An Assembly-Oriented Quick-Change Gripper for Frame Parts

A gripper, quick-change technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

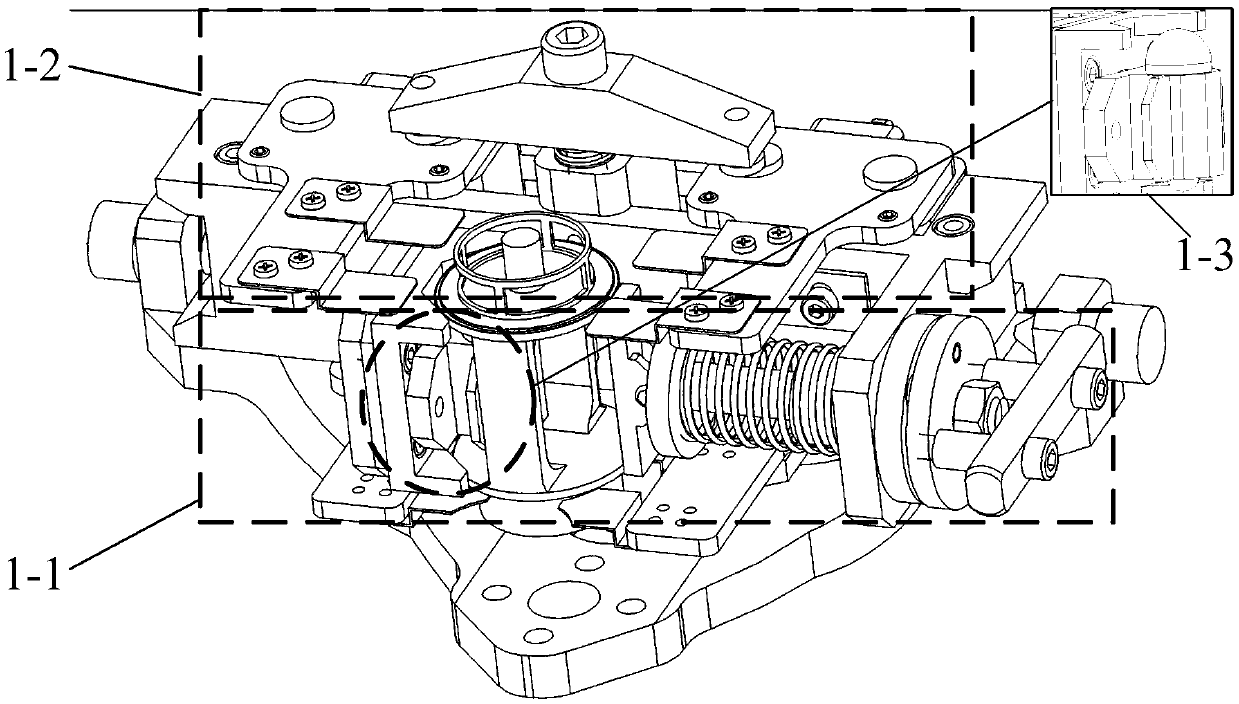

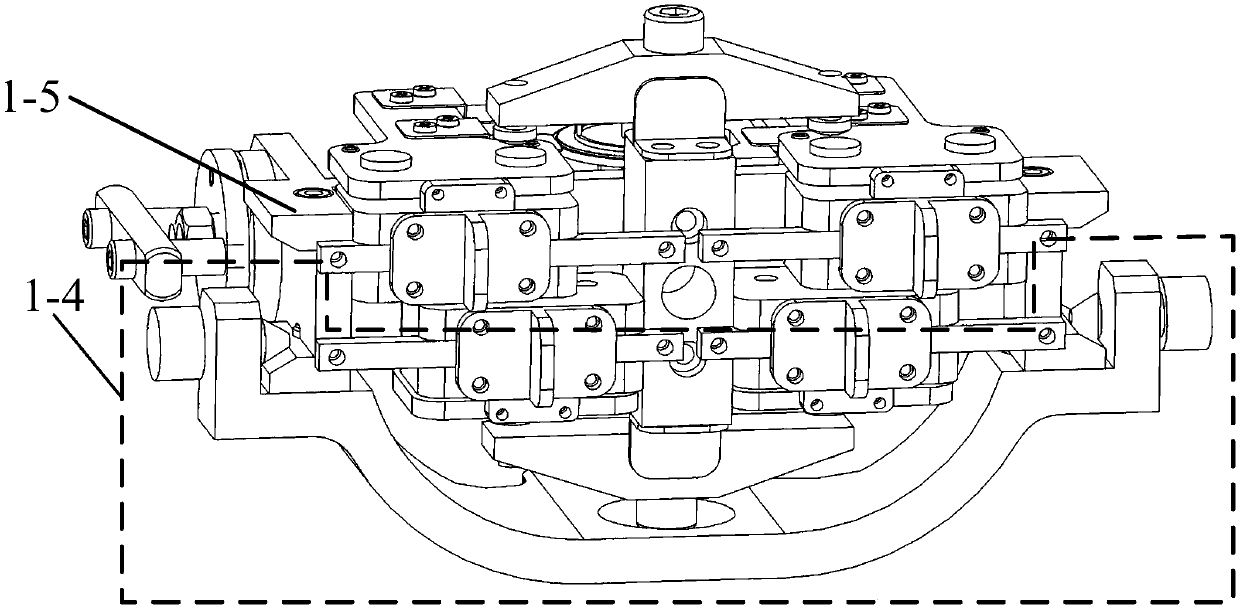

[0033] as attached figure 1 As shown, the present invention provides a quick-change clamp for frame parts facing assembly, the clamp includes a mounting frame 1-5, a circumferential positioning clamping mechanism 1-1, an axial support mechanism 1-3, After assembly, fix the pressing mechanism 1-2 and the quick-change locking mechanism 1-4;

[0034] as attached Figure 4 As shown, there are two parallel mounting plates on the mounting frame 1-5, and the two ends of the mounting frame 1-5 are processed with locking holes corresponding to the locking screws 5-3 on the quick-change locking mechanism 1-4. The upper and lower surfaces of the mounting frame 1-5 are symmetrically processed with positioning pin holes;

[0035]The circumferential positioning clamping mechanism 1-1 is installed on the mounting plate of the mounting frame 1-5, the frame part 1 is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com