A kind of wave-absorbing material of carbon fiber surface coated magnetic ferrite nano carbon tube and its preparation method and application

A magnetic ferrite and surface coating technology, applied in the field of wave-absorbing materials, can solve problems such as high dielectric constant and poor impedance matching, achieve good wave-absorbing performance, simple preparation method, rich design and scientific preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

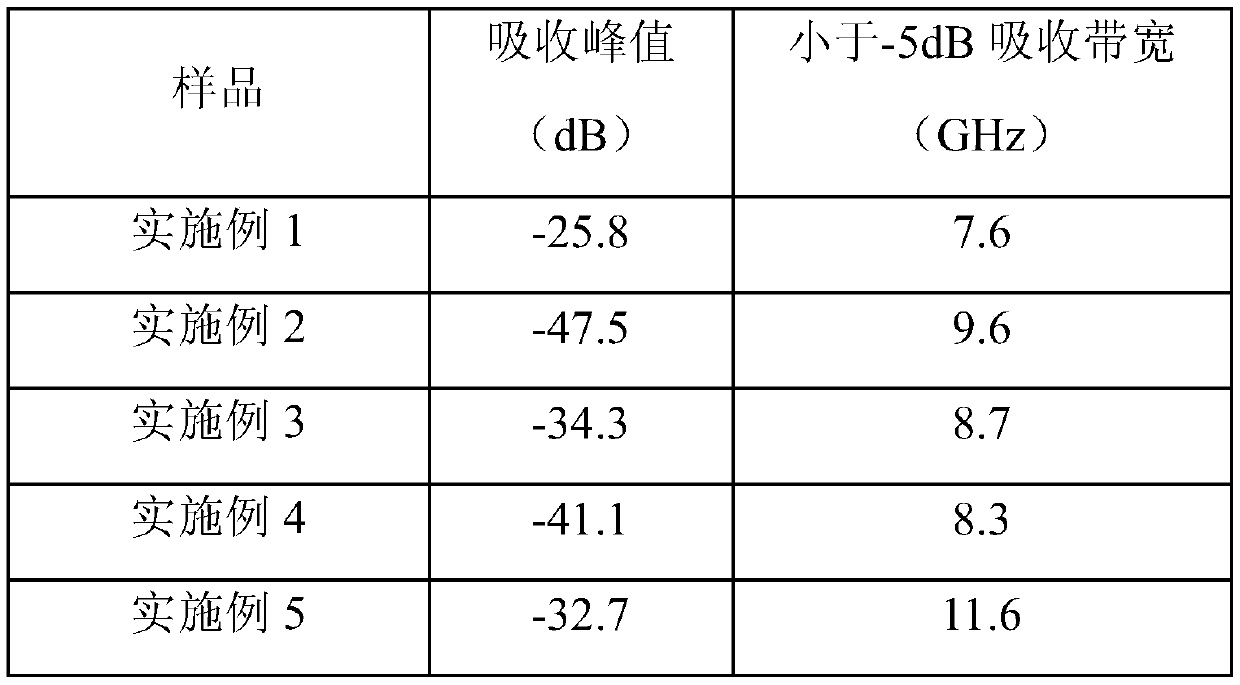

Embodiment 1

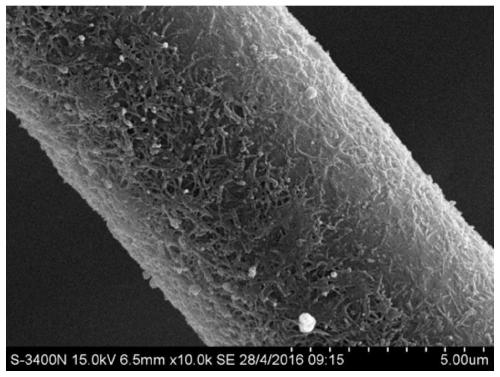

[0038] Example 1 Preparation of microwave-absorbing material with carbon fiber surface-coated ferric oxide carbon nanotubes

