Inductive sensor calibration method and device for three-axis laser interferometer measurement

A technology of laser interferometer and inductance sensor, which is applied in the field of precision measurement to achieve the effect of ensuring calibration accuracy, high precision and eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

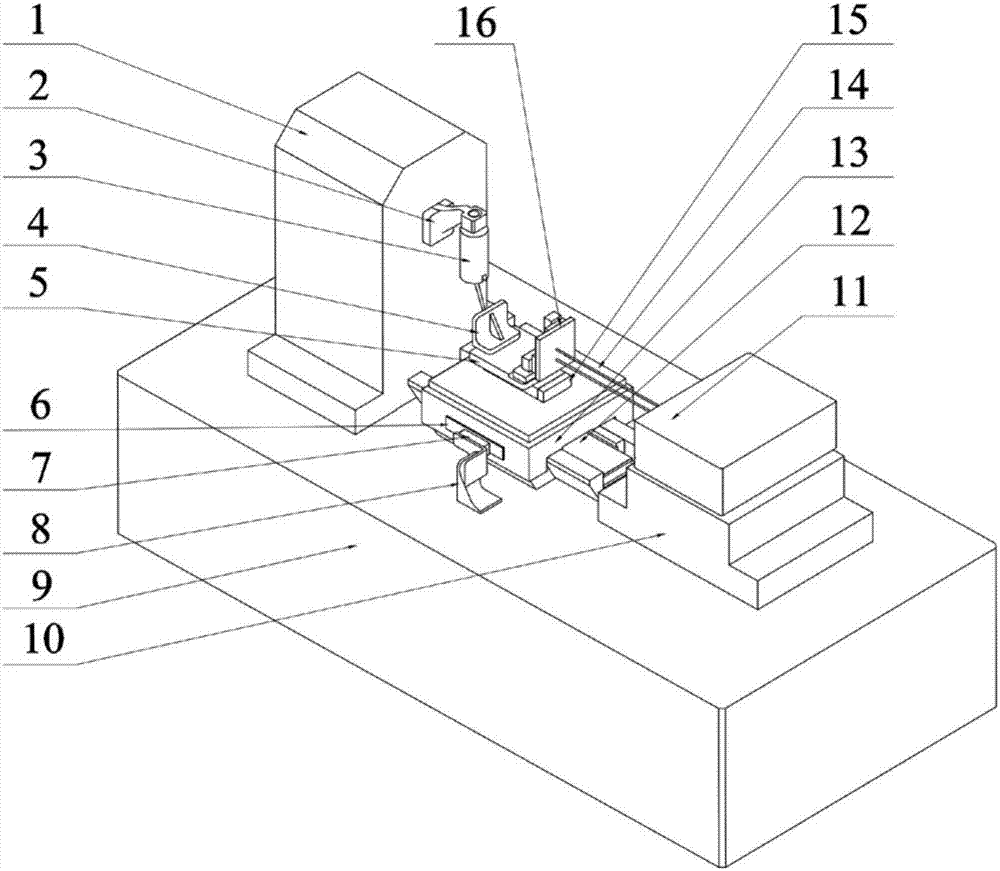

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

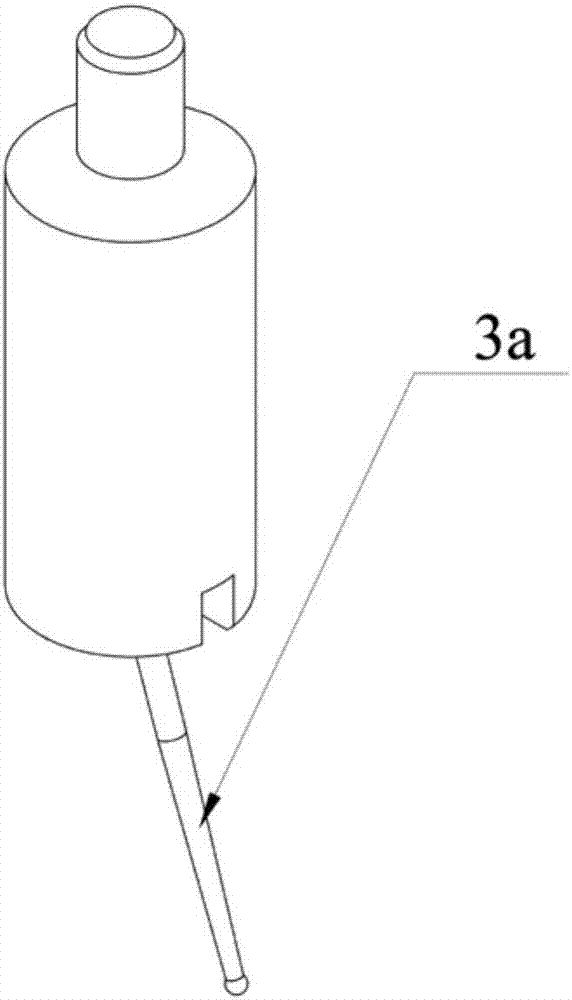

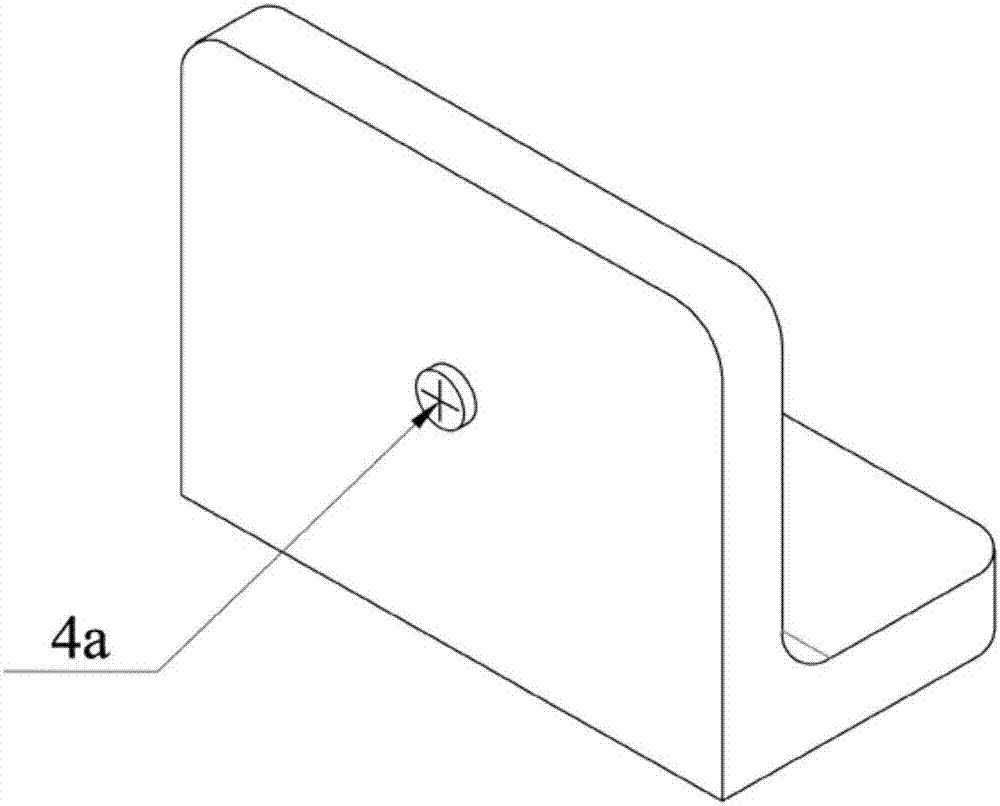

[0021] A method and device for calibrating an inductance sensor measured by a three-optical axis laser interferometer. The method and device are as follows: the whole device is mainly divided into three parts: a displacement sensor to be calibrated, a displacement transmission mechanism and a displacement reference instrument. The whole device is placed on a vibration isolation platform and placed in a constant temperature environment. The calibrated displacement sensor adopts the inductive displacement sensor 3, and the inductive displacement sensor 3 is clamped and fixed by the sensor clamping arm 2, and the position of the inductive displacement sensor 3 is adjusted to ensure that the movement axis of the measuring needle 3a of the inductive displacement sensor 3 is in line with the three-axis laser The optical axes of the light beams 11b of the interferometer 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com