Material mixing machine for manufacturing food packaging bags

A packaging bag and mixing machine technology, applied in the field of mechanical equipment, can solve problems such as uneven mixing, and achieve the effect of uniform and uniform mixing of materials

Inactive Publication Date: 2017-11-28

广德美好包装科技有限公司

View PDF10 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention aims at the above-mentioned existing technical problems, and provides a mixing machine for making food packaging bags to solve the problem of uneven mixing in current plastic mixing machines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the technical scheme of the present invention will be further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

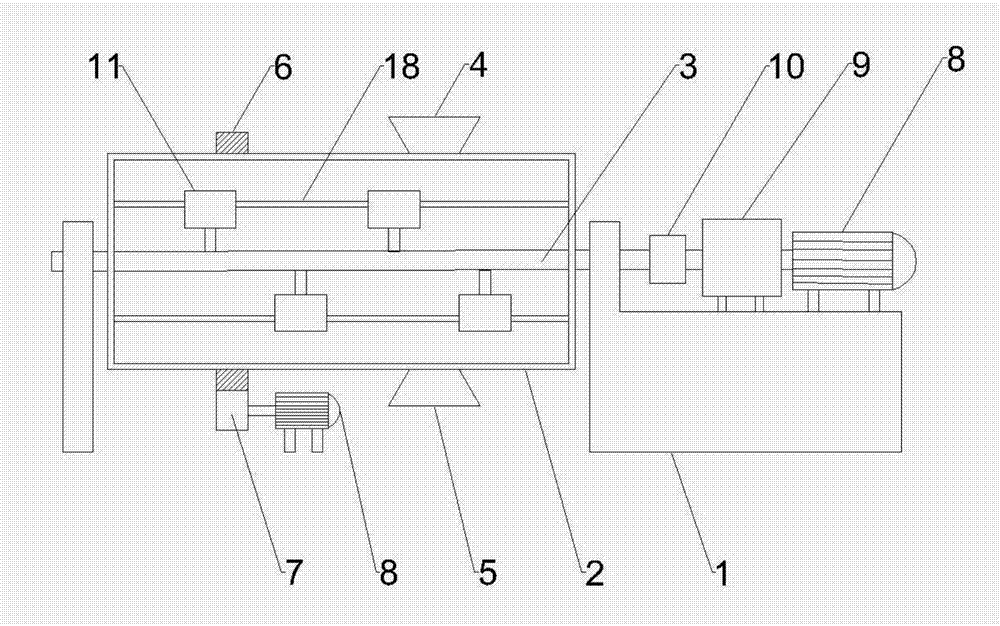

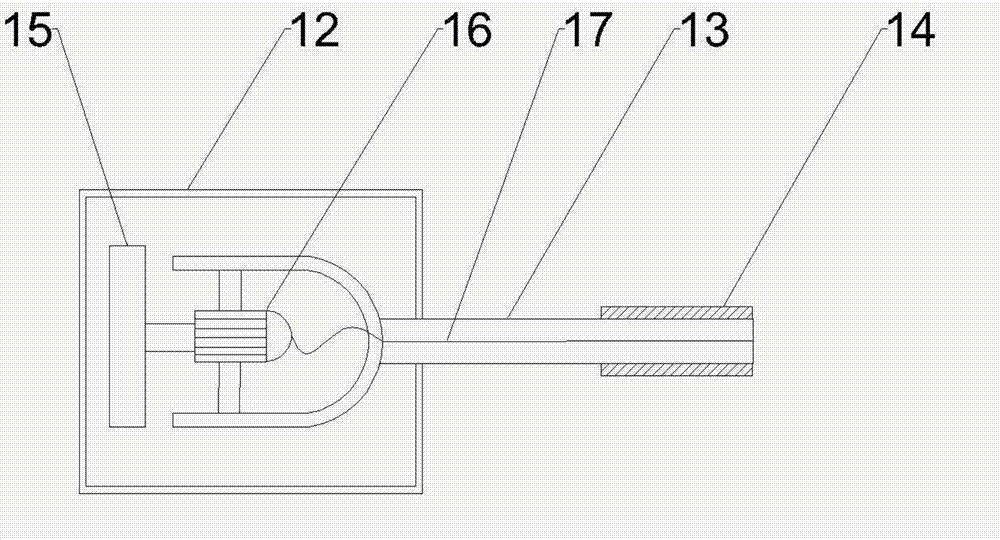

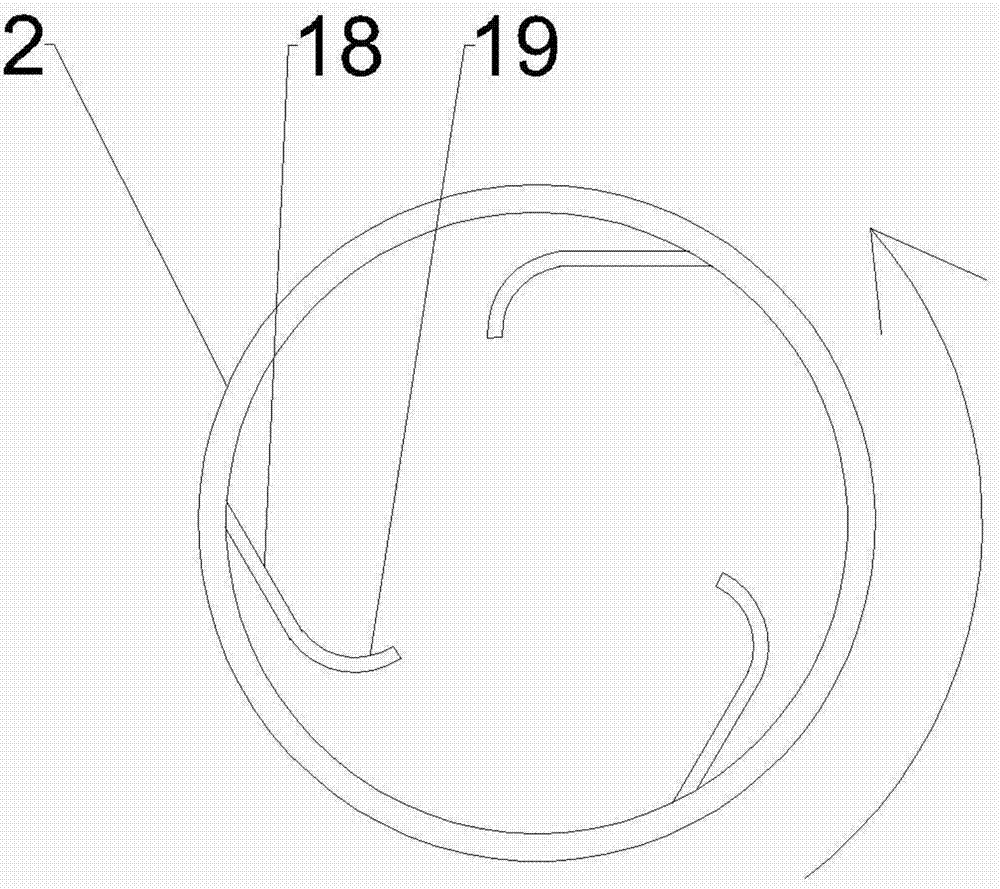

The invention discloses a material mixing machine for manufacturing food packaging bags, and belongs to the field of mechanical equipment. The material mixing machine comprises a rack, a horizontally-placed material mixing barrel is arranged on the rack, a rotating shaft is arranged at the axis position in the material mixing barrel, is rotationally connected with the rack, and is rotationally connected with the material mixing barrel, a driven gear is annularly arranged outside the material mixing barrel, a driving gear is arranged below the material mixing barrel, and the driving gear is meshed with the driven gear; the rotating shaft and the driving gear are driven by a motor to rotate, the rotating directions of the rotating shaft and the material mixing barrel are opposite, a vibrating blade is arranged on the rotating shaft and comprises blades and stirring arms, the two ends