Vehicle assembly method

A technology of automobiles and assembly parts, applied in the field of automobile manufacturing, can solve the problems of personal injury and low efficiency of assembly personnel, and achieve the effect of ensuring safety, reducing quantity and realizing automatic circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

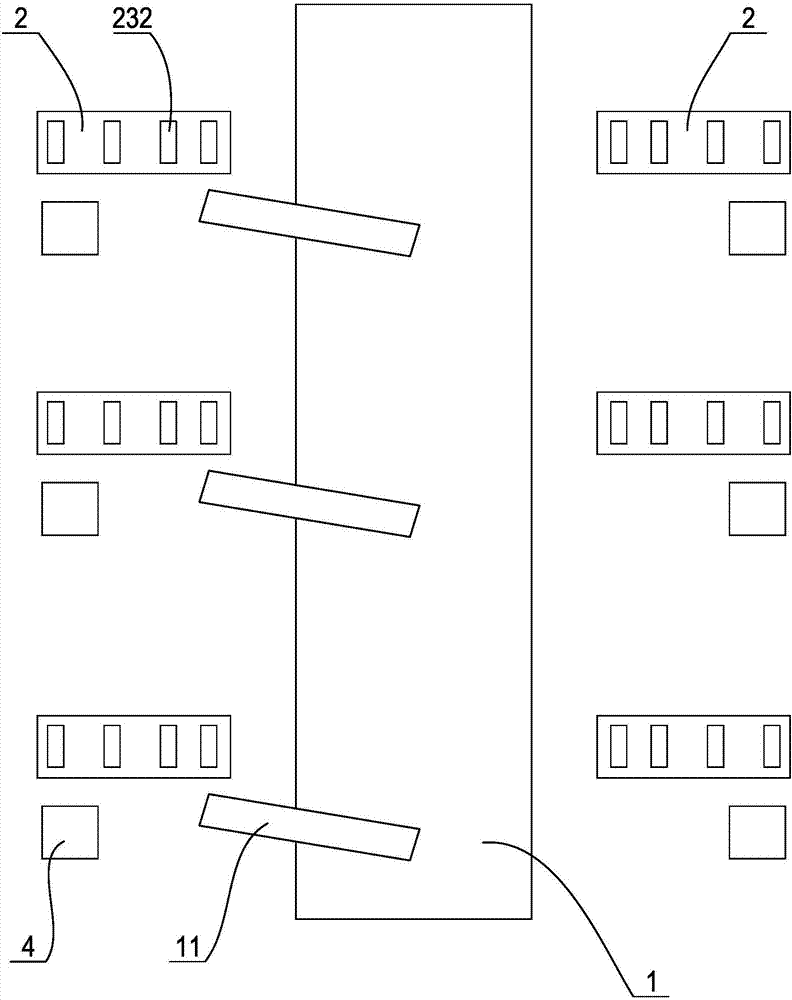

[0038] Such as figure 1 Shown, a kind of method for automobile assembly, comprises the steps:

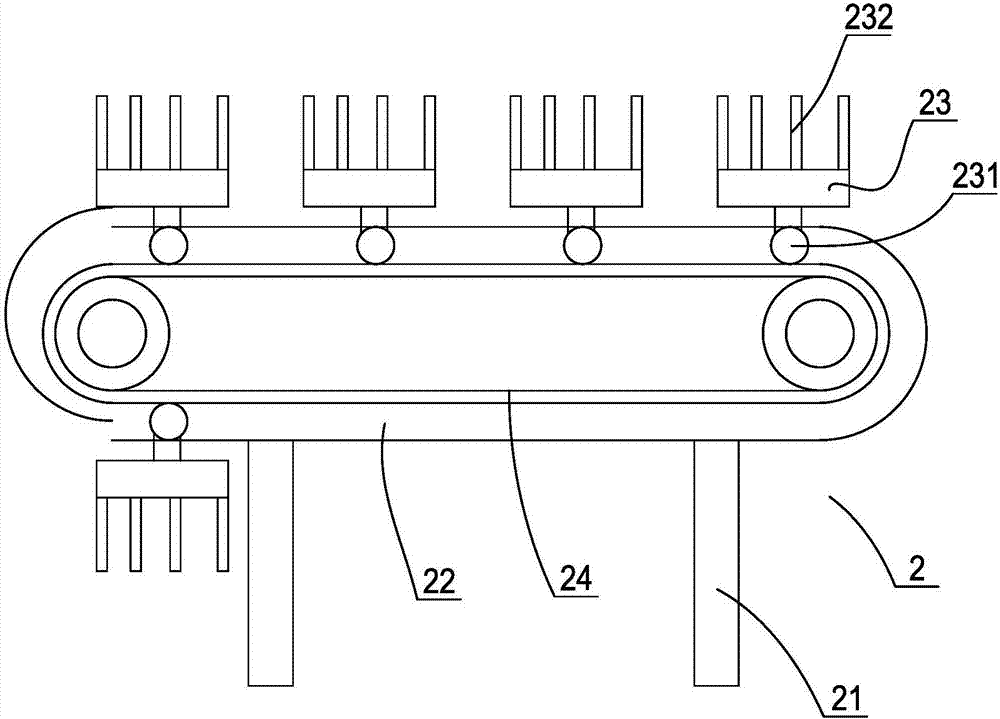

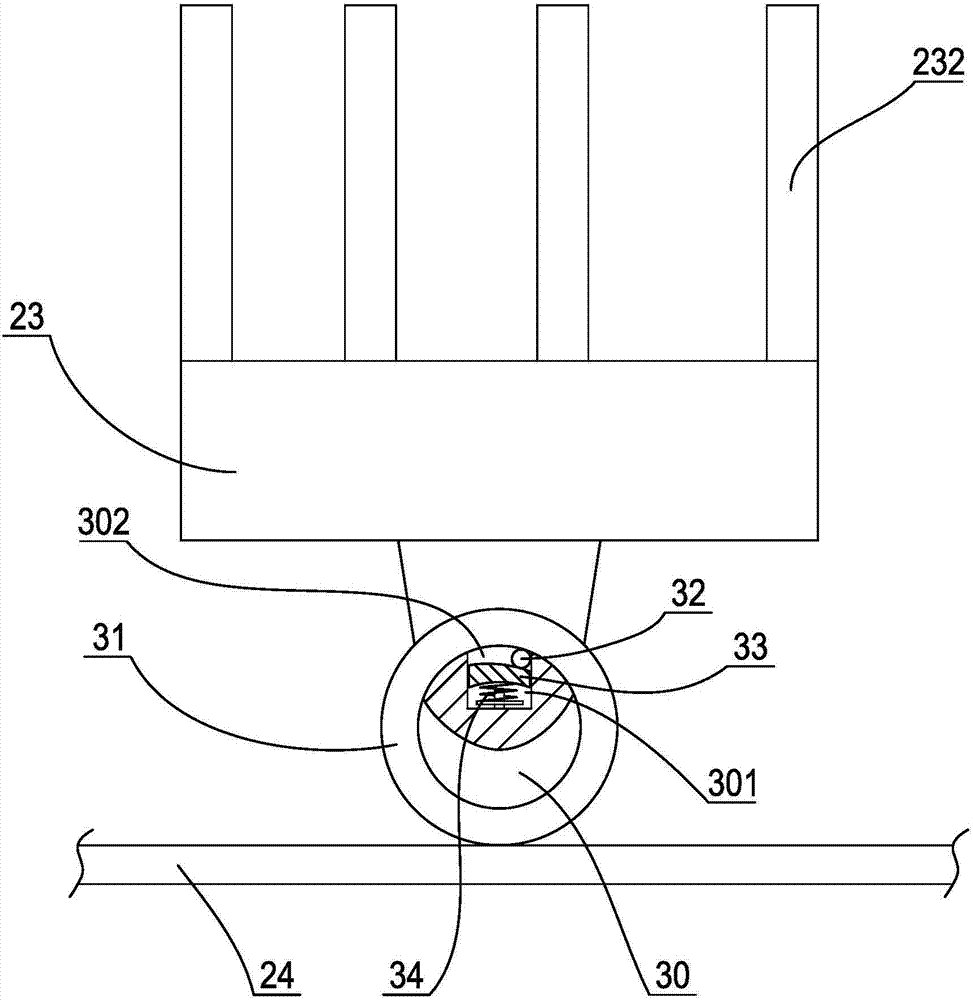

[0039] a. The annular conveying line 2 is arranged respectively at the positions corresponding to each process on the side of the main production line 1 with the manipulator 11 for assembling, specifically, as figure 2 As shown, the annular conveying line 2 comprises a frame 21, on the frame 21, two oblong annular tracks 22 are arranged side by side, and some movable trays 23 are set between the two annular tracks 22, and the left and right sides of the tray 23 The rollers 231 rollingly connected in the ring track 22 of the corresponding side are respectively provided on the sides, the positioning device 232 for positioning the assembled parts is provided on the tray 23, and two oblong drive chains 24 on the left and right are also provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com