Belt longitudinal tearing protection device of belt machine, comprehensive protection device and system

A comprehensive protection device, longitudinal tearing technology, applied in the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problem of not being able to detect belt tearing in time, affecting the normal operation of the belt conveyor, and increasing the degree of belt tearing and other problems, to achieve the effect of real-time automatic monitoring, convenient installation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

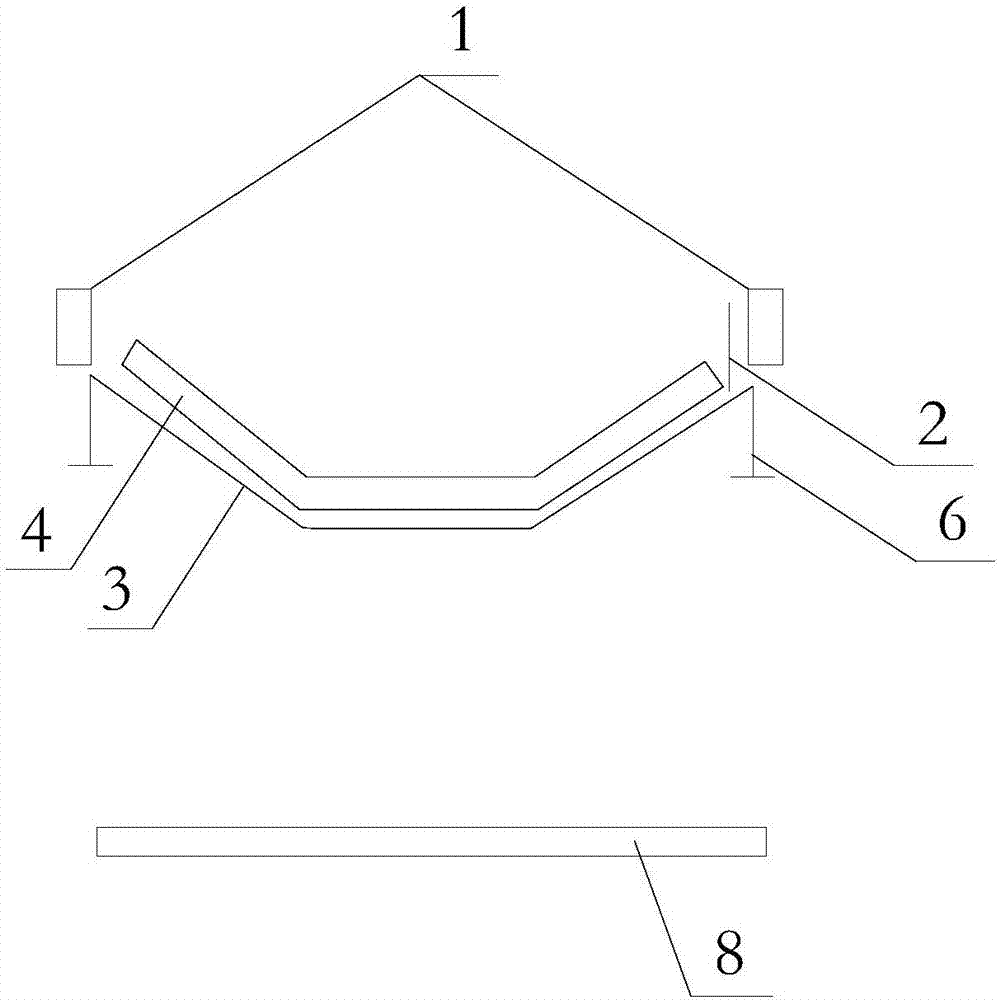

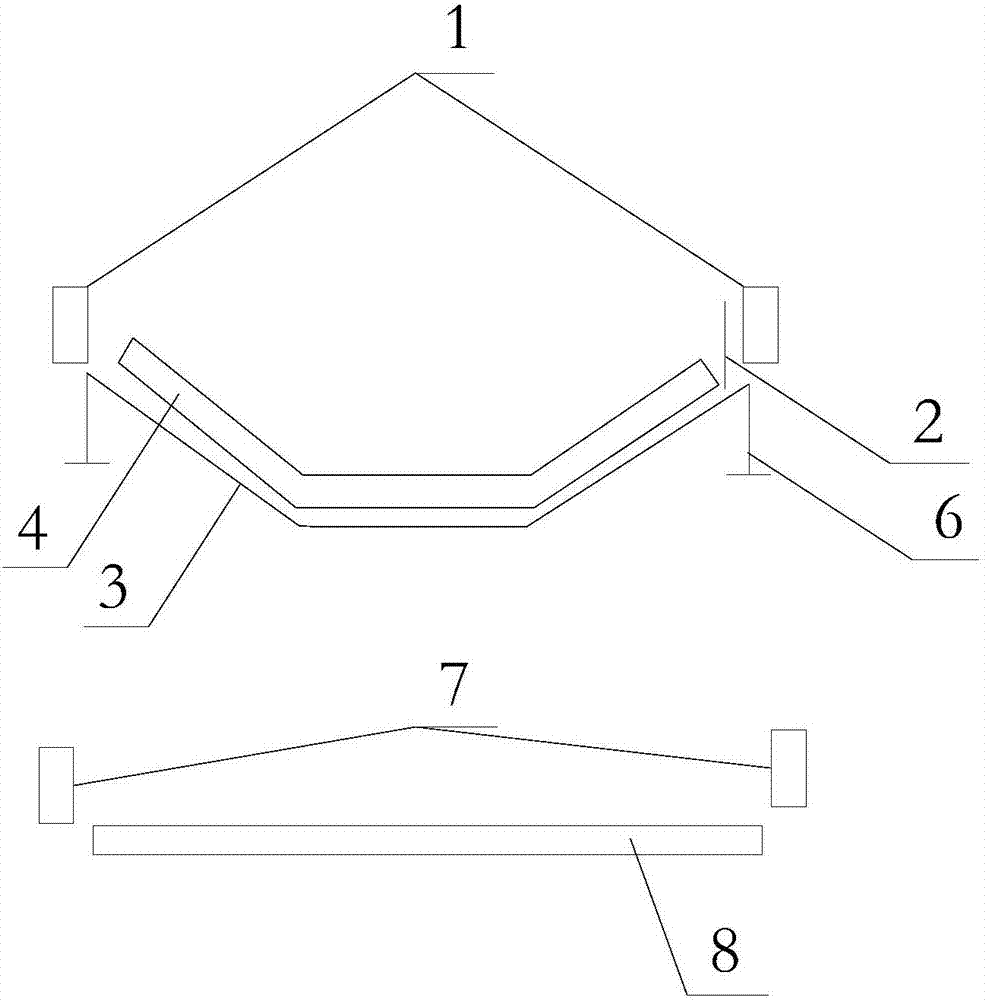

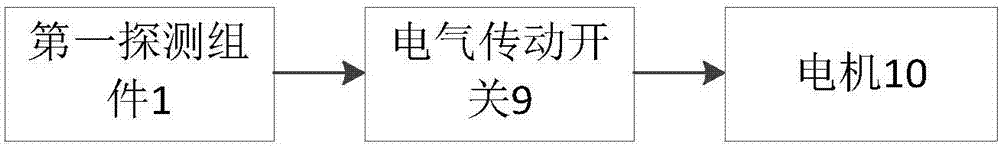

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0041]It should be noted that, in the present invention, the belt of the belt conveyor is annular and closed, and the belt of the belt conveyor moves circularly. The upper belt 4 and the lower belt 8 in the present invention refer to the upper and lower layers of the belt conveyor at a certain moment. Since the belt is in circular motion, when the belt is torn, it may be that the belt on the upper layer is torn, or the belt on the lower layer may be torn, but there is always a moment when the tear will move to the upper layer of the belt conveyor And be detected, so the upper layer belt tear mentioned in the present invention is not only to detect whether the belt on the upper layer is torn, it is also possible that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com