Trimable Impeller Device and System

An impeller, blade technology, applied in pump devices, components of pumping devices for elastic fluids, mixers with rotary stirring devices, etc., can solve problems such as lack of cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

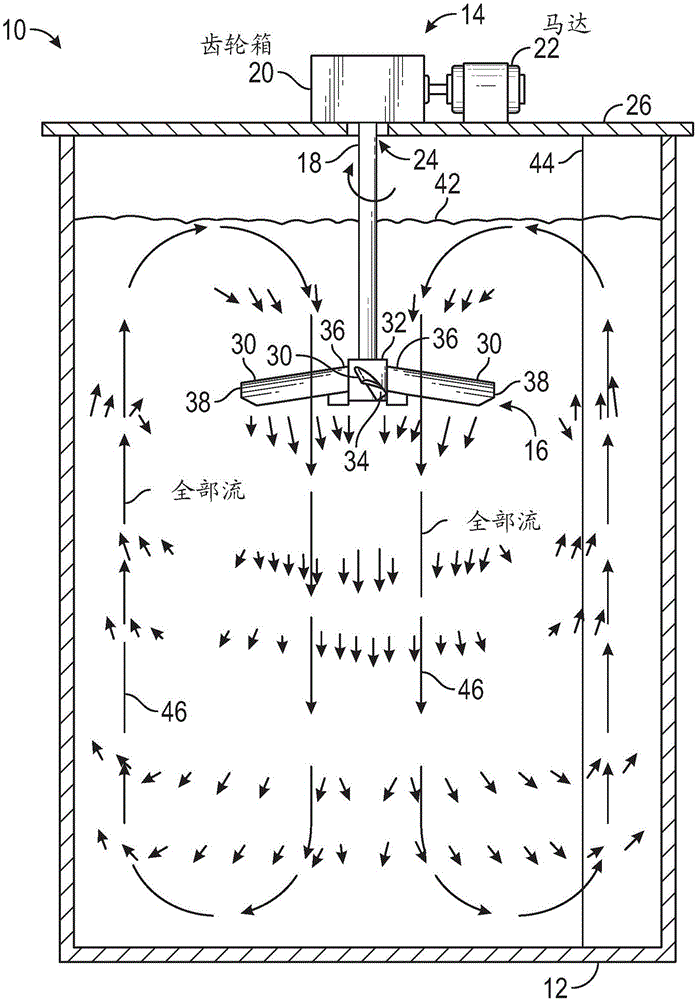

[0028] The various aspects of the impeller described herein are suitable for use in mixing devices, particularly devices for the mixing of liquids, liquid suspensions of solids, and gases contained in containers. More specifically, aspects of the impellers described herein are suitable for use in mixing equipment for chemical processing, possibly in mixers, aerators, and other mixing operations for solids suspensions and emulsifiers.

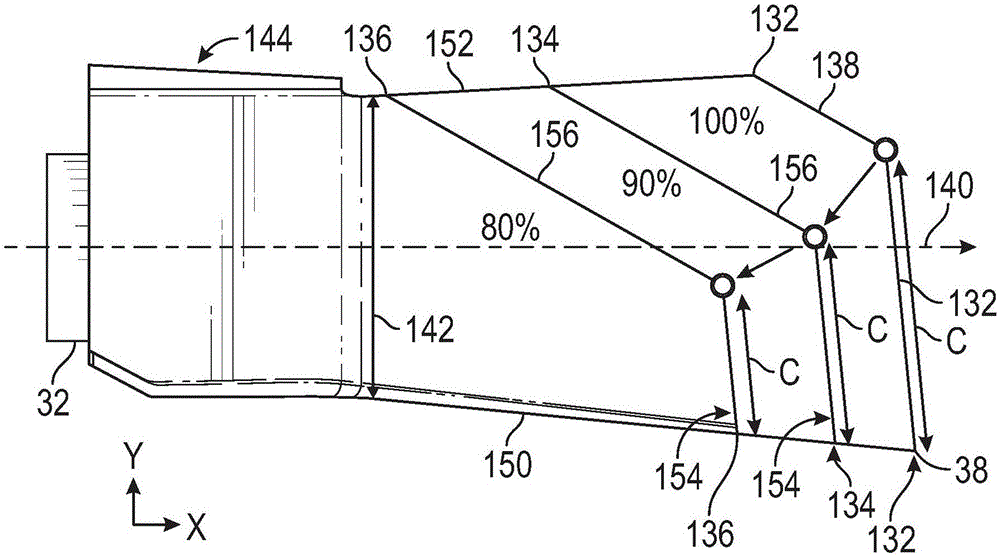

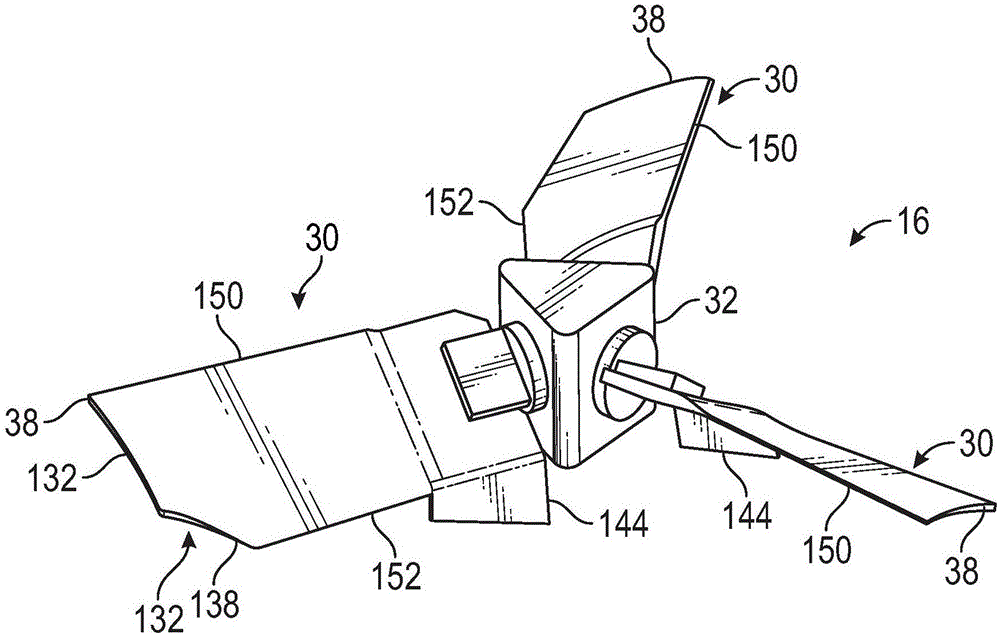

[0029] Embodiments will now be described with reference to the drawings in which like reference numerals refer to like parts throughout. figure 1 is a cutaway perspective view of the impeller system 10 for use with a container 12 suitable for use in the embodiments. Such as figure 1 As shown, the impeller system 10 includes an impeller assembly 14 . The impeller assembly 14 includes an impeller 16 and a shaft 18 . The impeller system 10 further includes a gearbox 20 and a motor 22 . Container 12 includes any suitable container or vessel, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com