of each stirring arm are connected with the rotating shaft and the corresponding blade correspondingly, an eccentric gear and an electromotor are arranged in each blade, and each eccentric gear is connected with the corresponding electromotor; and connected wires are arranged in the rotating shaft and the stirring arms, and the wires are connected with the electromotors. A material throwing plate is further arranged on the inner wall of the material mixing barrel. When the material mixing machine is used for mixing materials, the materials can be mixed more evenly.

Description

technical field [0001] The invention belongs to the field of mechanical equipment, and in particular relates to a mixing machine for making food packaging bags. Background technique [0002] Food packaging bags are a kind of packaging design. In order to keep fresh and store food in daily life, product packaging bags are produced. Food packaging bags refer to film containers that are in direct contact with food and are used to hold and protect food. Plastic bags are the most commonly used food packaging bags now, and in the process of plastic bags, a bag mixer is needed. It is used for mixing and coloring of polyvinyl chloride resin, coloring and drying of polyethylene and polypropylene particles, drying of hygroscopic resins such as ABS and polycarbon resin before molding, mixing of phenolic resin, etc. It is one of the necessary equipment for plastic processing plants. [0003] A Chinese utility model whose publication number is CN204820003U discloses a plastic mixer, c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29B7/16B29B7/08B29B7/22

CPCB29B7/08B29B7/16B29B7/22B29B7/106

Inventor 张建平

Owner 广德美好包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com