Monorail crane fore-extended supporting operation platform and method

An operating platform, forward exploration support technology, applied in earth-moving drilling, pillars/supports, mining equipment, etc., can solve the problems of time-consuming, labor-intensive, unfavorable safety management, etc., and achieve high efficiency, simplified operation procedures, and low processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

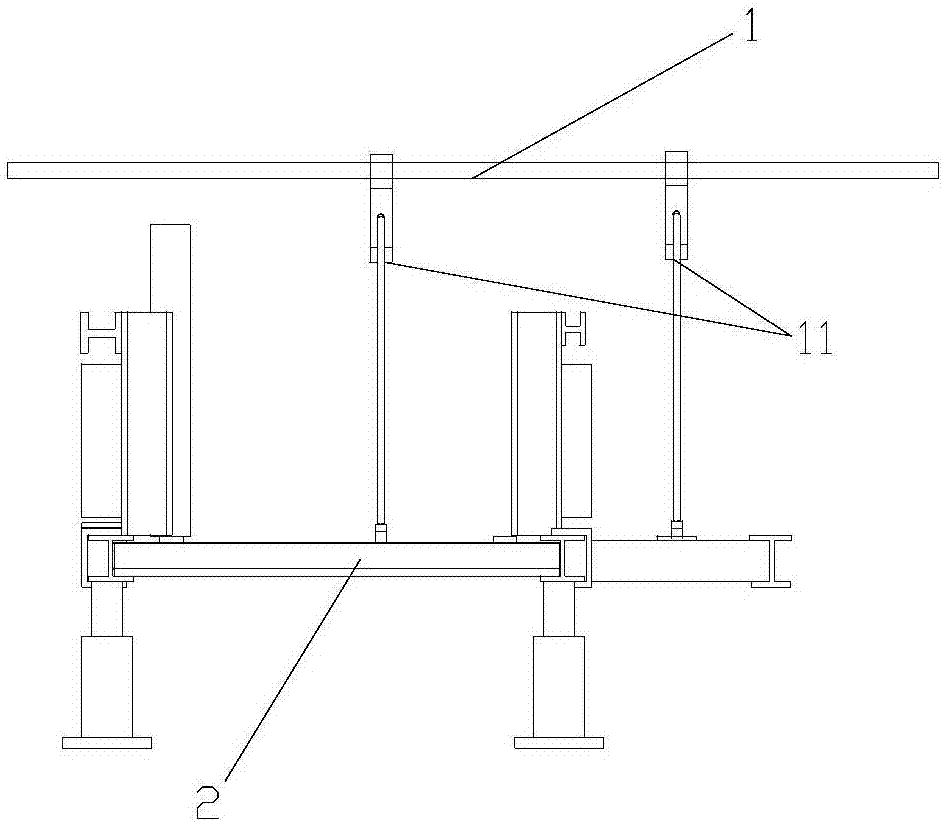

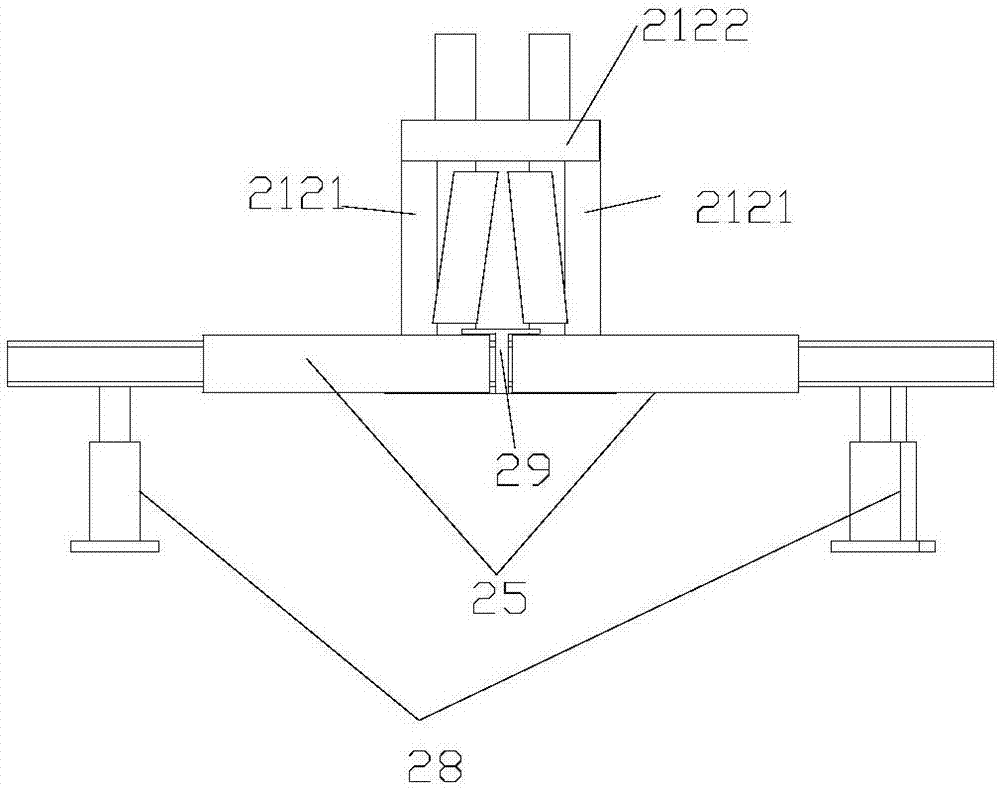

[0033] Such as figure 1 As shown, the present embodiment includes a monorail crane 1 and a scaffold 2; the scaffold 2 can be suspended under the monorail crane 1 with adjustable height and gradient; the scaffold 2 includes a middle part 21, a weight balance part 22, two wings 23, Two-wing opening and closing cylinder 24, two-wing guide rods 25, two-wing locking devices 26, advanced temporary support devices 27, and several supporting legs 28; the middle part 21 is at the middle position of the scaffold 2; the weight balance part 22 is behind the middle part 21 Side; described two wings 23 comprise left wing and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com