a 3d printer

A 3D printer and printing device technology, applied in the field of 3D printing, can solve the problems of not meeting the existing needs, affecting normal printing, and unfixed mold trays, etc., and achieve the effect of improving printing efficiency, printing accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

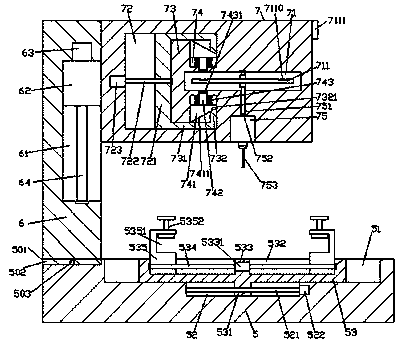

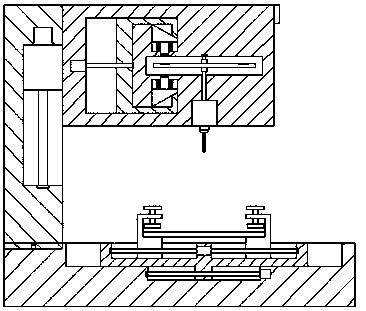

[0023] Such as Figure 1-Figure 5As shown, a 3D printer of the present invention includes a base 5 and a printing device 7 arranged above the top of the base 5, a pillar 6 is arranged on the top left side of the base 5, and a pillar 6 is arranged on the top left side of the base 5. There are first sliding grooves 51 arranged on the same front and back, and a second sliding groove 52 is provided at the middle end of the inner bottom surface of each of the first sliding grooves 51, and the left and right elongating devices are arranged in the second sliding grooves 52. The first screw 521, the first sliding block 53 is slidably connected to the first sliding groove 51, the printing device 7 is provided with a sliding cavity 72, and the right side of the sliding cavity 72 is provided inside There is a convex end 73, which is provided with a locking chamber 71 elongated toward the right side inside the convex end 73, and a printing driving device 75 is fixedly arranged in the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com