Preparation method and application of partially sulfurized metal-organic framework composite material

A metal-organic framework and composite material technology, which is applied to the preparation of partially sulfided metal-organic framework composite materials and its application fields, can solve the problems of high price, low reserves, and restrict wide application, and achieves low equipment requirements, simple process, and distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 (precursor Cu-MOFs preparation)

[0043] (1) Dissolve 20mg of copper nitrate, 10mg of tetracarboxylic acid organic ligand in 2mL of DMF (N,N-dimethylformamide), 1mL of 1,4 dioxane, and 1mL of deionized water. The solution was sonicated at room temperature for 30 min to obtain mixed liquid A.

[0044] (2) Put the above mixed liquid A in a 20 ml glass vial, then place it in a constant temperature drying oven at 80°C for 12 hours, then transfer it to a constant temperature drying oven at 60°C for 23 hours, and cool it down to room temperature naturally to obtain White powder crystals, washed three times with absolute ethanol to obtain product B as a mixed liquid.

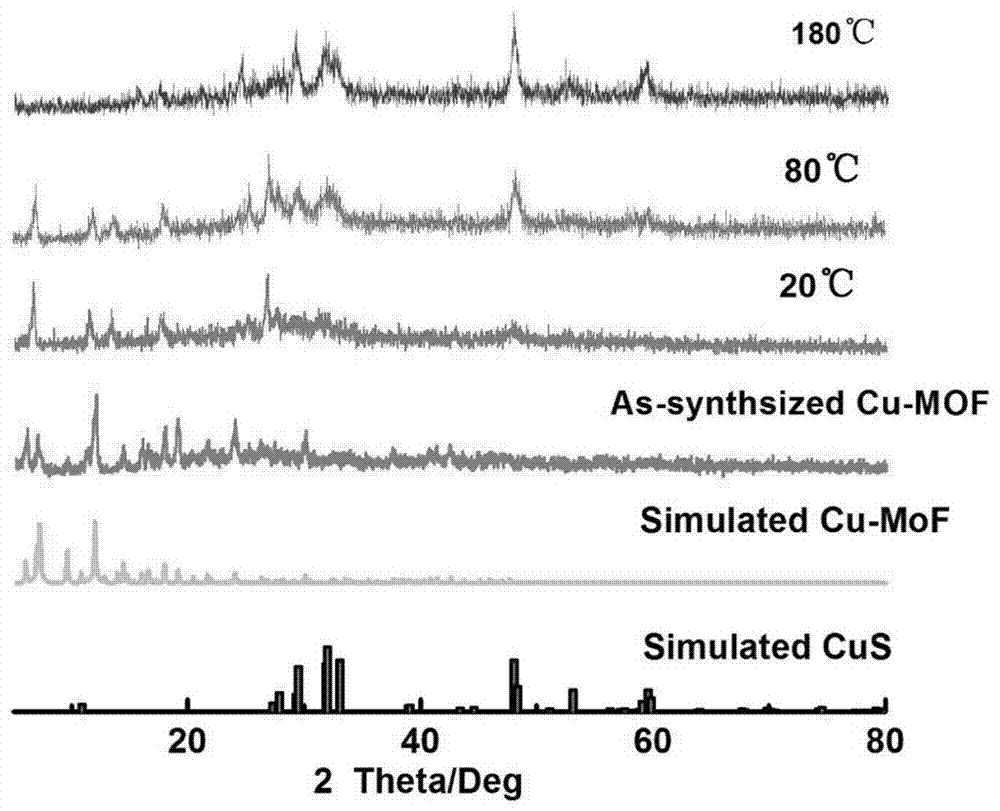

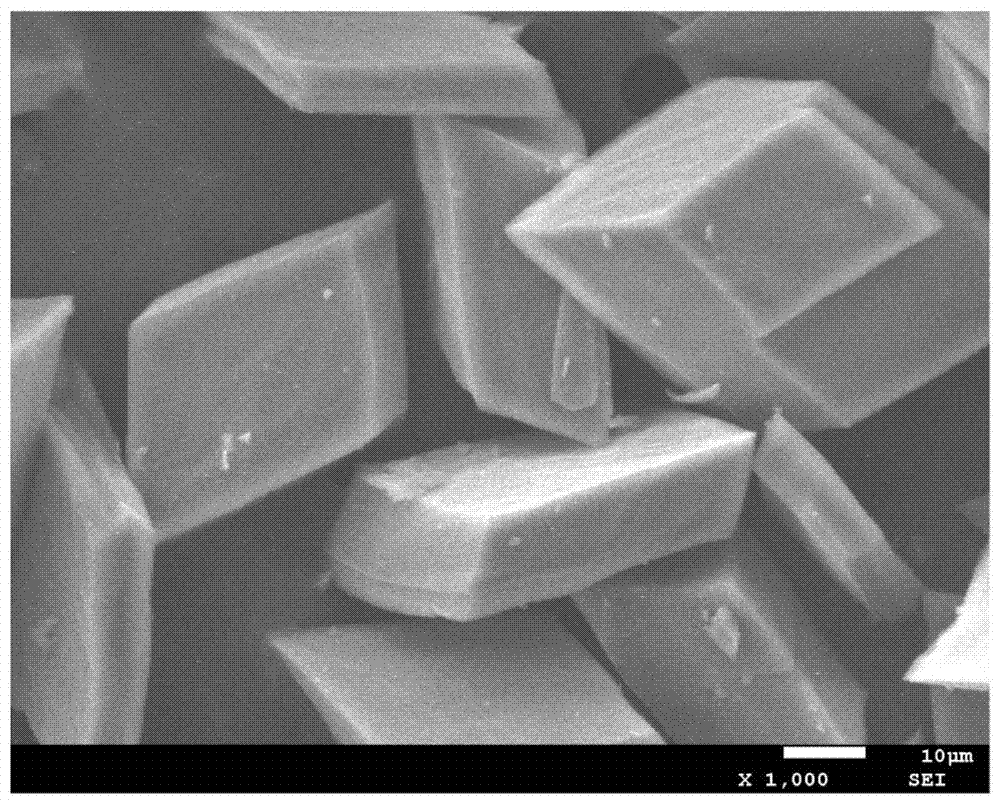

[0045] (3) Soak the mixed liquid B obtained after the above centrifugation in ethanol for 3 days, replace the ethanol solution every 12 hours, and dry it in a vacuum oven at 60°C for 24 hours after 3 days to obtain activated Cu-MOFs samples, Cu-MOFs samples The comparison chart of X-ray diffraction p...

Embodiment 2

[0046] Example 2 (preparation of vulcanized 10% metal-organic framework composite material)

