Swinging type rotation gas claw device

A rotary air claw and swinging technology, applied in the field of manipulators, can solve the problems of small application range, inability to install and use, and large limitations, and achieve the effect of large application range, small occupied space, and small rotating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

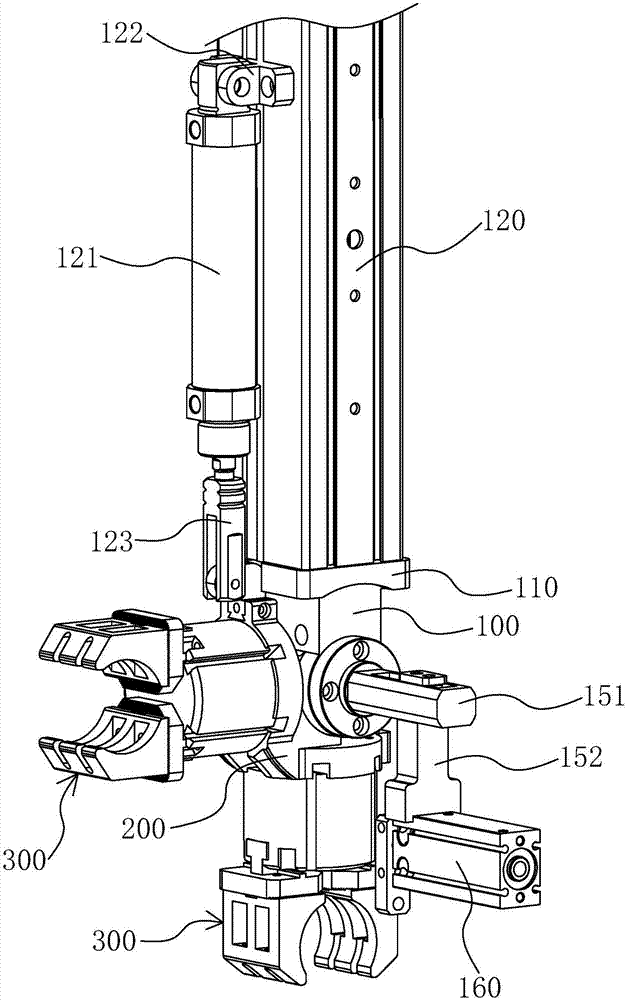

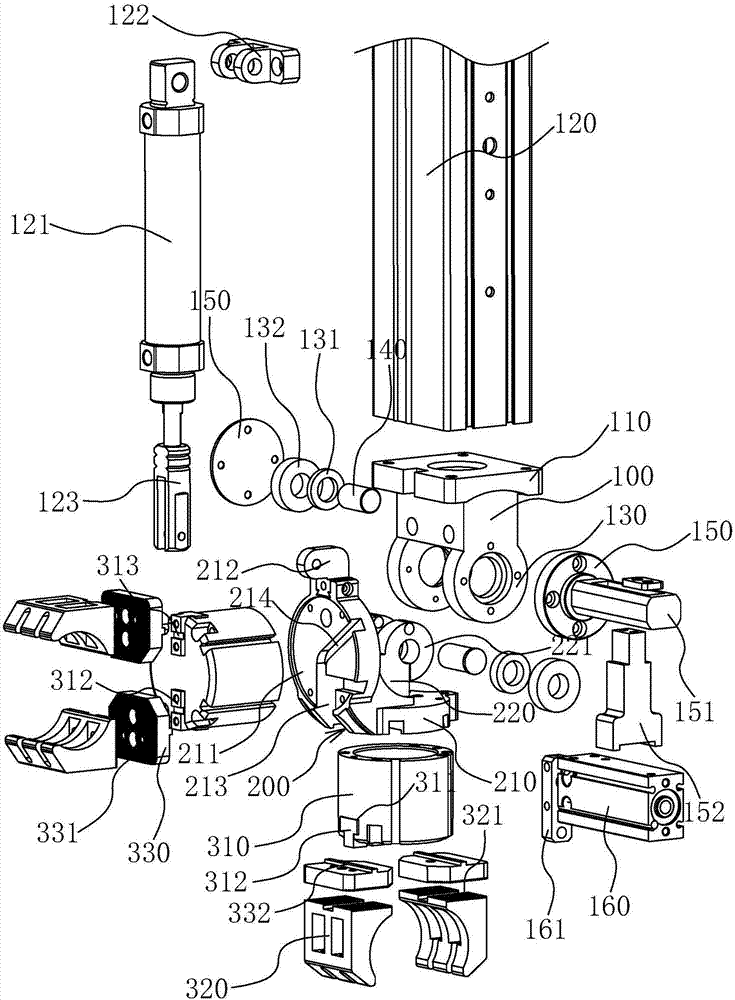

[0037] Such as figure 1 , figure 2 As shown, a swing type rotary air gripper 300 device of the present invention includes a fixed seat 100 , a rotating seat 200 and an air gripper 300 .

