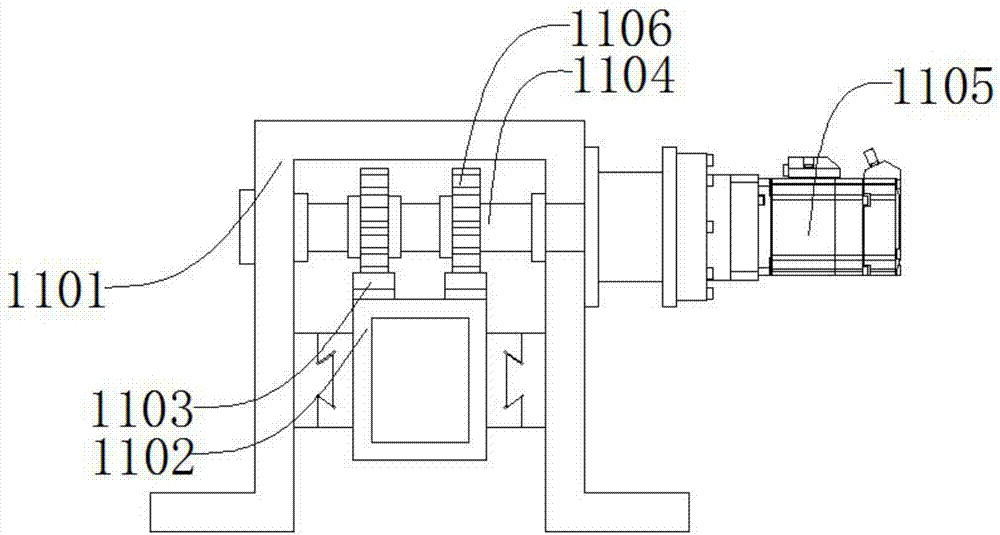

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a contact-type PCB board cleaning device includes a base 1, a door frame 2, a vertical frame 3 arranged symmetrically along the base 1 with a number of 2 pieces, an insert strip 4, a connecting plate 5, a booster pad 6, and a cylinder 7 , supporting plate 8, elastic supporting mechanism 9, beam 10, feeding mechanism 11, liquid spraying mechanism 12, the number of which is evenly arranged along the supporting plate 8 is no less than 2 pieces, and the door frame 2 is located at the upper end of the base 1, so The door frame 2 is threadedly connected with the base 1, the vertical frame 3 is located at the upper end of the base 1, the vertical frame 3 is threaded with the base 1, the insert strip 3 is located at the upper end of the vertical frame 3, and the inserted frame 3 is located at the upper end of the base 1. The bar 4 is threadedly connected with the vertical frame 3, the connecting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com