[0047] The ethanol solutions of 50 mg of Cu-MOFs material obtained in Example 1 and 75 mg of thioacetamide were left to stand at 20° C. for two hours respectively. After the mixed liquid product obtained above is filtered, it is washed three times with distilled water and absolute ethanol in sequence, and the obtained product is vacuum-dried at 20 ° C ~ 100 ° C for 4-6 hours to obtain a metal-organic framework with 10% vulcanization Composite material B.

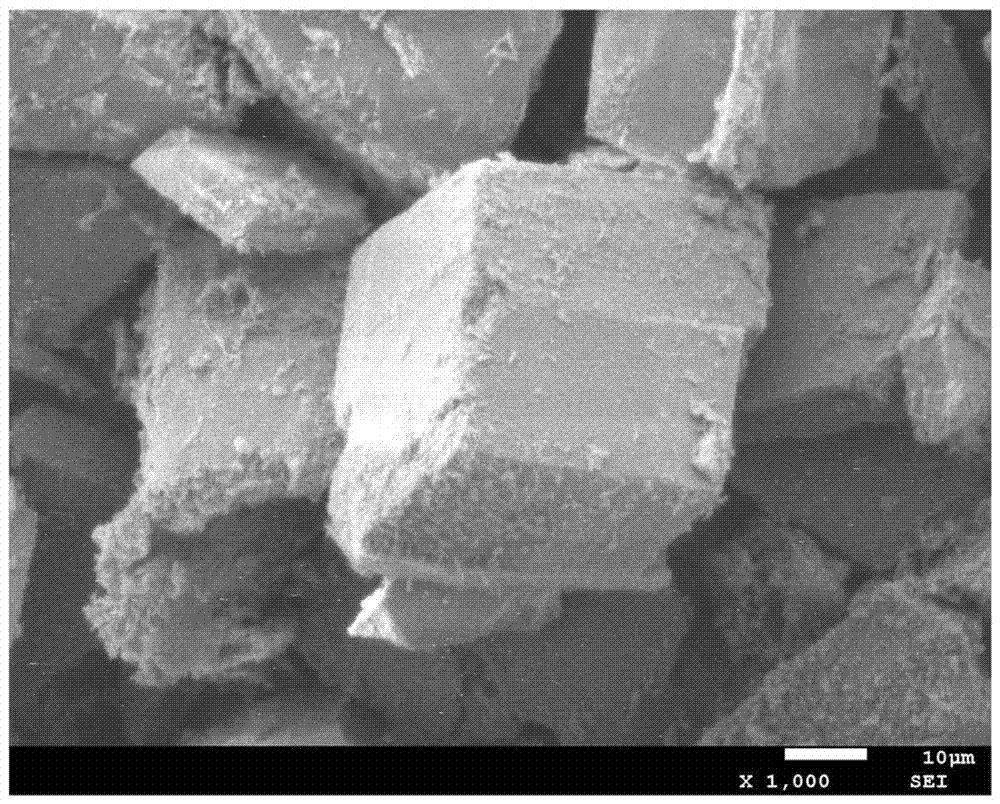

[0048] The CuS@Cu-MOFs samples prepared above were analyzed by XRD, and the results are shown in figure 1 of 20°C by figure 1 It can be seen that all diffraction peaks (002), (004), (100), (101), (102), (103), (006), (104) (105), (106), (008), (107 ), (110), (112), (108), (114), (0010), (201), (202), (109), (203), (116), (204), (205), (1010) (206), (118), (0012), (1011), (207), (208), (1012) (1011) (210), (211), (212), (209), ( ...

Embodiment 3

[0054] Example 3 (preparation of vulcanized 50% metal-organic framework composite material)

[0055] The ethanol solutions of 50 mg of Cu-MOFs material obtained in Example 1 and 75 mg of thioacetamide were left to stand at 80° C. for two hours respectively. After the mixed liquid product obtained above is filtered, it is washed three times with distilled water and absolute ethanol in sequence, and the obtained product is vacuum-dried at 20°C ~ 100°C for 4-6 hours to obtain a metal-organic framework with 50% vulcanization Composite material C.

[0056] The CuS@Cu-MOFs samples prepared above were analyzed by XRD, and the results are shown in figure 1 of 80°C by figure 1 It can be seen that all diffraction peaks (002), (004), (100), (101), (102), (103), (006), (104) (105), (106), (008), (107 ), (110), (112), (108), (114), (0010), (201), (202), (109), (203), (116), (204), (205), (1010) (206), (118), (0012), (1011), (207), (208), (1012) (1011) (210), (211), (212), (209), ( 213...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com