Emergency discharge device for toughening furnace and discharge method

A kind of tempering furnace and emergency technology, applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of furnace blocking and sticking, manual operation is prone to errors, etc., and achieves the effect of improving efficiency, saving labor, and avoiding clutter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in combination with specific embodiments.

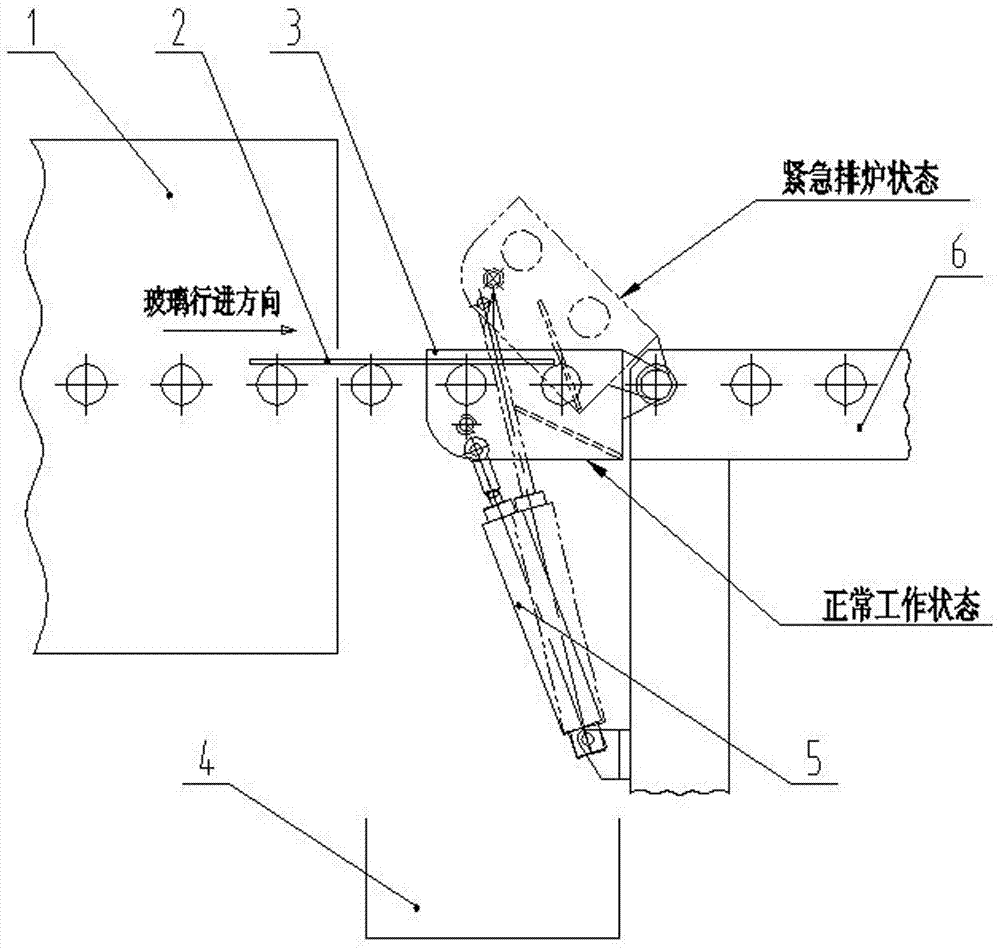

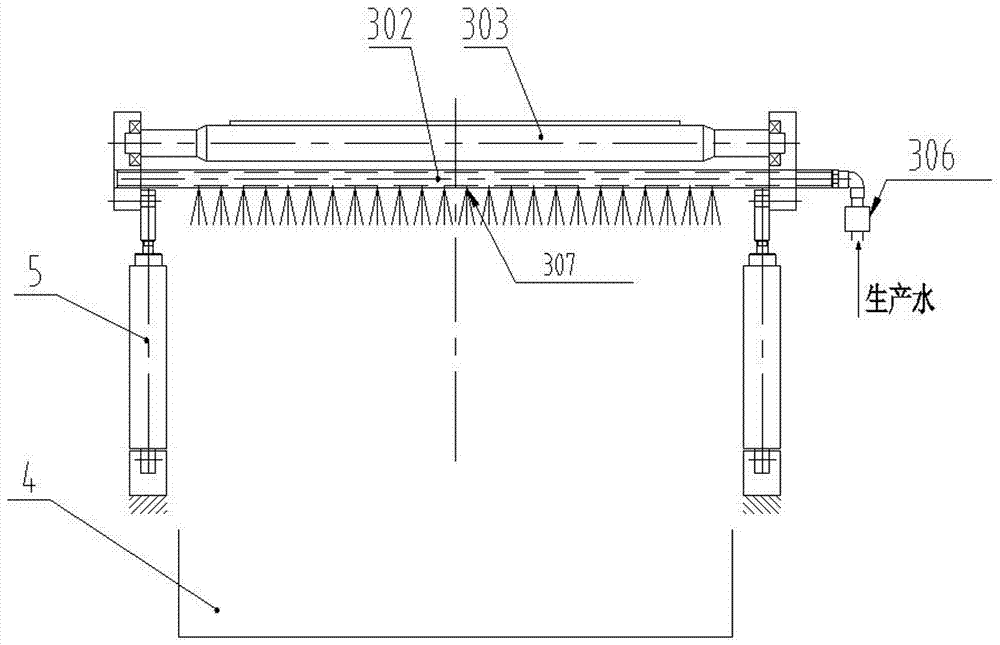

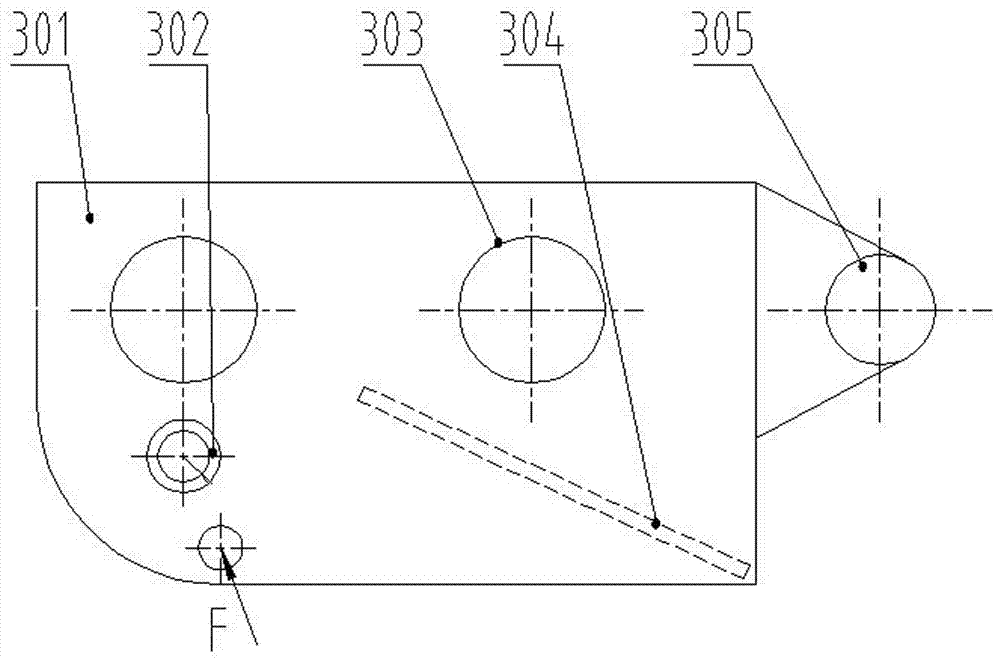

[0021] As shown in the figure: an emergency furnace exhaust device for tempering furnace, characterized in that: the device is equipped with a turning mechanism 3, a driving device 5, a cullet collecting car 4 and a film setting platform 6, and the film setting platform 6 is set on At the outlet end of the heating furnace 1, the turning mechanism 3 is arranged between the film setting table 6 and the heating furnace, and the driving device 5 is arranged at the bottom of the turning mechanism 3, so that the turning mechanism 3 can rotate upwards around the film setting platform 6 by 0~90 degrees, The bottom of the overturning mechanism 3 is provided with a cullet collection car 4; The film platform 6 is connected, and the two ends of the conveying roller table 303 are arranged on the turning frame 301, and are parallel to the conveying guide rollers of the heating furnace 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com