A hangable real-time control downhole gas-liquid separation combined lifting system

A gas-liquid separation and real-time control technology, which is applied in wellbore/well components, measurement, and production of fluids, etc., can solve the problems of lack of ground control function and poor applicability of oil wells, and achieves mature operation plan, efficient operation, The effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

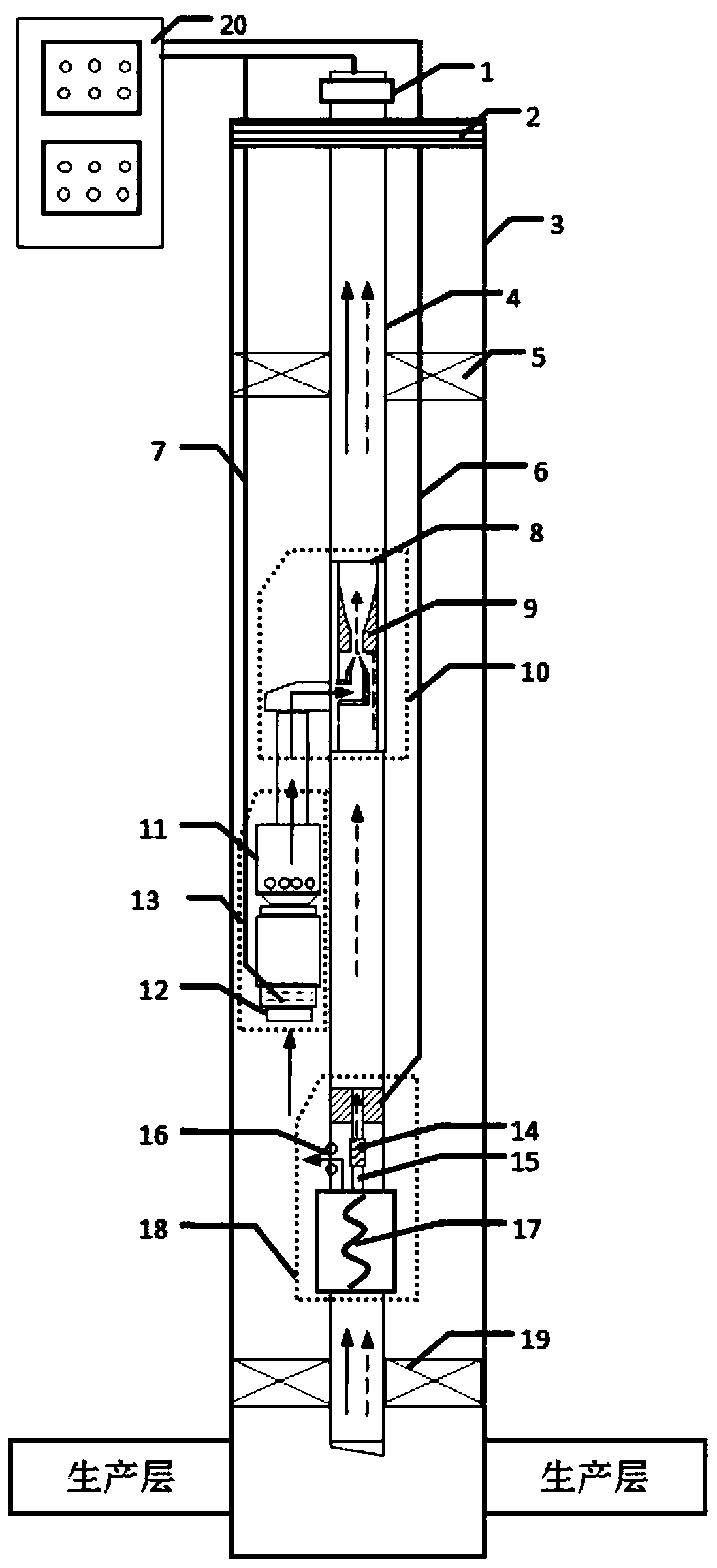

[0020] as attached figure 1 As shown, a suspension-type real-time control downhole gas-liquid separation combined lifting system includes an oil pipe 4 lowered into the casing 3, the top of the casing 3 is provided with an oil casing hanger 2, and the oil pipe The upper part of 4 is provided with a cable packer 5, and the lower part is provided with a top packer 19. The oil pipe 4 is connected with a suspended tee assembly 10, the suspended tee assembly 10 is provided with a jet pump lifting system, and the first port of the lower end of the suspended tee assembly 10 is suspended with an electric pump Lifting system assembly 13, the second port at the lower end of the suspended tee assembly 10 is a gas inlet, which communicates with the gas production oil pipe, and the lower end of the gas production oil pipe is connected with a gas-liquid separation system assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com