Production device for extraction of aromatic plant components and production method thereof

A technology of aromatic plants and production equipment, which is applied in the field of separation, can solve the problems of low efficiency, achieve the effects of reducing costs, increasing plant utilization, and improving the extraction rate of essential oils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: the extraction of rose essential oil

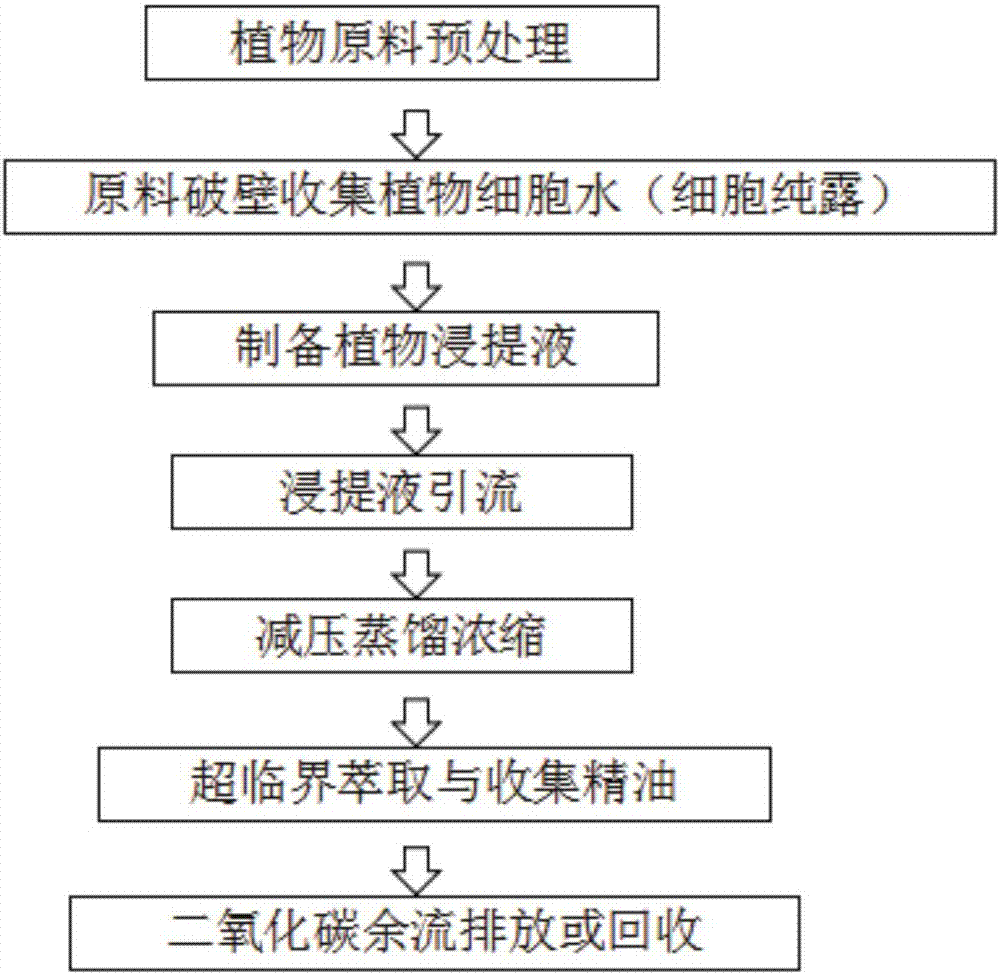

[0065] 1) Pretreatment of plant raw materials: The picking time is before 10:00 in the morning. Pick the roses that are fully open, remove the stamens and pedicles of the flowers, and collect fresh petals.

