Multi-terminal compression system and compression method

A terminal crimping and terminal technology, which is applied in the direction of connection, electrical components, circuits, etc., can solve the problems of insufficient structural layout, inconvenient maintenance, and large space occupation, so as to facilitate follow-up maintenance, simple structure, and use of reduced space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

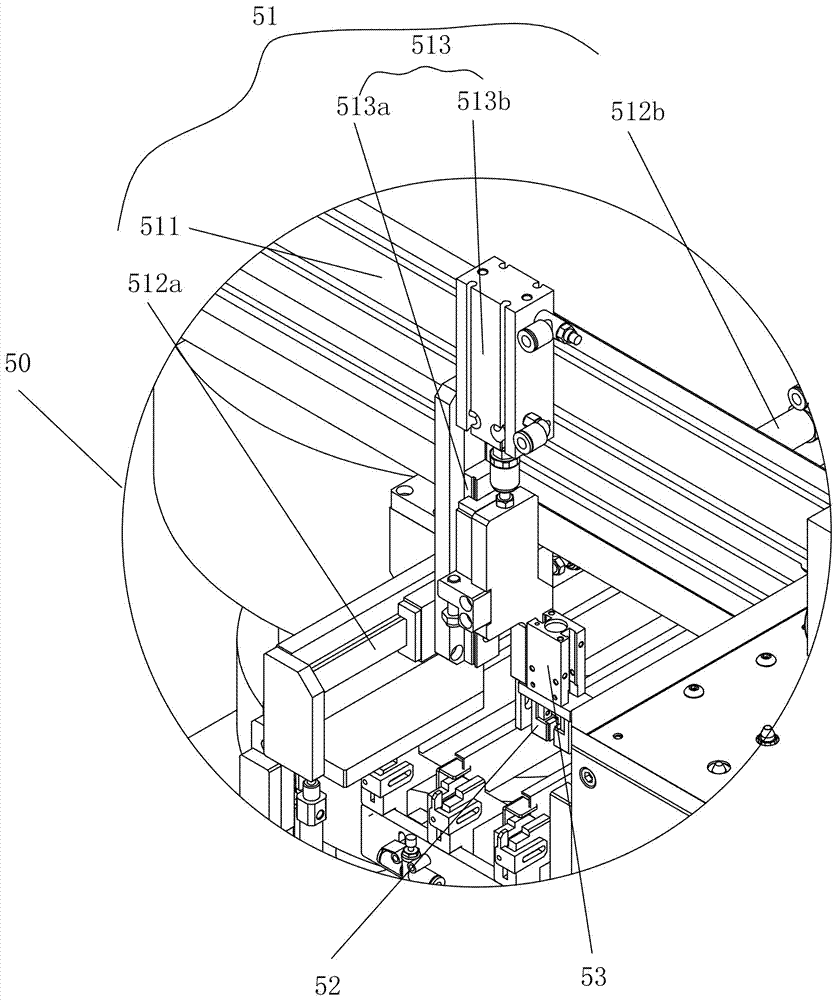

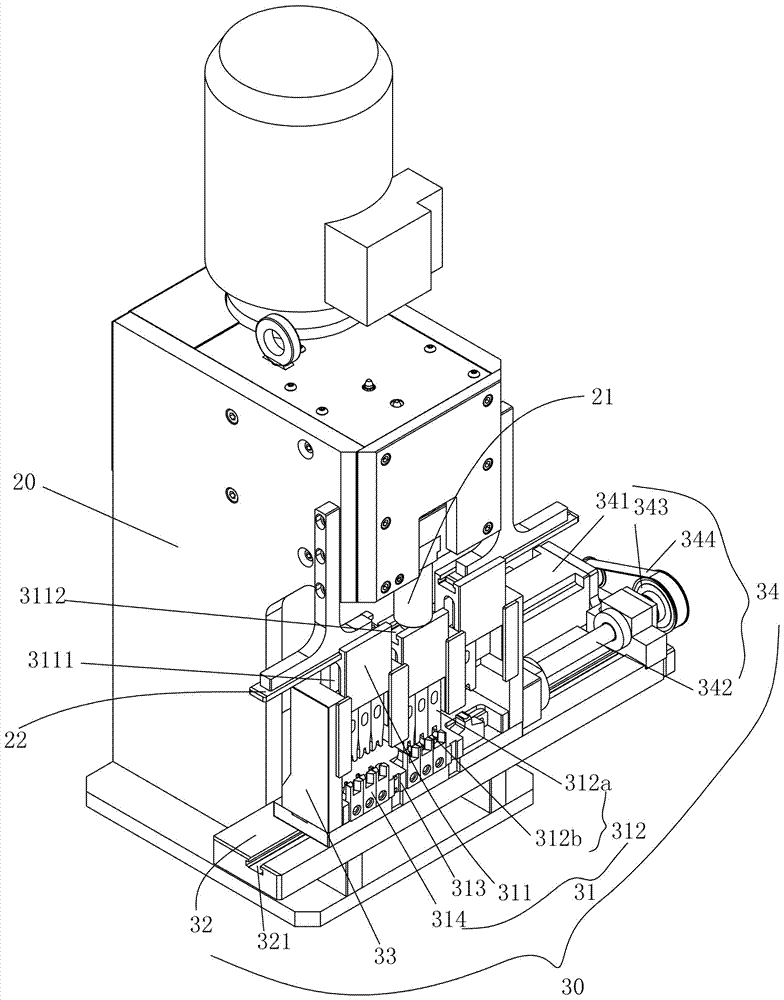

[0046] Such as figure 1 As shown, a variety of terminal crimping systems include a workbench 10, a terminal machine 20, a compound crimping mold 30, a plurality of discharge mechanisms 40 corresponding to various terminals, a grabbing mechanism 50, a threading mechanism 60, and a parallel mechanism 70. Auxiliary mechanism 80 and controller (the controller of the present invention is an existing programmable control system, which will not be described in detail here, and is not expressed in each figure). Controllers are used to control the operation of various terminal crimping systems. The terminal machine 20 is installed at the front end of the workbench 10 ; the multiple crimping die 30 is installed at the crimping die of the terminal machine 20 . Terminals In this embodiment, loose grain terminals are used. A plurality of discharge mechanisms 40 include a vibrating plate 41, a feeding track 42 and a straight vibrator (not shown in the figure) in this embodiment, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com