Sharp-curve tunnel track-laying vehicle

A track-laying car and sharp-turning technology, applied in the directions of roads, tracks, laying tracks, etc., can solve the problems of manpower, material resources, length limitation, and large positioning deviation, and achieve the effect of avoiding manpower and time, convenient laying, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

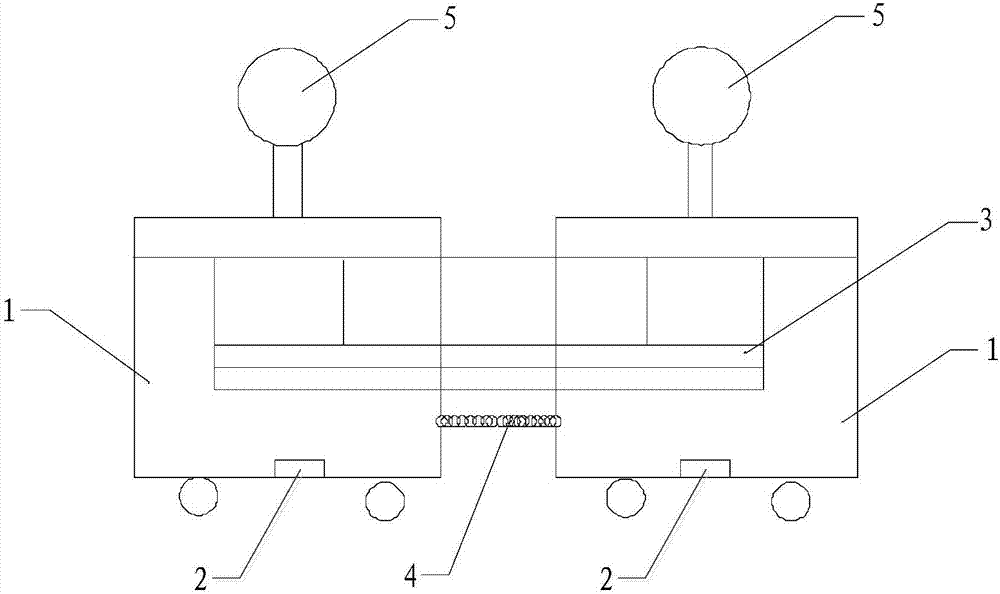

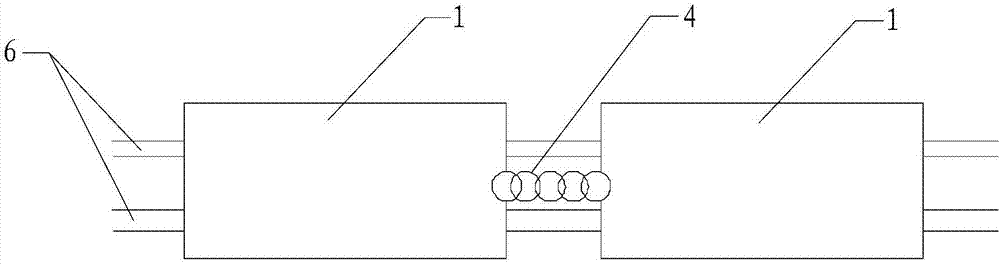

[0029] Such as figure 1 , 2 As shown, a sharp-turn tunnel track-laying car includes at least two car bodies 1, a driving device 2, and a rail-grabbing mechanism 3. Two adjacent car bodies 1 are connected by a flexible rotating pendulum 4, and each car body The body 1 is correspondingly provided with a driving device 2 for driving the vehicle body 1 to move, and the rail gripping mechanism 3 is provided on the vehicle body 1 for picking and placing the rail 6 . Two adjacent car bodies 1 of the product of the present invention are connected by a flexible rotating pendulum 4, which can realize arbitrary rotation between car bodies 1 and car bodies 1, and facilitate the laying of the track 6 when turning with a small r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com