Brake apparatus for capstan of winch

A technology of braking device and winch, which is applied in the direction of hoisting device, braking actuator, slack adjuster, etc., can solve the problem of affecting the working sensitivity and service life of modern equipment, increasing the cost of ship production and use, and affecting the normal use performance of ships. and other problems, to achieve the effect of ensuring work efficiency, simplifying the structure and lowering the maintenance threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

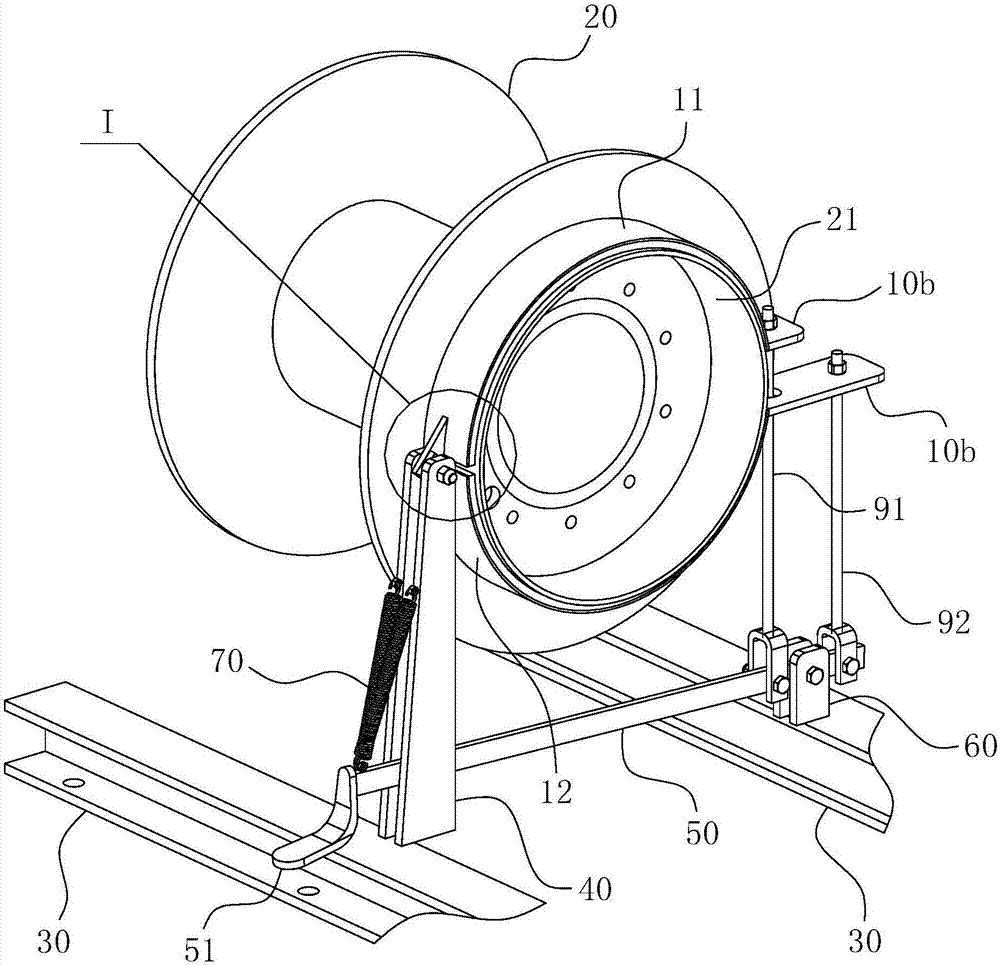

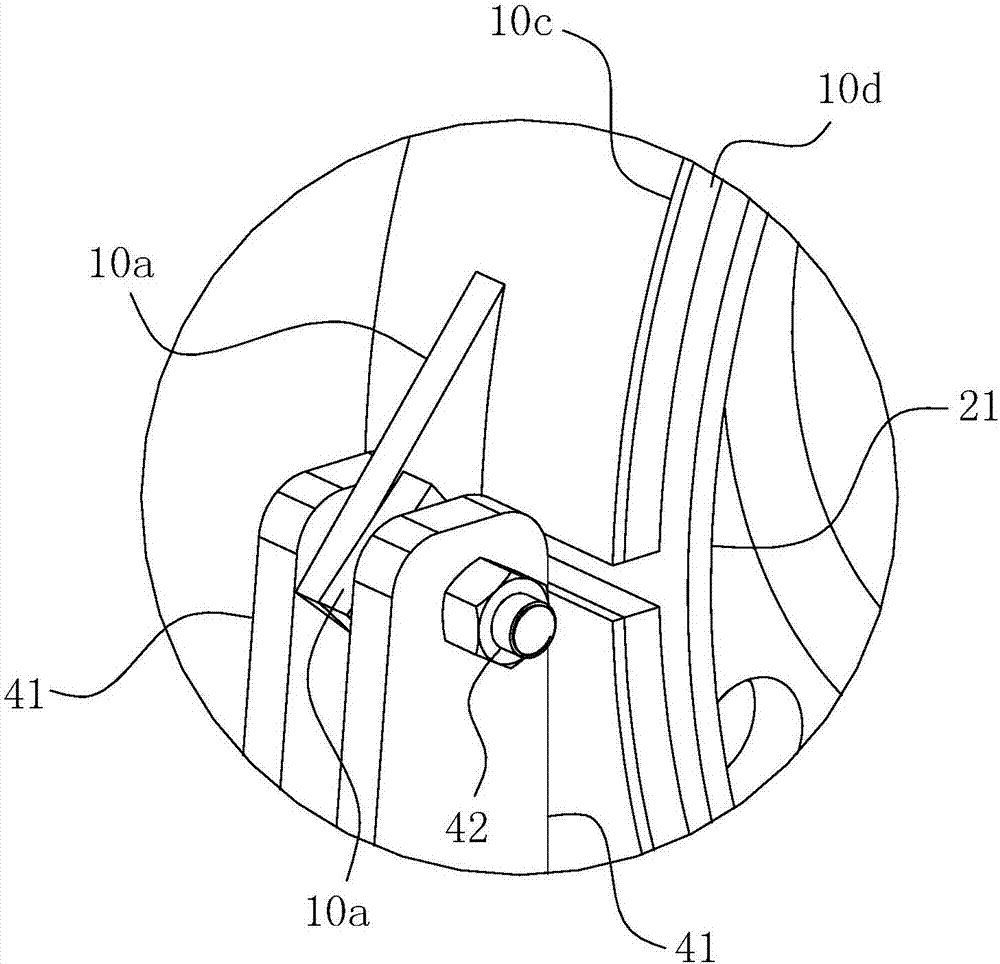

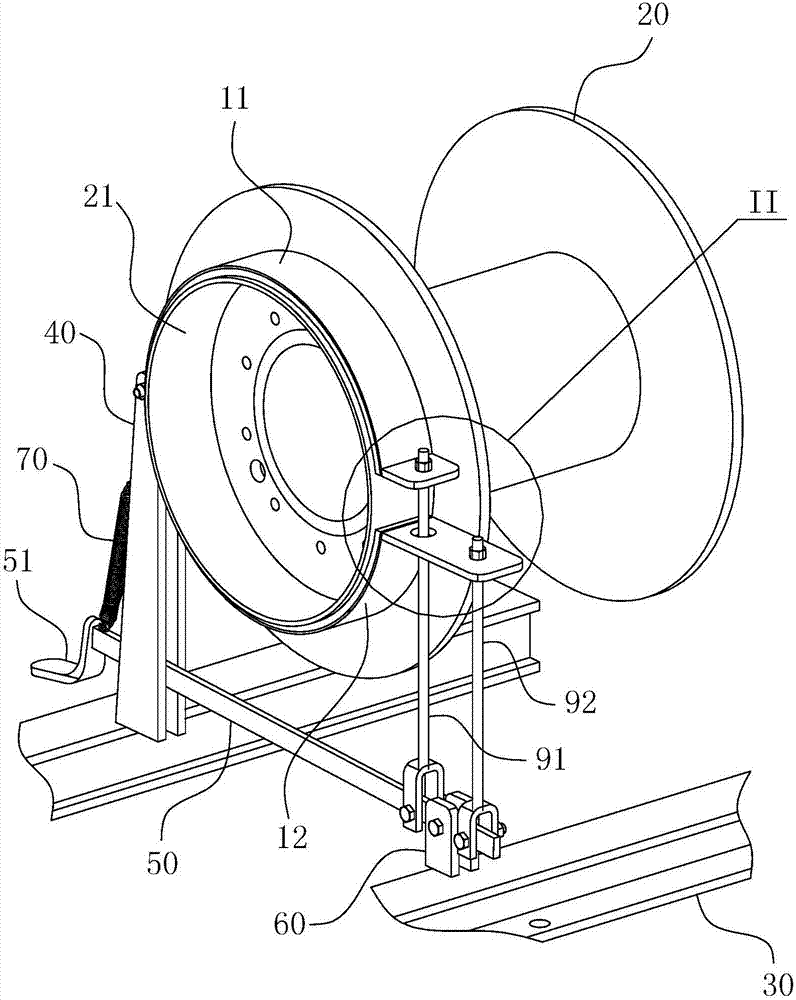

[0028] For ease of understanding, combined here Figure 1-4 , the concrete structure and working mode of the present invention are further described as follows:

[0029] The specific structure of the present invention is as Figure 1-4 As shown, its main structure includes a winch 20 with a matching ring 21 , a brake ring, a base 30 , a bracket 40 , a tension spring 70 , a pedal rod 50 , a pull rod and a hinged support 60 . During actual assembly, the brake ring is composed of two half-jointed brake arc plates, and the hinged ends at the same ends of the two brake arc plates are hinged on the bracket 40, and the other ends of the two brake arc plates are connected through the pull rod. Operated by the pedal lever 50, the opening and closing hinge action of the two brake arc plates is realized. Once the two brake arc plates produce the opening and closing action, the two brake arc plates can produce locking and loosening actions relative to the outer wall of the matching ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com