[0039] (1) Magnetic ferroferric oxide (Fe 3 o 4 ) Preparation of nanoparticles: first add 100 mL of deionized water to a 250 mL dry three-necked round-bottomed flask, then add 1.0 g (3.6 mmol) of FeCl under nitrogen protection 3 ·6H 2 O and 0.4g (2.0mmol) FeCl 2 4H 2 O, ultrasonically disperse until the solid is completely dissolved, then add 50mL of 0.4mol / L NaOH aqueous solution drop by drop to the above reaction solution; after the drop, add 0.2g sodium oleate and react for 3.0 hours; The black solid product was washed several times with deionized water and ethanol, respectively. After drying in an ordinary oven at 80°C for 2 hours and in a vacuum oven at 50°C for 12 hours, magnetic ferric oxide nanoparticles are obtained, and the size of the particles is 5-20nm.

[0040] (2) Preparation of ferric iron tetroxide polyphosphazene nanotubes coated...

Embodiment 2

[0043] Example 2 Preparation of microwave-absorbing material of carbon fiber surface-coated ferric oxide carbon nanotubes

[0044] (1) Magnetic ferroferric oxide (Fe 3 o 4 ) Preparation of nanoparticles: see step (1) of Example 1 for details.

[0045] (2) Preparation of ferric iron tetroxide polyphosphazene nanotubes coated with carbon fiber surface: add 0.2 gram of magnetic ferric ferric oxide (Fe 3 o 4 ) nanoparticles, then add 130mL anhydrous tetrahydrofuran, ultrasonically disperse for 1.0 hour; then place 1.2 grams of carbon fiber bundles in the middle of the square frame of the polytetrafluoroethylene container (outer frame 8cm*8cm, inner frame 7cm*7cm) and immerse the above glassware In, then add 1.0 g (2.88 mmol) hexachlorocyclotriphosphazene and 2.16 g (8.64 mmol) 4,4'-dihydroxydiphenyl sulfone, ultrasonic 0.5 hour to make hexachlorocyclotriphosphazene and 4,4'- Dihydroxydiphenyl sulfone is completely dissolved, then add 3.5mL of triethylamine, take out the carbon...

Embodiment 3

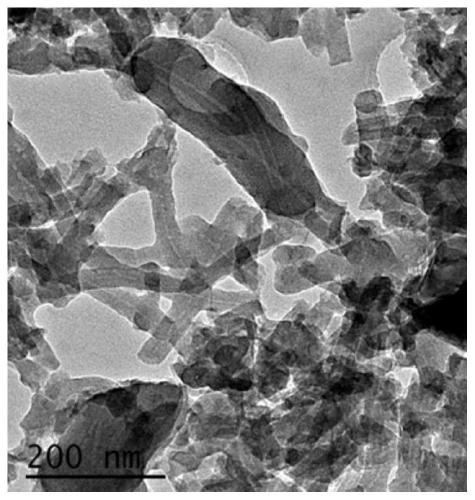

[0048] Example 3 carbon fiber surface coating zinc ferrite (ZnFe 2 o 4 ) Preparation of microwave-absorbing materials for carbon nanotubes

[0049] (1) Magnetic zinc ferrite (ZnFe 2 o 4 ) Preparation of nanoparticles: first add 60mL of deionized water to a 150mL dry three-neck round-bottomed flask, then add 1.19 grams (4.0mmol) of Zn(NO 3 ) 2 ·6H 2 O and 2.33 g (8.0 mmol) Fe(NO 3 ) 3 9H 2 0, stirred until completely dissolved; then added 3.78 grams (18.0 mmol) of citric acid complexing agent, heated to 50° C. under stirring, slowly added dropwise ammonia to the above reaction solution to adjust the pH of the solution to about 3.0, so that the complexing agent was completely Dissolve; then add 7.67g of acrylamide to the above reaction solution, stir for half an hour, add 1.0g of glucose, stir and heat up to 80°C, and form a wet gel after 4 hours of reaction; put the wet gel into a common oven at 120°C to dry After 12 hours, dry in a vacuum drying oven at 80°C for 12 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| absorption frequency | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com