Turnover device for packaging line

A packaging line and flipping device technology, applied in the field of packaging, can solve the problems of large footprint of the assembly line and limit the scope of application of the assembly line, so as to save the floor area, change the direction of product placement, and ensure the integrity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

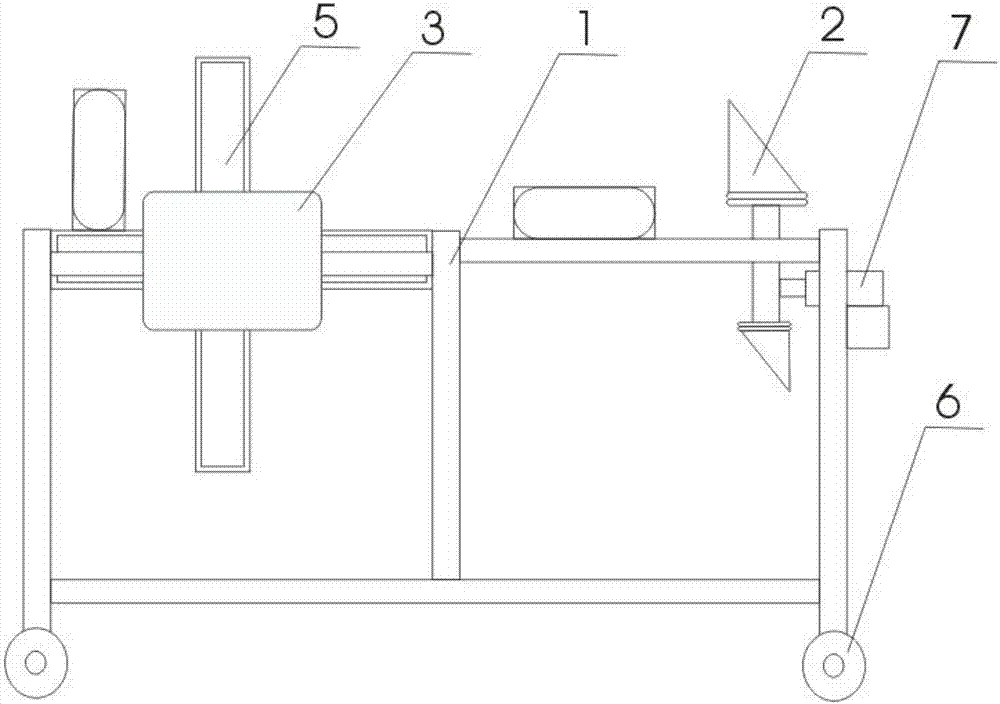

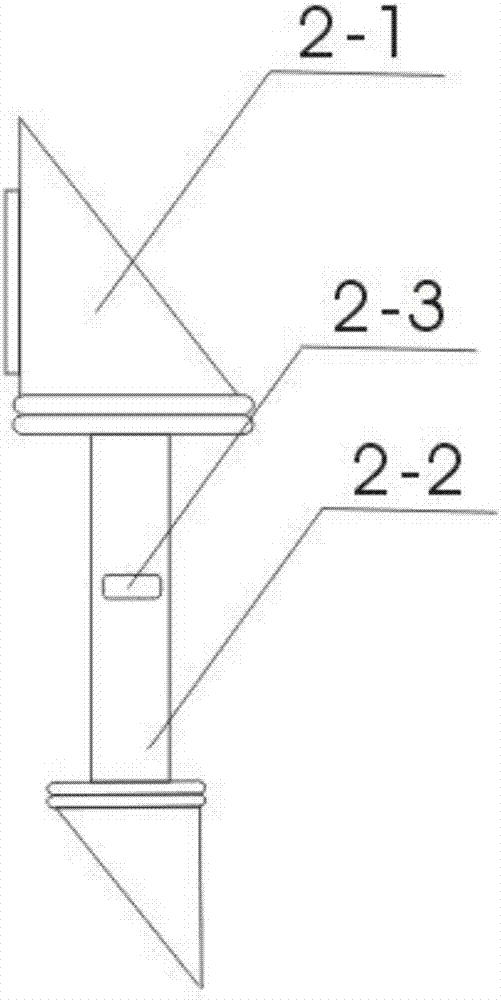

[0015] The present invention provides an overturning device 8 for a packaging assembly line 9, which includes a support 1, a material pushing structure 2, a motor 3, a rotating shaft 4, an overturning structure 5, a moving wheel 6, and a cylinder 7. A moving wheel 6 is installed on the lower side of the support 1, and the support 1. The motor 3 and the cylinder 7 are installed on the side. The output shaft of the motor 3 is connected to the shaft 4. One side of the shaft 4 is connected to the output shaft of the motor 3. The other side of the shaft 4 is connected to the bracket 1. The shaft 4 is a rotating structure. The upper side of the shaft 4 An overturning structure 5 is installed, and the overturning structure 5 is located on one side of the upper part of the bracket 1, and the other side of the upper part of the bracket 1 is equipped with a pushing structure 2, which is connected with the cylinder 7, and the pushing structure 2 is installed on the moving track, and the mo...

Embodiment 2

[0017] During use, the present invention is installed between two conveying devices, is used for changing the product conveying direction, and product is transferred to the support 1 of the present invention by conveyer belt, when product is conveyed before the pushing structure 2 on support 1 of the present invention , the sensing device on the pusher structure 2 receives the information and sends it to the controller, the controller sends the information to the cylinder 7, the cylinder 7 moves and drives the pusher structure 2 to move, and the pusher structure 2 pushes the product to the turning point On the structure 5, the induction device on the turning structure 5 receives the signal, and transmits the signal to the controller, and the controller transmits the information to the motor 3, and the motor 3 moves and drives the turning structure 5 to rotate, and the turning structure 5 drives the product and It rotates to change the direction of the product. After the rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com