Elastic ball stabilizer

A technology of centralizer and ball, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve problems such as difficulty in running casing, and achieve the effect of simple structure, scientific design and reduced frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

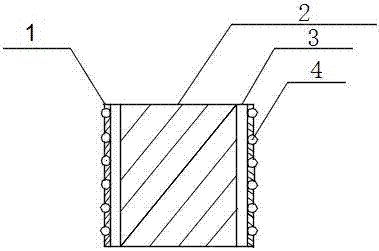

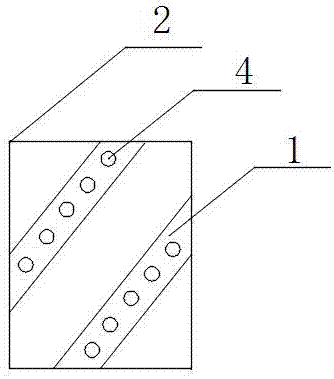

[0032] The present invention will be further described below in conjunction with accompanying drawing.

[0033] In each fixing rib 1 of the present invention, a leaf spring 3 with a plurality of middle holes is arranged at a position close to the outer wall of the main body 2 of the centralizer.

[0034] Each ball 4 of the present invention corresponds to the middle hole of a leaf spring.

[0035] In the present invention, the hole surface of each middle hole is ground into a concave spherical surface matching with the ball 4 .

[0036] The leaf spring 3 of the present invention provides supporting force to each ball 4 .

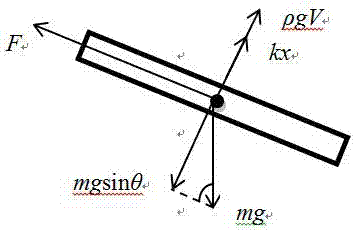

[0037] The elastic coefficient of the leaf spring 3 used in the present invention is set according to the difference of the well inclination angle.

[0038] The calculation method of the elastic coefficient of leaf spring 3 among the present invention is mgsinθ-kx-ρ m gV=0.

[0039] The elastic coefficient set according to the different well inclination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com