A kind of preparation method of highly efficient sulfur-doped zinc oxide nanomaterial

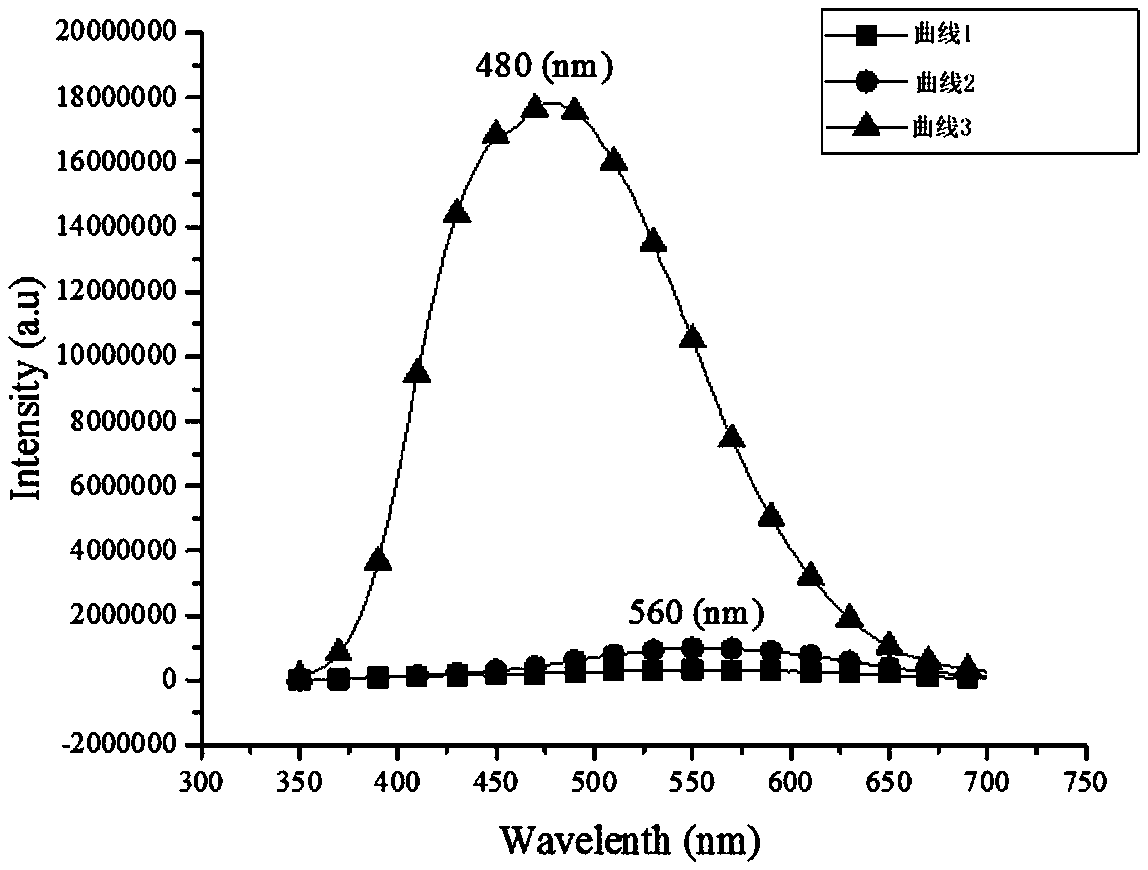

A zinc oxide nanometer and sulfur doping technology is applied in the field of preparation of zinc oxide nanomaterials, which can solve the problems of poor enhancement effect of fluorescent materials, difficult to achieve effective doping, and needs to be improved, so as to be beneficial to environmental protection and suitable for large-scale applications. The effect of large-scale industrial production and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Based on the above ideas, the present invention provides a method for preparing a highly efficient sulfur-doped zinc oxide nanomaterial, comprising the following steps:

[0035] S1: Preparation of nano zinc oxide precursor solution by precipitation method;

[0036] S2: At room temperature, add thioacetamide and ethylenediaminetetraacetic acid successively to the above-mentioned nano-zinc oxide precursor solution, and react at room temperature, and the reaction time is 1 to 5 hours;

[0037] S3: After the reaction is completed, the precipitate is separated, washed and dried to obtain white solid particles;

[0038] S4: heat-treating the above-mentioned white solid particles.

[0039] According to the present invention, the specific steps of preparing the nano-zinc oxide precursor solution in step S1 are: at room temperature, dissolving the zinc salt into water to form a salt solution, then adding the alkali metal hydroxide solution dropwise to the salt solution, stirrin...

