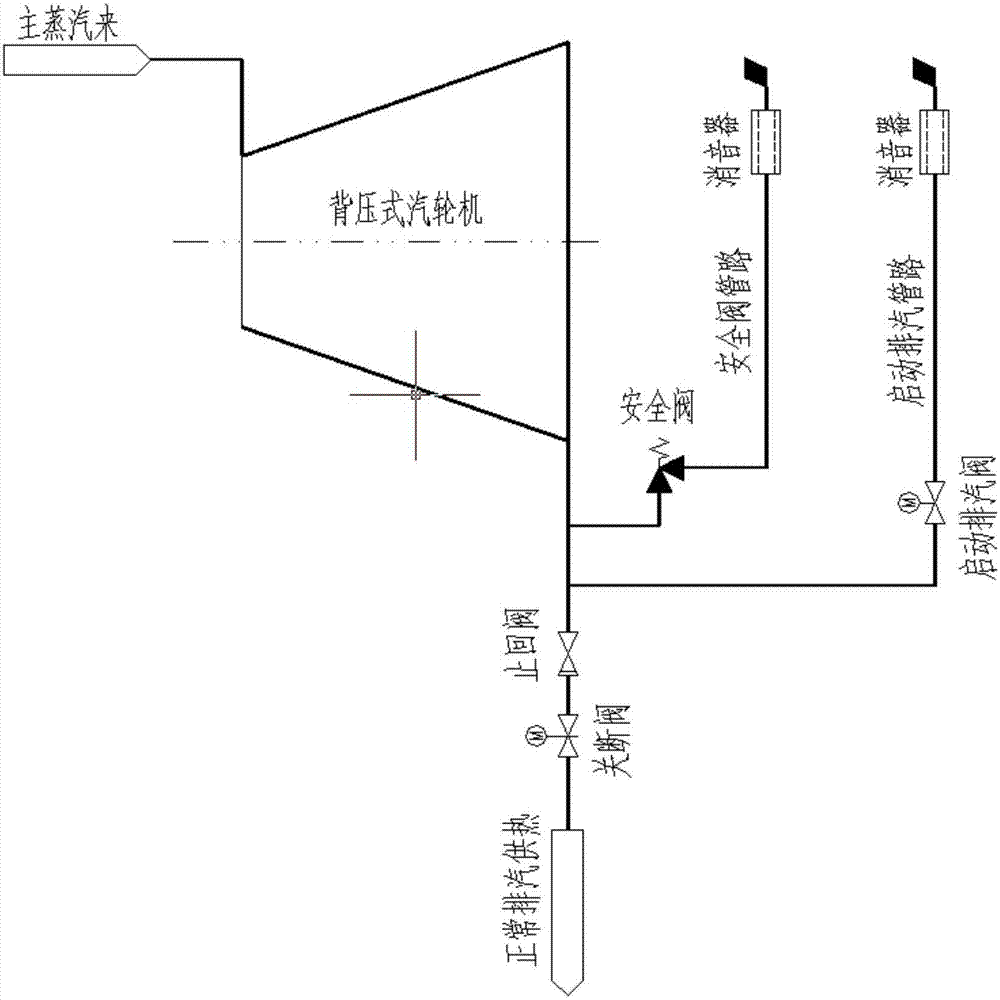

Back pressure steam turbine start exhaust recovery system

A recovery system and steam turbine technology, applied in steam recovery, steam engine installations, machines/engines, etc., can solve the problems of noise pollution, visual pollution, waste of working fluid, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

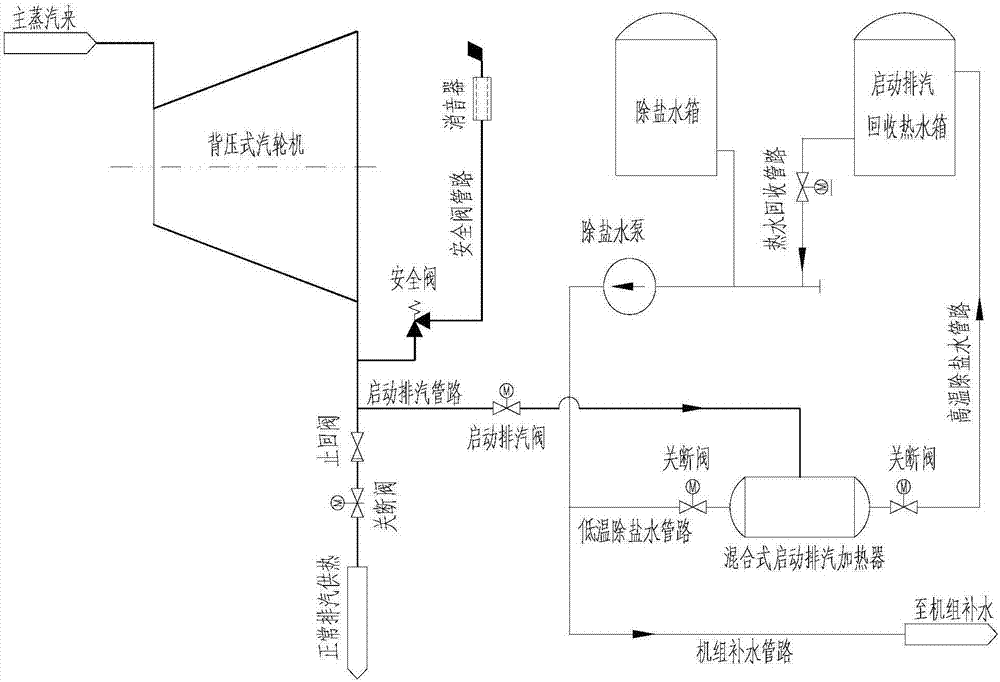

[0018] The present invention transforms and innovates on the basis of the conventional start-up exhaust steam system, and proposes a back pressure steam turbine start-up exhaust steam recovery system. Such as figure 2 As shown, the system includes a hybrid start-up exhaust steam heater, start-up exhaust steam recovery hot water tank, start-up exhaust steam pipeline, low-temperature desalinated water pipeline, high-temperature desalinated water pipeline and desalinated water tank. The hybrid starting exhaust steam heater is connected with the back pressure steam turbine through the starting exhaust steam pipeline. The hybrid start-up exhaust steam heater is connected to the start-up exhaust steam recovery hot water tank through a high-temperature desalinated water pipeline. The desalinated water tank is connected to the hybrid start-up exhaust steam heater through a low-temperature desalinated water pipeline.

[0019] After using the invention, during the start-up process of...

Embodiment 2

[0021] In this embodiment, a desalinated water pump and a shut-off valve are arranged sequentially between the desalted water tank and the hybrid start-up exhaust steam heater. A start-up exhaust valve is arranged on the start-up exhaust pipeline. A shut-off valve is provided on the high-temperature desalinated water pipeline.

[0022] All the rest are consistent with Example 1.

Embodiment 3

[0024] In this embodiment, a hot water recovery pipeline is connected to the startup exhaust steam recovery hot water tank, and the hot water recovery pipeline is connected to a low-temperature desalinated water pipeline.

[0025] All the rest are consistent with Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com