Prefabricated pump station unit and water distribution unit

A pumping station and water distribution technology, applied in waterway systems, water supply devices, drainage structures, etc., can solve problems such as uneven flow patterns and complex technical solutions, and achieve the effects of reducing construction periods, facilitating transportation, and eliminating energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

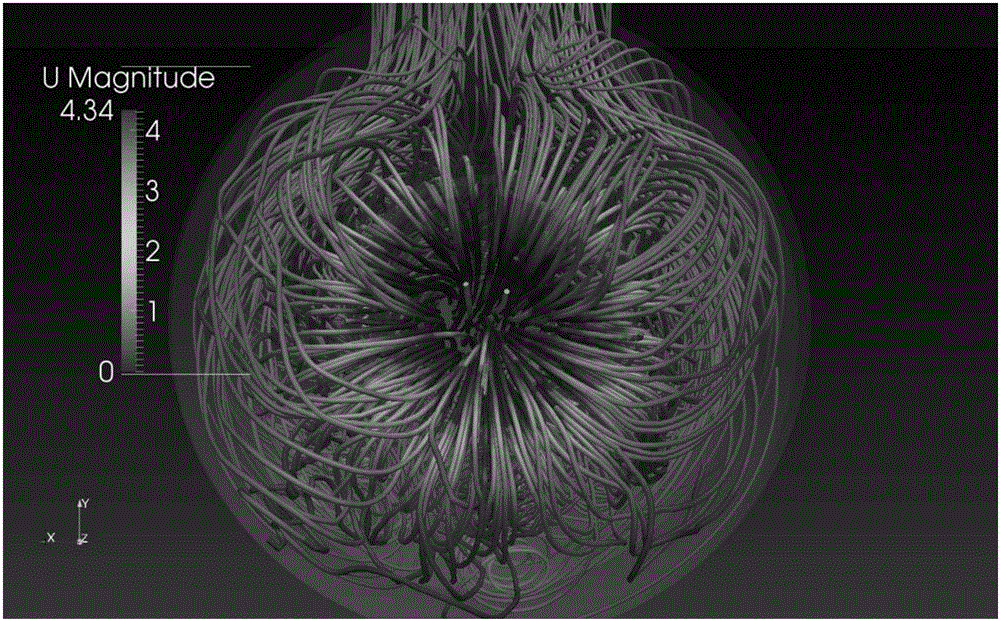

[0082] see Figure 7 , Figure 7 It is a three-dimensional structural schematic diagram of the second embodiment of the prefabricated pumping station unit of the present invention. see Figure 7 , the second embodiment of the prefabricated pump station unit of the present invention is the same as Figure 1 to Figure 4 The main differences of the first embodiment shown are:

[0083] The inner cylinder 12 is in the shape of a cone as a whole, and has a large end with a larger diameter and a small end with a smaller diameter, wherein the end with a larger diameter is located inside the outer cylinder 11 . When the fluid flows downward along the inner wall of the cone-shaped inner cylinder 12, the flow state of the fluid will be further homogenized.

[0084] Other structures of the second embodiment of the prefabricated pumping station unit are basically the same as those of the first embodiment, and will not be repeated here.

[0085] Embodiment 3 of prefabricated pumping st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com