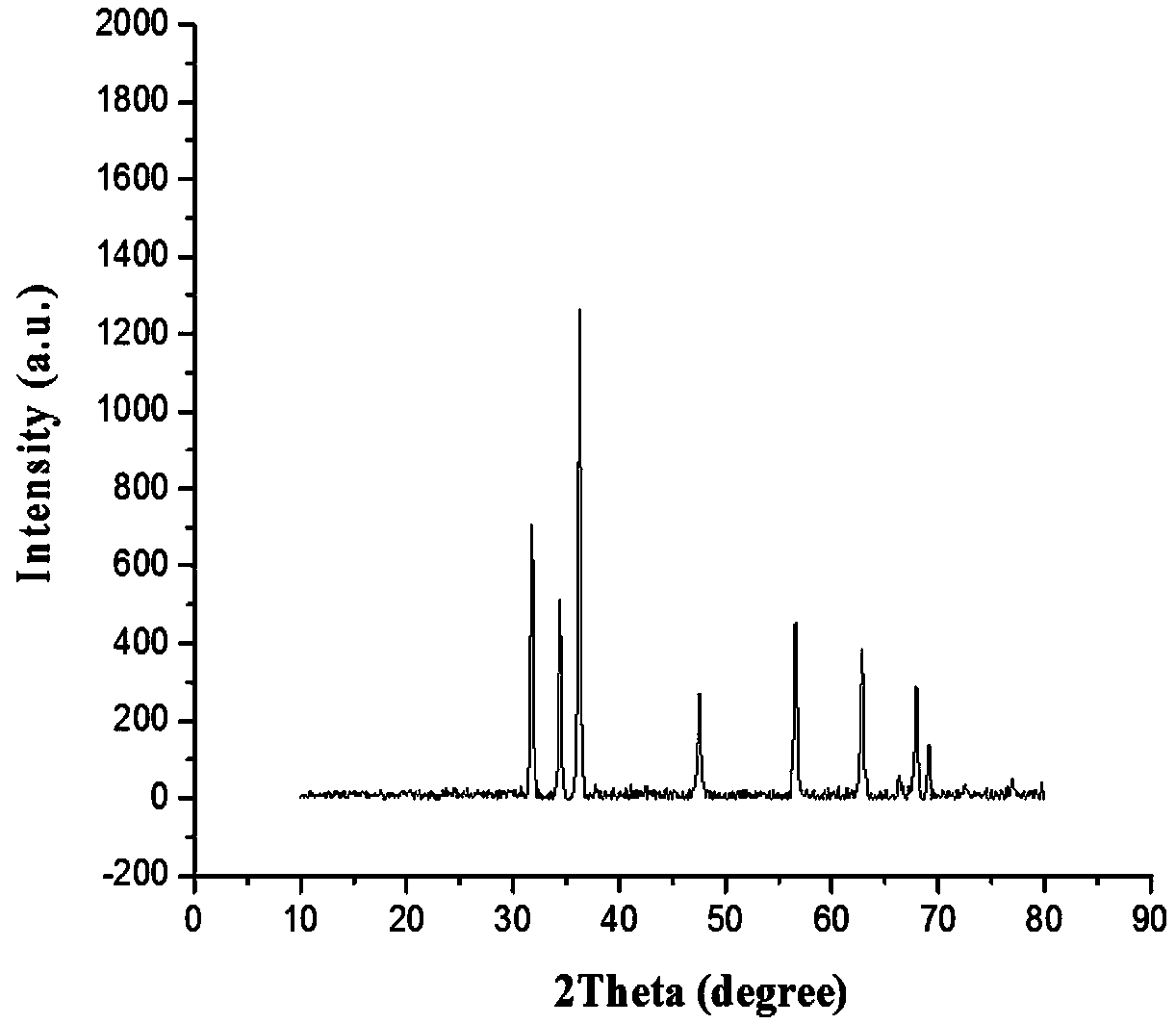

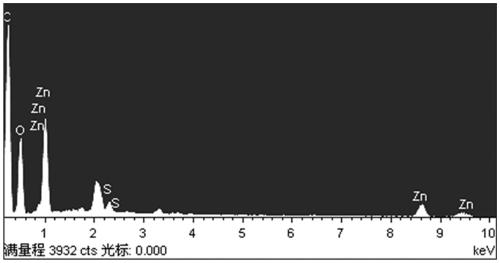

Embodiment 1

[0059] A preparation method of highly efficient sulfur-doped zinc oxide nanomaterials, the steps are:

[0060] (1) At room temperature, dissolve zinc acetate in water to prepare 0.2mol / L Zn(CH 3 COO) 2 2H 2 O solution;

[0061] (2) At room temperature, prepare a NaOH solution with a concentration of 0.2mol / L;

[0062] (3) At room temperature, NaOH solution was quickly added dropwise to Zn(CH 3 COO) 2 2H 2 In the O solution, stir and mix uniformly to obtain a suspension, which is the nano-zinc oxide precursor solution; wherein Zn(CH 3 COO) 2 2H 2 The volume ratio of O solution and NaOH solution is 1:1;

[0063] (4) At room temperature, prepare a thioacetamide solution with a concentration of 0.2mol / L;

[0064] (5) At room temperature, quickly drop the above-mentioned thioacetamide solution into the above-mentioned suspension, and stir to obtain a white suspension solution;

[0065] (6) Prepare an EDTA solution with a concentration of 0.01mol / L, pour the EDTA solution...

Embodiment 2

[0072] A preparation method of highly efficient sulfur-doped zinc oxide nanomaterials, the steps are:

[0073] (1) Dissolve zinc chloride in water to prepare 0.1mol / L zinc chloride solution at room temperature;

[0074] (2) At room temperature, prepare a NaOH solution with a concentration of 0.1mol / L;

[0075] (3) At room temperature, quickly drop the NaOH solution into the zinc chloride solution, stir, and mix evenly to obtain a suspension, which is the nano-zinc oxide precursor solution; the volume ratio of the zinc chloride solution to the NaOH solution is 1:0.5;

[0076] (4) At room temperature, prepare a thioacetamide solution with a concentration of 0.1mol / L;

[0077] (5) At room temperature, quickly drop the above-mentioned thioacetamide solution into the above-mentioned suspension, and stir to obtain a white suspension solution;

[0078] (6) Prepare an EDTA solution with a concentration of 0.01mol / L, pour the EDTA solution into the white suspension solution, and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com