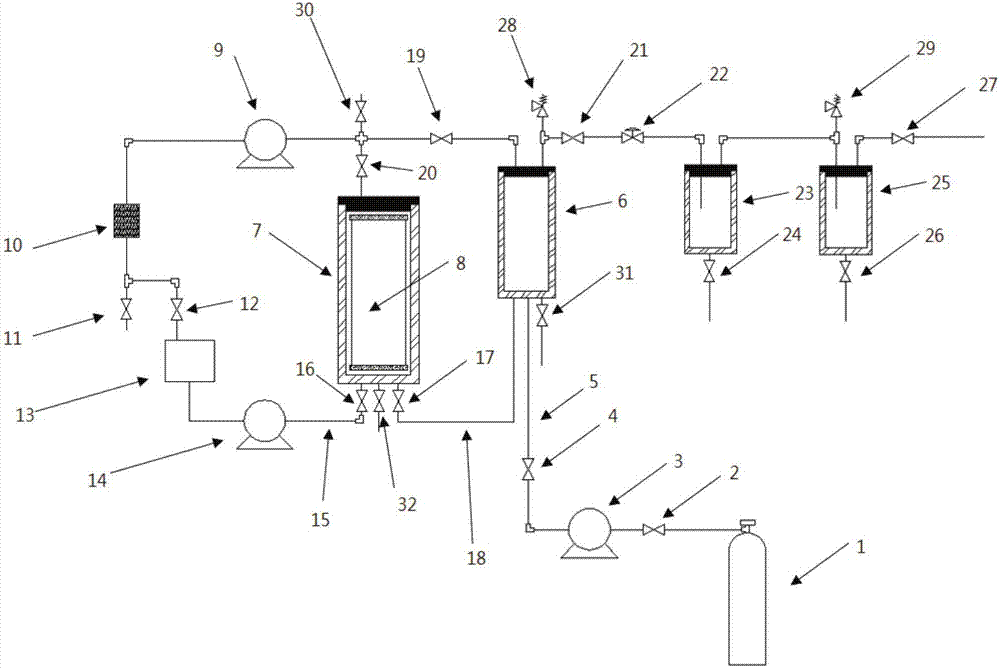

[0066] 2) Collect plant cell water (cell hydrosol) by breaking the raw material wall: Weigh 10Kg of plant tissue and put it into the filter 8 in the raw material kettle, then put it into the raw material kettle 7, set the temperature of the raw material kettle 7 at 35°C, and open the vacuum valve 20 is connected to the vacuum pump 9 to continuously vacuumize the raw material kettle 7 for a long time, and the extracted gas is collected by the cell water collection valve 11 through the liquid condensed by the condenser 10, and the collected liquid is rose cell water (rose hydrosol). Close the vacuum pump 9 after obviously condensate flows out and open the vacuum breaking valve 30 to break the vacuum, and now the raw...

Embodiment 2

[0072] Embodiment 2: the extraction of lavender essential oil

[0073] 1) Pretreatment of plant raw materials: the fixed picking time is before 10:00 in the morning, picking mature lavender, removing impurities and dead leaves;

[0074] 2) Collect plant cell water (cell hydrosol) by breaking the raw material wall: Weigh 10Kg of plant tissue and put it into the filter 8 in the raw material kettle, then put it into the raw material kettle 7, set the temperature of the raw material kettle 7 at 35°C, and open the vacuum valve 20 is connected with vacuum pump 9 to continuously evacuate the raw material kettle 7 for a long time, and the extracted gas is collected by the cell water collection valve 11 through the liquid condensed by the condenser 10, and the collected liquid is lavender cell water (lavender hydrosol). Close the vacuum pump 9 after obviously condensate flows out and open the vacuum breaking valve 30 to break the vacuum, and now the raw material in the raw material ket...

Embodiment 3

[0080] Embodiment 3: the extraction of sweet-scented osmanthus essential oil

[0081] 1) Pretreatment of plant raw materials: the fixed picking time is before 10:00 in the morning, and the mature osmanthus is picked to remove impurities;

[0082]2) Collect plant cell water (cell hydrosol) by breaking the raw material wall: Weigh 10Kg of plant tissue and put it into the filter 8 in the raw material kettle, then put it into the raw material kettle 7, set the temperature of the raw material kettle 7 at 40°C, and open the vacuum valve 20 is communicated with vacuum pump 9 to raw material kettle 7 and continues to vacuumize for a long time, and the liquid that the extracted gas is condensed by condenser 10 is collected by cell water collection valve 11, and the liquid that collects is sweet-scented osmanthus cell water (osmanthus fragrans hydrosol). Close the vacuum pump 9 after obviously condensate flows out and open the vacuum breaking valve 30 to break the vacuum, and now the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com