Logistics and warehousing goods shelf

A technology for display racks and items, which is applied in the field of display racks for logistics and storage items, can solve problems such as unsuitable for large-scale use, difficulty in accessing goods, and low space utilization, and achieve broad application prospects and economic value. Convenient goods The effect of high access means and space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

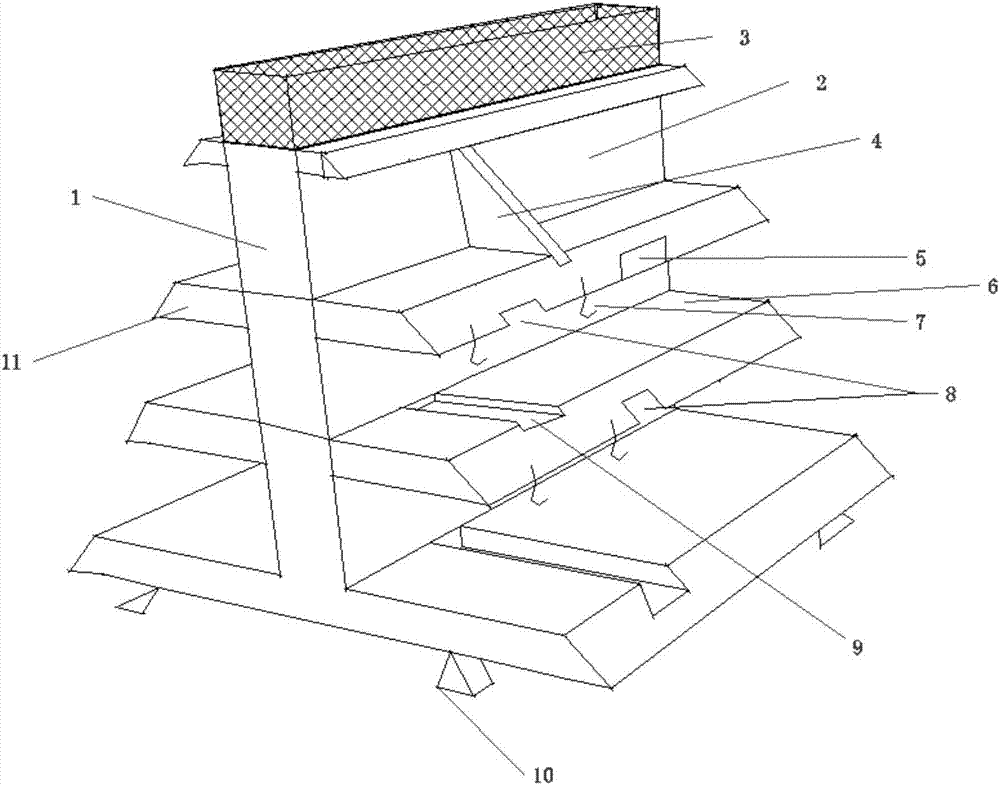

[0027] The technical solution adopted in the present invention is: a display rack for logistics storage items, including two telescopic rods with several single sections 1, and the top of each single rod 1 is welded with an expansion rod 11, corresponding to one of the expansion rods 11. There is a placement plane 6 between them, and a left and right partition plate 2 is arranged between the single rods 1 to separate the placement plane 6, and the uppermost placement plane 6 is welded with a limit frame 3 around it.

[0028] Further, the deployment rod 11 is vertically welded to both sides of the single rod 1 .

[0029] According to the above technical solution, when in use, the situation of toppling to one side does not occur, and the overall structure of the product is stable and firm.

[0030] Further, the limit frame 3 is vertically welded to the edge of the placement plane 6, and the limit frame is in the form of a mesh.

[0031] According to the above technical solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com