Underground perforation test tool string optimization method based on packer stress analysis

A force analysis and optimization method technology, applied in design optimization/simulation, instrumentation, special data processing applications, etc., can solve problems such as large damage and failure of the pipe string, less dynamic behavior, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0092] An optimization method for downhole perforation testing tool string based on packer force analysis, which includes the following steps:

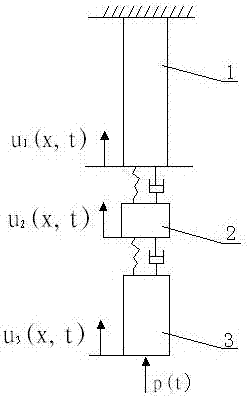

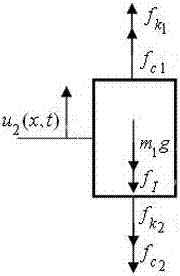

[0093] S1. According to the structural analysis of the downhole perforating tool and the analysis of the perforating process, the following assumptions are made: assuming that the materials of the tubing string and the perforating gun are uniform and isotropic; assuming that the shock absorber is a mass-spring-damping system, ignoring shock absorption The geometric shape of the packer and the inhomogeneity of mass distribution; the relative displacement between the packer and the tubing string is not considered, and it is regarded as a fixed support; the structural damping of the perforating string is ignored, and only the shock absorber and liquid damping ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

| Damping | aaaaa | aaaaa |

| Damping | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com