Poplar pencil coating and preparation method thereof

A technology for pencils and coatings, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of poor waterproofing, mildew resistance, reduced service life of pencils, and difficulty in making pencils. glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

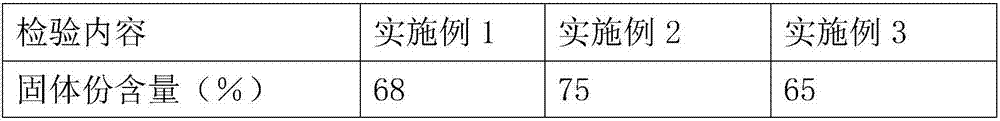

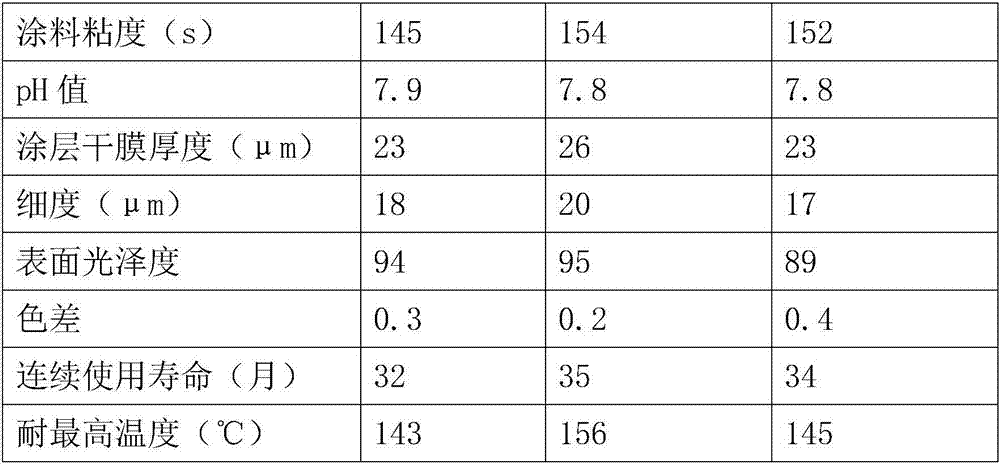

Embodiment 1

[0025] A poplar wood pencil paint is made of the following materials by weight,

[0026] 40 parts of acrylic resin, 5 parts of mica powder, 1 part of red gold powder, 2 parts of propylene glycol adipate, 0.2 parts of simethicone, 1 part of isocyanate, 2 parts of ferulic acid, 0.2 parts of pyrrolidone carboxylic acid, palmitic acid 1 part of ethyl ester, 5 parts of anti-aging agent, 2 parts of diethylene glycol butyl ether, 3 parts of VAE emulsion, 4 parts of milky white glue, 0.2 part of beeswax, 0.2 part of defoamer, 0.3 part of thickener, 0.1 part of petroleum coke powder , 10 parts of water-based white paste and 18 parts of deionized water.

[0027] A preparation method for poplar pencil paint, comprising the following preparation steps,

[0028] 1) Fully mix the above-mentioned materials except liquid materials, and then stir and disperse at 600 rpm for 10 minutes;

[0029] 2) Grind all the solid raw materials into powder, then add all the solid raw materials into the co...

Embodiment 2

[0037] A poplar wood pencil paint is made of the following materials by weight,

[0038] 45 parts of acrylate resin, 7 parts of mica powder, 2 parts of red gold powder, 3 parts of propylene glycol adipate, 0.5 parts of simethicone, 2 parts of isocyanate, 3 parts of ferulic acid, 0.3 parts of pyrrolidone carboxylic acid, palmitic acid 2 parts of ethyl ester, 6 parts of anti-aging agent, 3 parts of diethylene glycol butyl ether, 4 parts of VAE emulsion, 4.5 parts of milky white glue, 0.3 parts of beeswax, 0.25 parts of defoamer, 0.35 parts of thickener, 0.15 parts of petroleum coke powder , 15 parts of water-based white paste and 22 parts of deionized water.

[0039] A preparation method for poplar pencil paint, comprising the following preparation steps,

[0040] 1) Fully mix the above-mentioned materials except liquid materials, and then stir and disperse at 625 rpm for 15 minutes;

[0041] 2) Grind all the solid raw materials into powder, then add all the solid raw material...

Embodiment 3

[0049] A poplar wood pencil paint is made of the following materials by weight,

[0050] 50 parts of acrylate resin, 9 parts of mica powder, 3 parts of red gold powder, 4 parts of propylene glycol adipate, 0.8 parts of simethicone, 3 parts of isocyanate, 4 parts of ferulic acid, 0.4 parts of pyrrolidone carboxylic acid, palmitic acid 3 parts of ethyl ester, 8 parts of anti-aging agent, 4 parts of diethylene glycol butyl ether, 5 parts of VAE emulsion, 5 parts of milky white glue, 0.4 part of beeswax, 0.3 part of defoamer, 0.4 part of thickener, 0 petroleum coke powder. 2 parts, 20 parts of water-based white paste and 25 parts of deionized water.

[0051] A preparation method for poplar pencil paint, comprising the following preparation steps,

[0052] 1) Fully mix the above-mentioned materials except the liquid materials, and then stir and disperse at 650 rpm for 20 minutes;

[0053] 2) Grind all the solid raw materials into powder, then add all the solid raw materials into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com