Tricycle

A tricycle and main frame technology, applied in vehicle parts, bicycle accessories, axle suspension devices, etc., can solve problems such as large safety hazards and easy rollover, achieve safe driving experience, increase the total grounding area, and drive safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

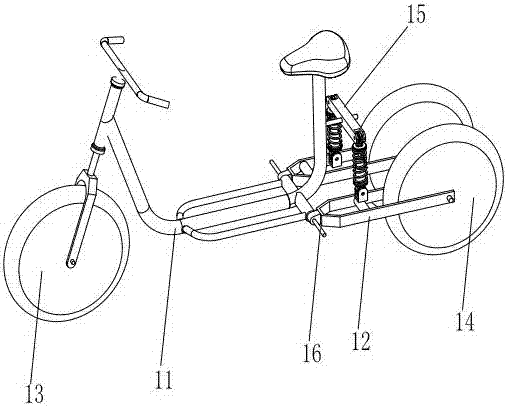

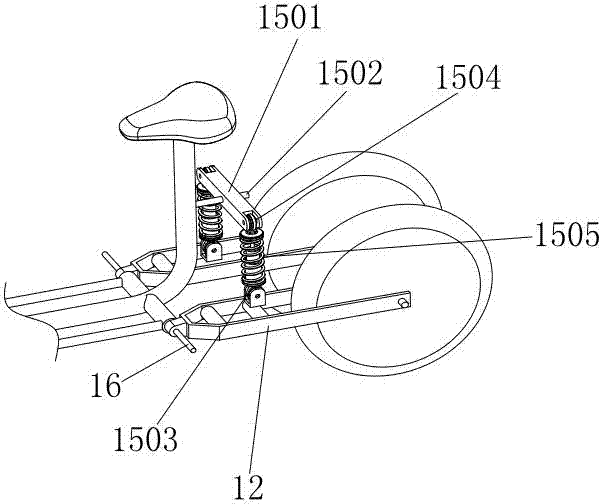

[0032] like Figure 1-2 As shown, the tricycle of the present invention comprises a main frame 11 and two rear rocker arms 12, a front wheel 13 is installed on the main frame 11, a rear wheel 14 is respectively installed on each rear rocker arm 12, and each rear wheel 14 is It is a driving wheel; the main frame 11 is provided with a center shaft 16, the center shaft 16 is parallel to the axial direction of the rear wheels 14, and each rear rocker arm 12 is rotatably sleeved on the center shaft 16;

[0033] A yaw mechanism 15 is installed between the main frame 11 and the two rear rocker arms 12. When the tricycle turned, the yaw mechanism 15 made the two rear rocker arms 12 yaw relative to the main frame 11, and one of the rear rocker arms 12 moves upward relative to the main frame 11 around the central axis 16, and the other rear rocker arm 12 moves downward relative to the main frame 11 around the central axis 16;

[0034] Wherein, the yaw mechanism 15 includes a yaw rod 15...

Embodiment 2

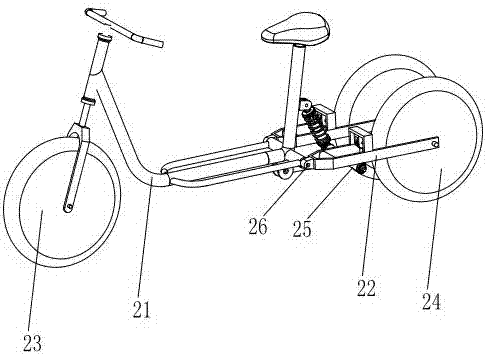

[0040] like Figure 3-5 As shown, the tricycle of the present invention comprises a main frame 21 and two rear rocker arms 22, a front wheel 23 is installed on the main frame 21, and a rear wheel 24 is respectively installed on each rear rocker arm 22, and each rear wheel 24 is It is a driving wheel; the main frame 21 is provided with a center shaft 26, the center shaft 26 is parallel to the axial direction of the rear wheels 24, and each rear rocker arm 22 is rotatably sleeved on the center shaft 26;

[0041] A yaw mechanism 25 is installed between the main frame 21 and the two rear rocker arms 22. When the tricycle turned, the yaw mechanism 25 made the two rear rocker arms 22 yaw relative to the main frame 21, and one of the rear rocker arms 22 moves upwards around the central axis 26 relative to the main frame 21, and the other rear rocker arm 22 moves downwards around the central axis 26 relative to the main frame 21.

[0042] Wherein, the yaw mechanism 25 includes a yaw ...

Embodiment 3

[0048] like Figure 6-7 As shown, the tricycle of the present invention comprises a main frame 31 and two rear rocker arms 32, a front wheel 33 is installed on the main frame 31, and a rear wheel 34 is respectively installed on each rear rocker arm 32, and each rear wheel 34 is It is a driving wheel; the main frame 21 is provided with a center shaft 36, the center shaft 36 is parallel to the axial direction of the rear wheels 34, and each rear rocker arm 32 is rotatably sleeved on the center shaft 36;

[0049] A yaw mechanism 35 is installed between the main frame 31 and the two rear rocker arms 32. When the tricycle turned, the yaw mechanism 35 made the two rear rocker arms 32 yaw relative to the main frame 31, and one of the rear rocker arms 32 moves upward relative to the main frame 31 around the central axis 36, and the other rear rocker arm 32 moves downward relative to the main frame 31 around the central axis 36.

[0050] Wherein, the yaw mechanism 35 includes a yaw ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com