Insertion device for motor stator slot insulation paper

A technology of motor stator and insertion equipment, which is applied in the direction of laying solid insulation, etc., can solve the problems of affecting the fitting accuracy of stator slots, affecting the arrangement of coil windings, affecting work efficiency, etc., and achieves the goal of improving plasticity, reducing errors, and improving overall performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

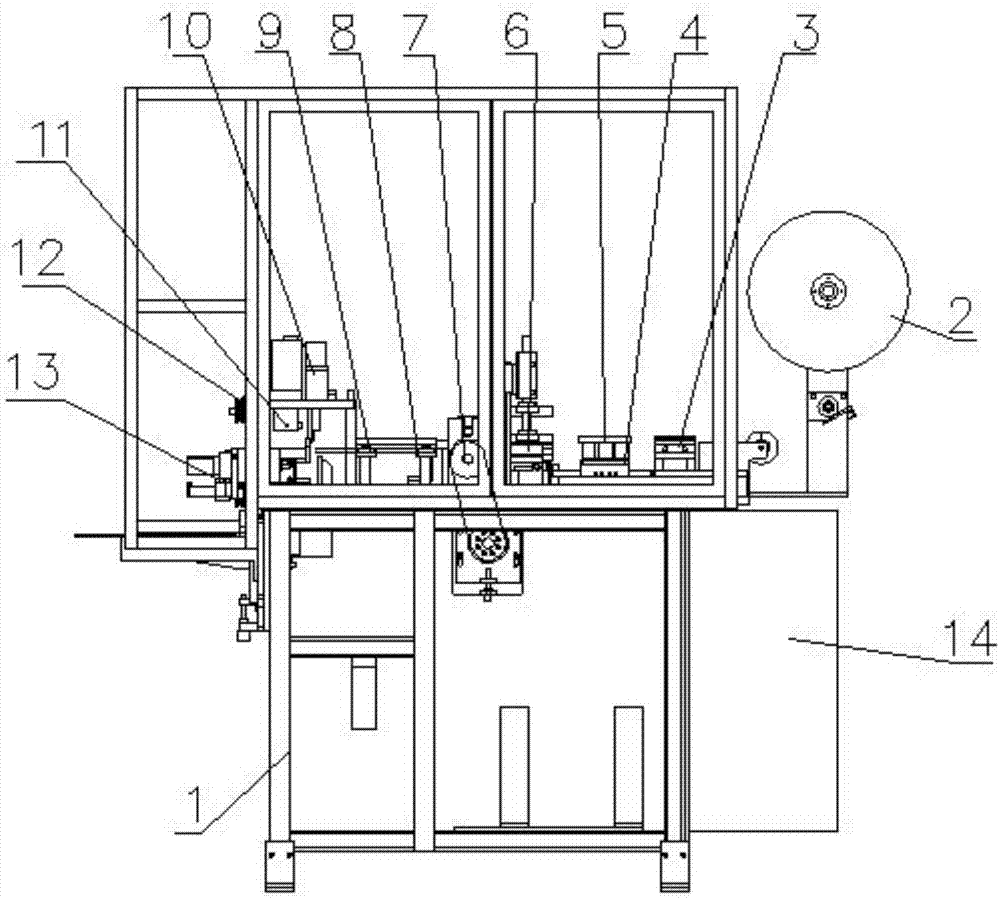

[0025] like Figure 1-Figure 7 As shown, the present invention schematically shows a device for inserting insulating paper in a stator slot of a motor.

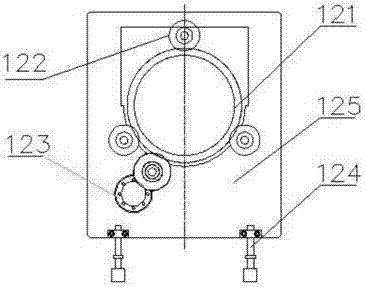

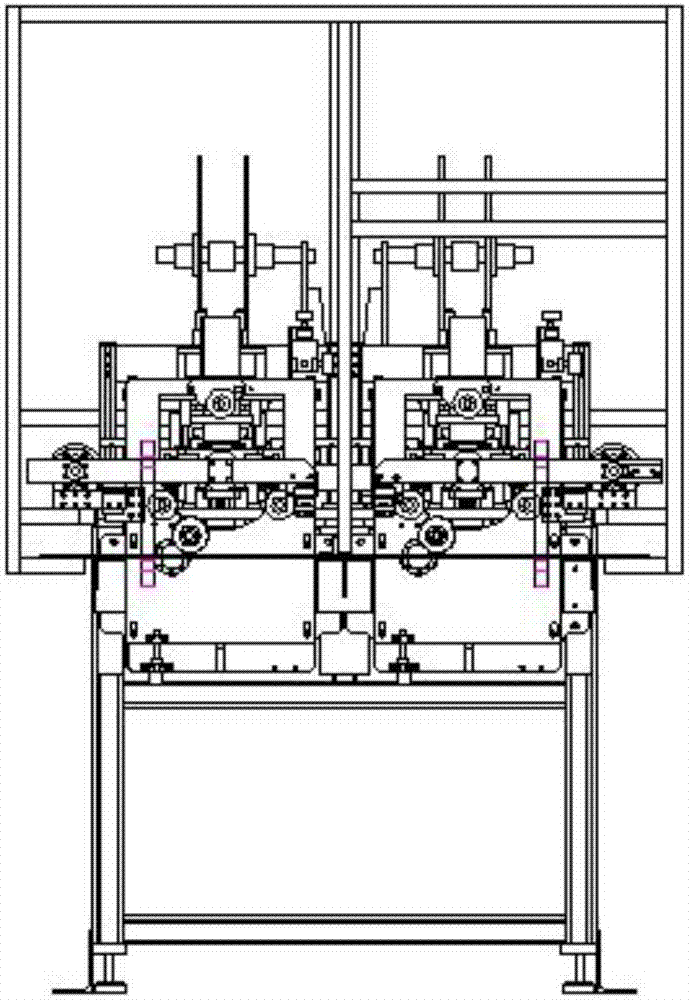

[0026] The invention discloses a device for inserting insulating paper in a stator slot of a motor, such as figure 1 As shown, it includes frame 1, unwinding device 2, heating device 3, creasing device 4, preforming device 5, first forming device 6, paper feeding device 7, angle cutting device 8, paper inserting device 9, cutting device 10. The second forming device 11, the indexing device 12, the stator mounting device 13 and the electrical cabinet assembly 14; such as figure 2 As shown, the equipment is a dual-station equipment, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com