Tool installation mould for upside-down construction of multi-curve superimposed steel box girder and construction method thereof

A technology with multiple curves and construction methods, which is applied to bridges, bridge materials, bridge construction, etc., can solve the problems of low construction efficiency and the non-reusable use of traditional code boards, and achieve the effect of saving operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

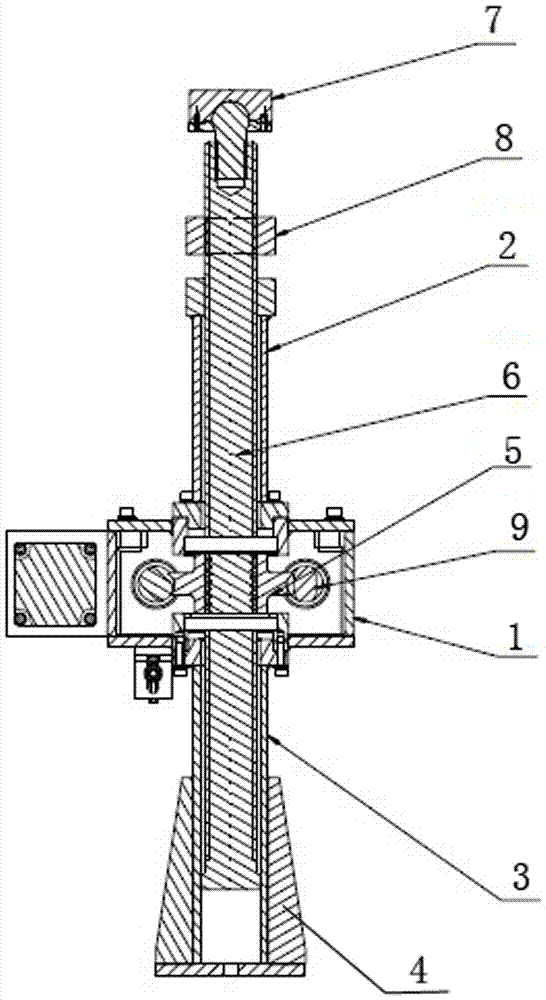

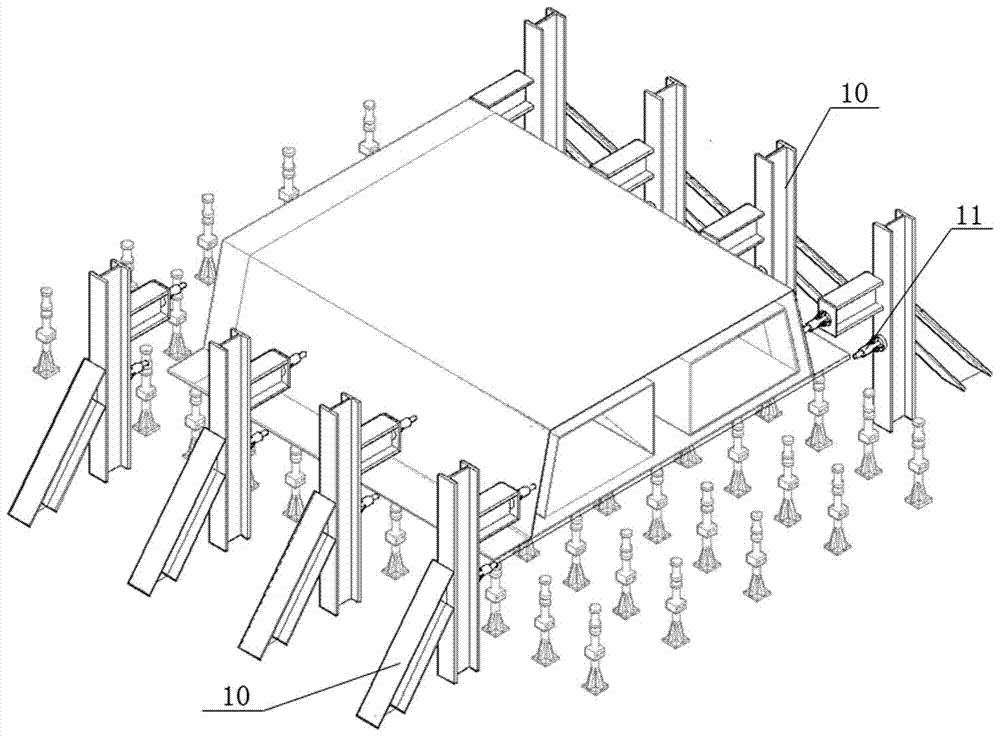

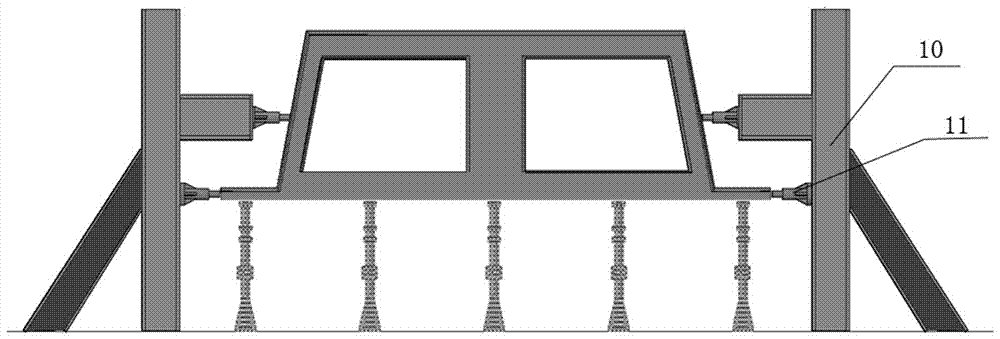

[0018] Multi-curve superimposed steel box girder inverted construction tooling, including box body 1, upper column 2 and lower column 3 respectively located above and below the box body are fixed on box body 1, and the lower end of lower column 3 is fixed on the base 4, the box is provided with a worm gear mechanism, the worm wheel 5 is provided with a screw 6 located in the upper column and the lower column body, the end of the worm 9 protrudes from the box 1 and is fixed with a rotating hand wheel, by rotating the hand Wheel turns worm screw 9 and rotates, and worm wheel 5 drives the nut on the leading screw to rotate, and then drives leading screw 6 to move in vertical direction, and the top of leading screw is provided with support head 7. The tire mold and the foundation are connected and fixed by anchor bolts, and the three-dimensional coordinate values of the screw are obtained by using CAD three-dimensional modeling and CAD loading program to unfold the sample, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com