A raw coal conveying device

A conveying device and raw coal technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of occupying plant space, increasing equipment, increasing equipment capital investment, etc., to achieve stable operation, reduce friction, increase The effect of sieving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the invention will be further described below in conjunction with the accompanying drawings.

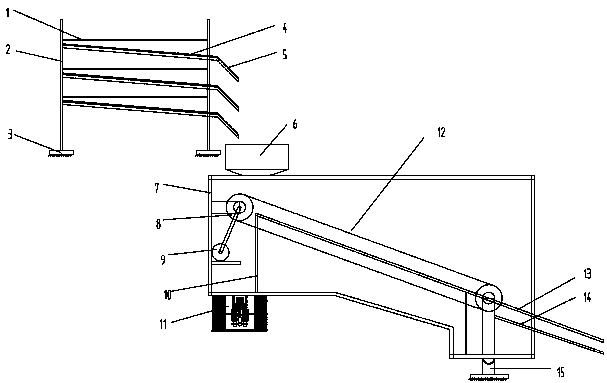

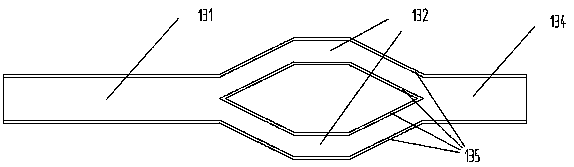

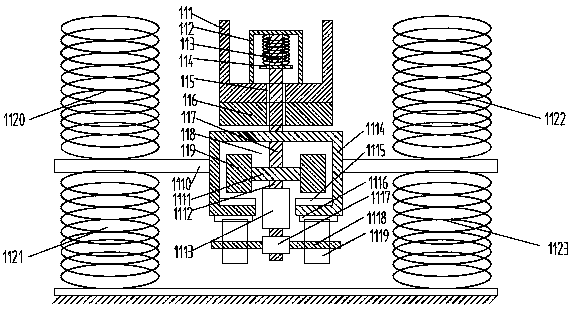

[0013] Such as figure 1 A raw coal conveying device shown includes a debris screen 1, a support frame 2, a base 3, a slideway groove 4, a guide blanking groove 5, a receiving hopper 6, a material distribution box 7, a pulley 8, a motor 9, and small-sized raw coal Collection tank support column 10, pulsating power take-off 11, belt 12, small-size raw coal collection tank 13, large-size raw coal collection tank 14, hinged legs 15, wherein the debris screen 1 and slideway groove 4 are arranged on the support frame 2 Above, the sundry screen 1 is provided with holes for the separation and falling of raw coal; the slideway groove 4 is set directly under the sundry screen 1, and the guiding and dropping chute 5 is set at the end of the slideway groove 4, so that the raw coal falls to the receiving hopper 6 , In addition, the receiving hopper 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com