End-holding type transfer device for cylindrical products

A transfer device, cylindrical technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of low transfer efficiency, low transfer efficiency, low reliability, etc., to improve efficiency and reduce docking accuracy. requirements, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail:

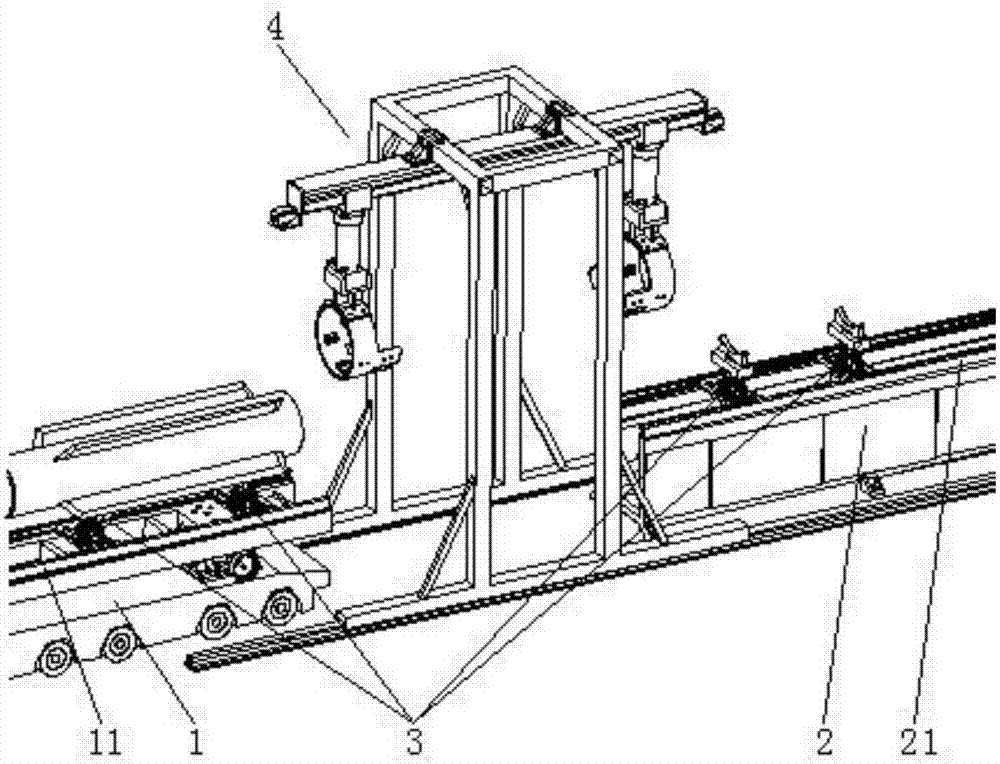

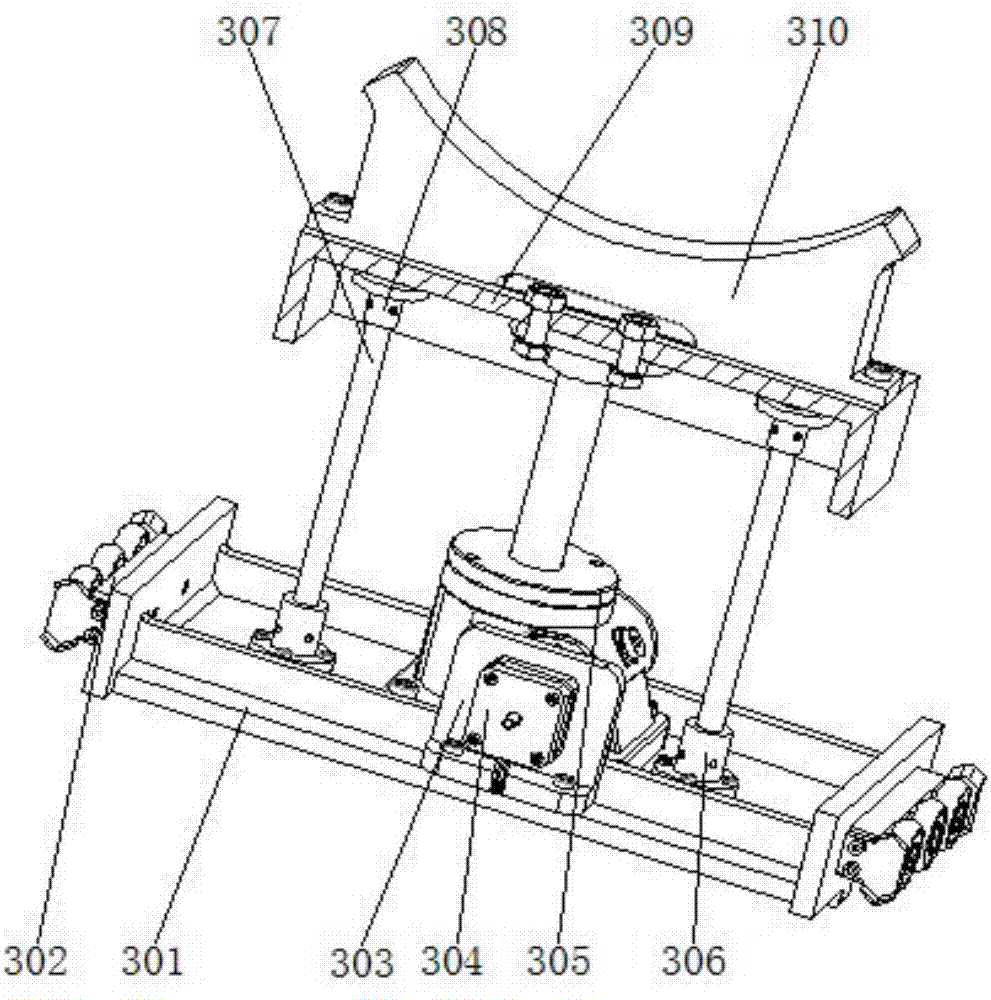

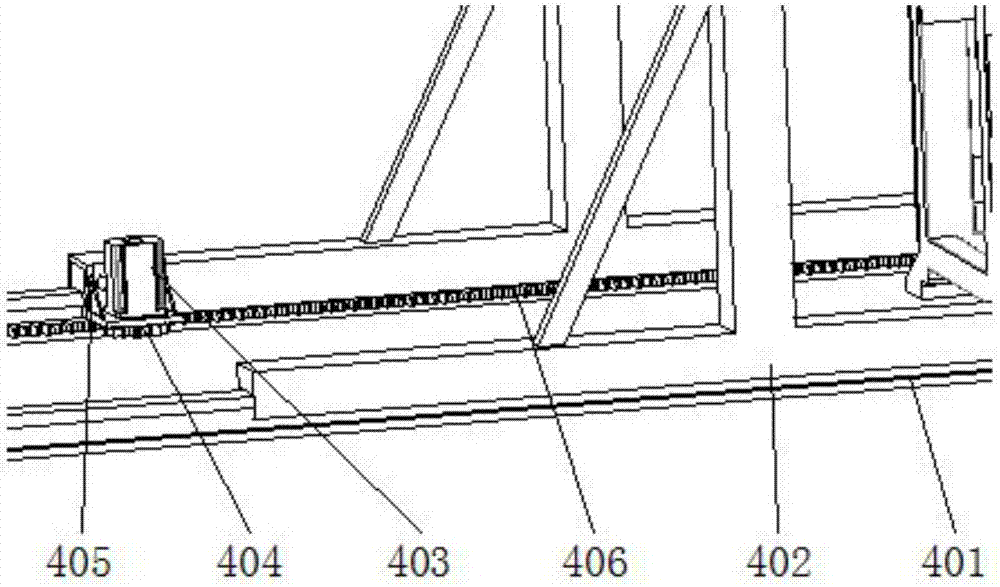

[0032] see figure 1 , an end-hugging transfer device for cylindrical products, including a moving base 1, a static base 2, a bracket 3 and a transfer mechanism 4, wherein: the upper surface of the moving base 1 is provided with two Parallel motion base guide rails 11; the upper surface of the base body of the static base 2 is provided with two parallel static base guide rails 21; the bracket 3 includes a horizontal movement mechanism and a lifting mechanism installed on its upper end for carrying the cylinder to be transferred. shape parts and realize their horizontal and lifting movements; the transfer mechanism 4 includes a walking mechanism and a ring-shaped holding mechanism installed on it, which is used to hold the ends of the cylindrical parts to be transferred and realize translational transfer; the moving base 1 The plane of symmetry between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com