Convenient-to-remove electrode connection structure for electric heating floor

A technology of connecting structure and electric heating floor, applied in ohmic resistance electrodes, electric heating systems, ohmic resistance heating parts, etc., can solve the problems of no focus point of the movable magnet, easy desoldering when removing wires, etc. The effect of desoldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

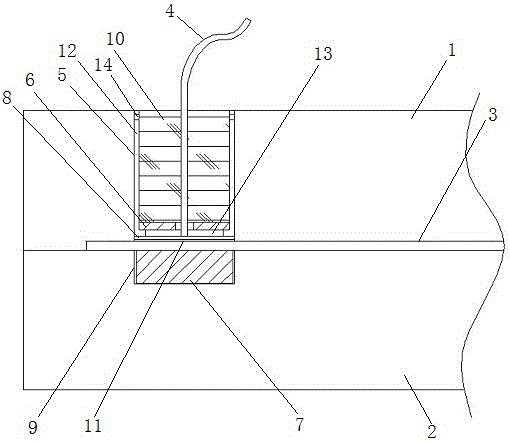

[0017] Such as figure 1 The electrode connection structure of an electric heating floor that is easy to disassemble is shown, including a base plate 1, a panel 2, and a conductive heating layer 3 arranged between the base plate 1 and the panel 2. The electrodes 11 of the conductive heating layer 3 are welded with The wire 4 of the conductive sheet 8 is connected to the power supply, the bottom plate 1 and the panel 2 on both sides of the electrode 11 are respectively provided with a hole 5 and a groove 9, and a B magnet 7 is fixed in the groove 9, which is located on the wire 4 in the hole 5 Covered with A magnet 6 and an insulating plug 10 made of insulating sponge, it also includes a cylindrical magnet seat 12 connected to the hole 5. The closed end of the magnet seat 12 is provided with a wire through hole 13, and the open side wall is symmetrically provided with The pry hole 14, the outer wall of the closed end is attached to the conductive sheet 8, the inner wall is attac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com