Shear-stress-reduction anchoring structure and construction method thereof

A technology of anchoring structure and anchoring section, which is applied in foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of small shear deformation, damaged anchoring structure, and too conservative anchoring structure, so as to achieve the effect of not easy to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

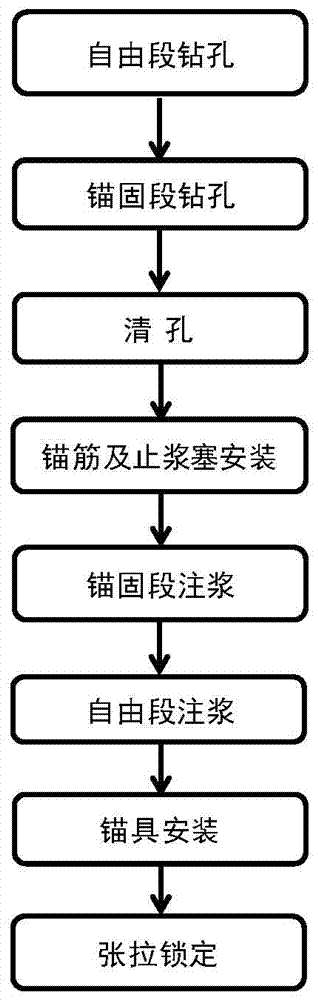

[0036] Such as figure 1 Shown is a schematic structural view of an embodiment of the shear-type anchoring structure of the present invention. The scissor-type anchoring structure of this embodiment includes a free section borehole 1 , and an anchor section borehole 2 is provided on the inner bottom surface of the free section borehole 1 . The borehole 1 in the free section extends inward to the inside of the potential slip surface 3 of the slope body 11, and the boreholes 2 in the anchor section are all located in the stable rock mass inside the potential slip surface 3 of the slope body, and the borehole 1 in the free section and the anchor section An anchor bar 4 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com