Prefabricated beam transverse movement and vertical falling device and beam falling method

A prefabricated girder lateral movement, vertical drop technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as erection of public bridge erecting machines in place, difficulty in ensuring the stability of beams, and inability to use hoisting equipment. It achieves the effects of fewer auxiliary personnel, avoiding uneasy control and easy falling, and simple installation and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

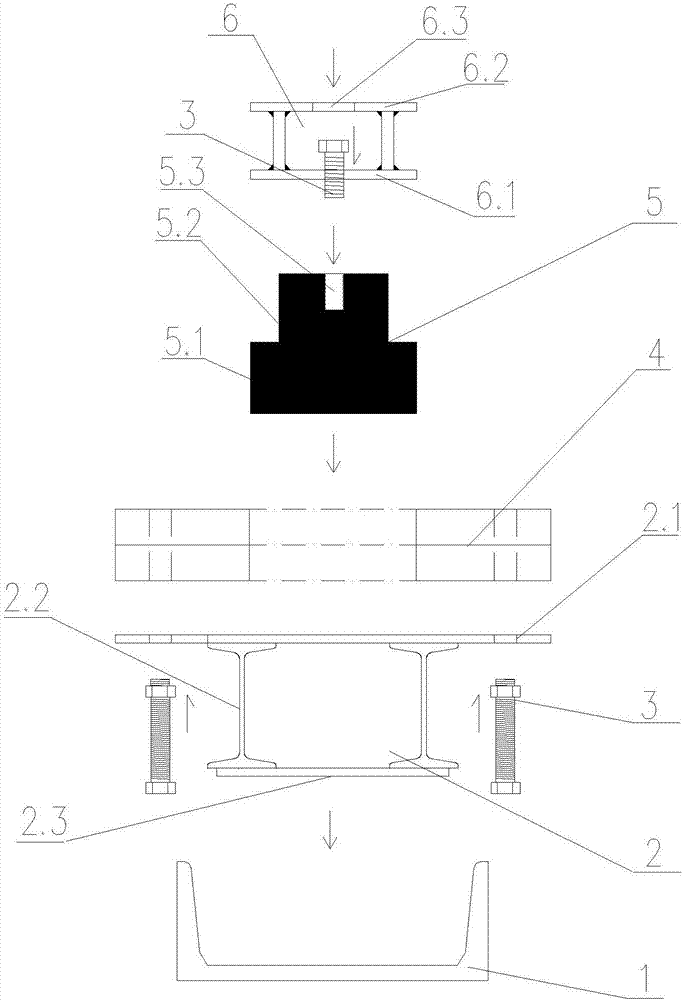

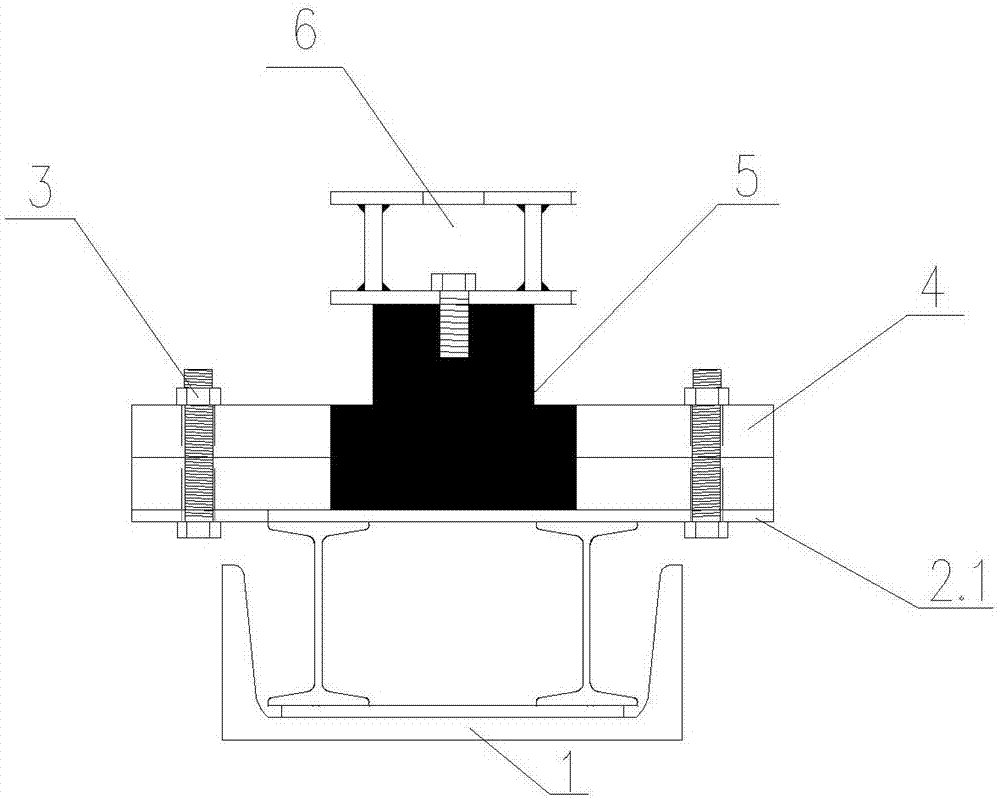

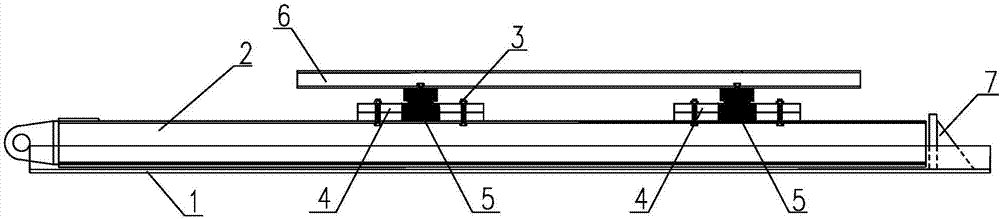

[0025] see Figure 1-Figure 3 , The device of the present invention includes a slide rail 1 and a slide beam 2, the slide rail 1 is placed on the cover beams on both sides of the prefabricated beam, and the slide beam 2 is placed in the slide rail 1. The key technology is to use high-strength bolts 3 on the sliding beam 2 to fix the vertical drop beam hydraulic jack slot 4 to ensure the stability of the prefabricated beam during the translation process, and to fix the thin-walled jack 5 on the vertical drop beam hydraulic jack slot 4. 5. Fix the prefabricated beam bottom support 6 for placing the prefabricated beam.

[0026] A limit baffle 7 is set at the end of the slide rail 1, which acts as a limit during the movement of the sliding beam 2 to ensure construction safety.

[0027] The sliding crossbeam 2 is welded with a bearing plate 2.1 at the upper end of two I-beams 2.2, and a sliding plate 2.3 at the lower end.

[0028] The prefabricated beam bottom bracket 6 is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com