Earth pressure cell embedding device and earth pressure cell embedding method adopting device

An earth pressure box and earth support technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of uncoordinated lateral deformation, affecting measurement results, and low installation efficiency, so as to reduce test errors, Guaranteed accuracy and reduced twisting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

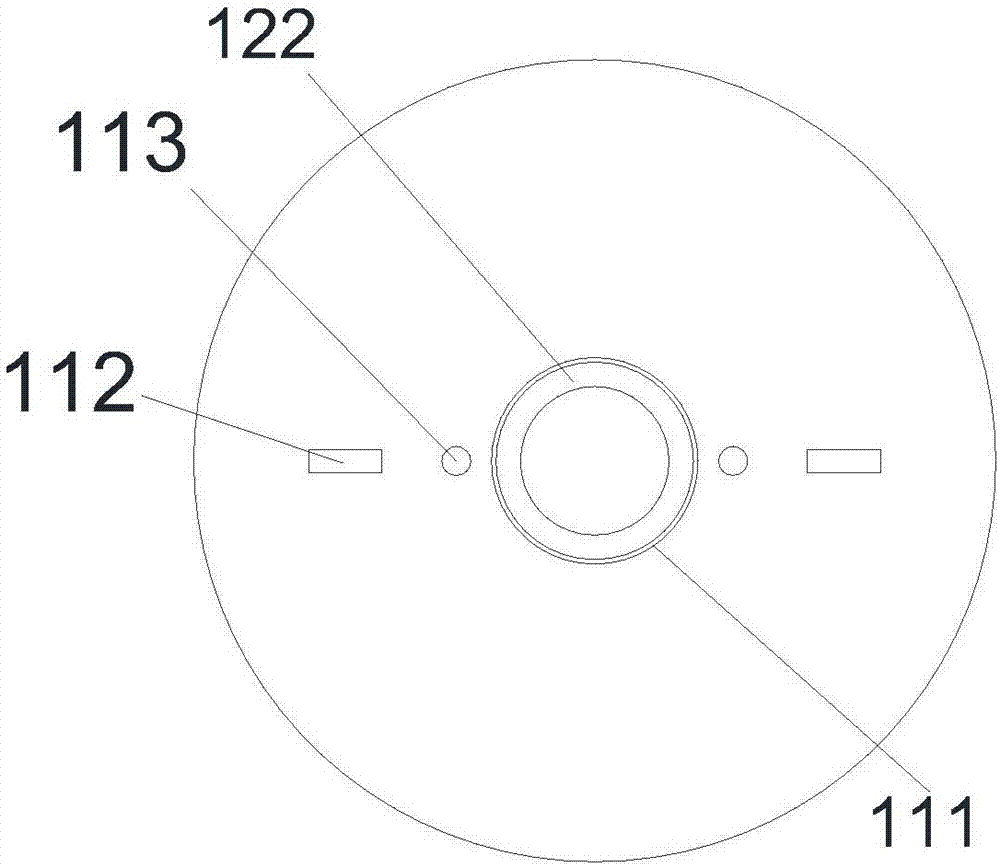

[0054] Such as figure 1 As shown, an earth pressure cell embedding device includes an embedding cylinder, an embedding rod assembly and a hoisting rope 300, figure 2 is a schematic top view of the buried barrel of this embodiment, wherein:

[0055] Described embedding tube comprises soil-putting tube 110, bulldozing mechanism and earth-supporting mechanism 130, and the lower end of described putting soil tube 110 is open, and the center of the top wall of putting soil tube 110 offers top wall through-hole 111, and puts soil tube 110 The outside of the top wall is provided with a lifting portion and the top wall is provided with an upper wire through hole 113. The bulldozer mechanism includes a bulldozer plate 121 and a bulldozer rod 122 vertically arranged at the center of the bulldozer plate 121. The bulldozer mechanism is nested in the In the described soil-setting cylinder 110, a bulldozer plate 121 is fitted with a gap between the described soil-setting cylinder 110, and...

Embodiment 2

[0081] Such as Figure 4 As shown, an earth pressure cell embedding device includes an embedding cylinder, an embedding rod assembly and a hoisting rope 300, wherein:

[0082] Such as Figure 5 , the embedding tube includes a soil tube 110, a bulldozing mechanism and a soil support mechanism 130, the lower end of the soil tube 110 is open, and the top wall center of the soil tube 110 is provided with a top wall through hole 111, and the soil tube 110 The outside of the top wall is provided with a lifting portion and the top wall is provided with an upper wire through hole 113. The bulldozer mechanism includes a bulldozer plate 121 and a bulldozer rod 122 vertically arranged at the center of the bulldozer plate 121. The bulldozer mechanism is nested In the soil-setting cylinder 110, a bulldozing plate 121 is fitted with a gap between the soil-setting cylinder 110, and the bulldozing plate 121 is provided with a lower wire through hole 123 corresponding to the upper wire throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com