[0038] The fixed seat 100 is a square body block structure erected. The upper edge of the fixed seat 100 protrudes outwards and forms a fixed part 110 at the upper end of the fixed seat 100. The upper surface of the fixed part 110 is connected with the vertically arranged manipulator arm 120 Fixed connection, the rotating seat 200 is movably connected with the fixed seat 100 and can rotate relative to the fixed seat 100. There are two air grippers 300 and they are respectively connected with the rotating seat 200. The two air grippers 300 are perpendicular to each other and located in the same plane

[0039] In the initial state, one of the air grippers 300 is set horizontally, and the other air gripper 300 is set upright. The two air grippers 300 are located in the same horizontal plane. A...

Embodiment 2

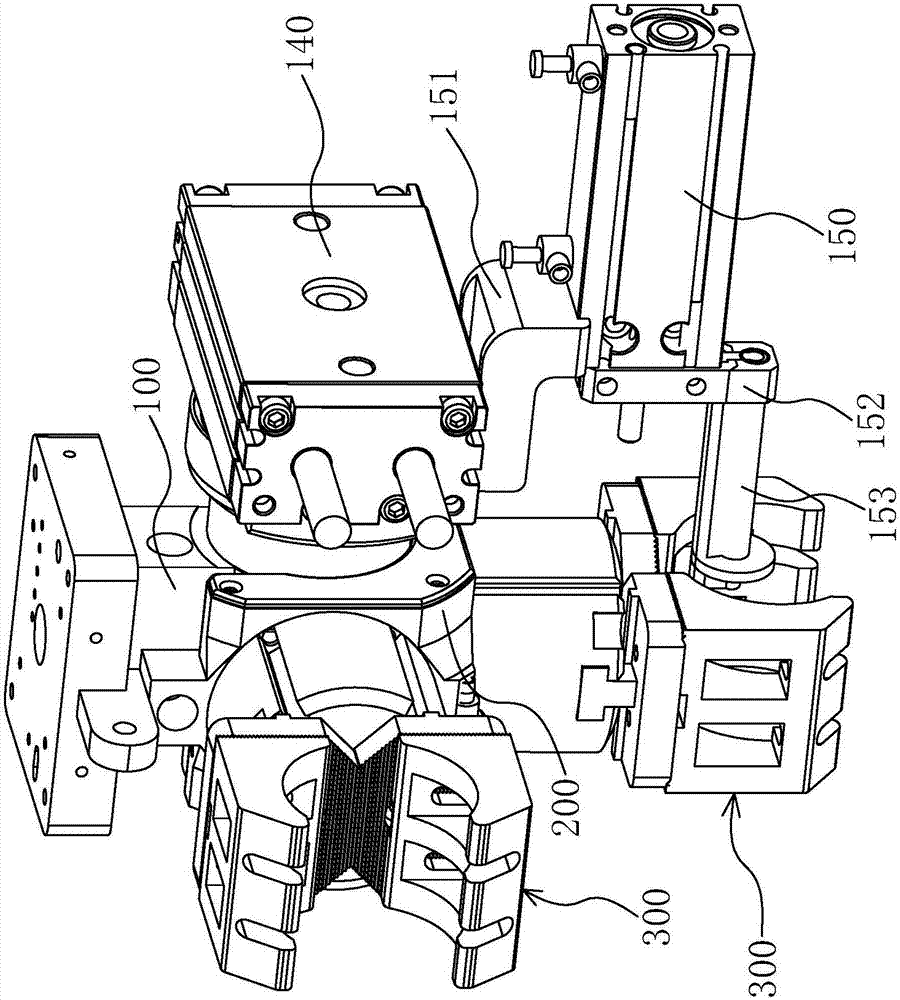

[0063] The inventive concept and working principle of this embodiment are basically the same as those of the embodiment, except that the structure of the rotating base 200, the connection structure between the rotating base 200 and the fixed base 100, and the driving method of the rotating base 200 are described in detail as follows:

[0064] Such as image 3 , Figure 4 As shown, a swing type rotary air gripper 300 device of the present invention also includes a fixed seat 100 , a rotating seat 200 and an air gripper 300 .

[0065] The structures of the fixed seat 100 and the air gripper 300 are the same as those in Embodiment 1, while the rotating seat 200 is similar to a plate-shaped structure, and its middle is bent in a right-angled arc shape, so that the two ends of the rotating seat 200 are perpendicular to each other, and one end is erected , the other end is arranged horizontally, and an installation groove 210 for installing the air gripper 300 is also provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com