Novel energy-saving corrugated roller

A corrugated roller, a new type of technology, applied in the direction of machining/deformation, can solve the problems of aggravating the wear process, reducing production efficiency, easy damage, etc., and achieve the effect of speeding up installation, improving production efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

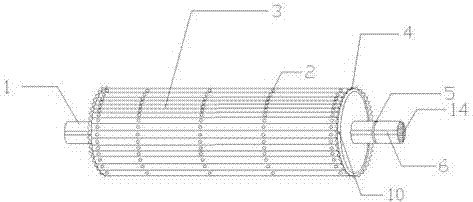

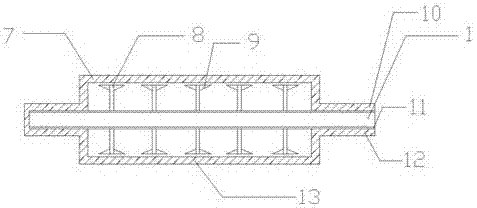

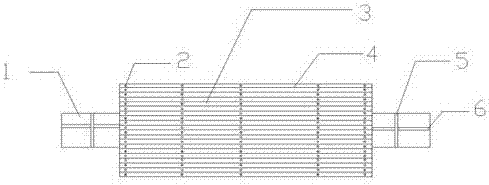

[0022] Example: such as Figure 1-5 As shown, the present invention provides a new type of energy-saving corrugating roller, which includes an outer roller body 3, and the outer roller body 3 is provided with sawtooth 4, which is used for producing corrugated paper and rolling and forming corrugated paper. There are five rows of exhaust holes 2, which are mainly used to dissipate the heat inside the outer roller body 3 to the surface of the corrugated roller, because the corrugated paper needs to be heated during the production of corrugated paper, which is convenient for production. One side of the outer roller body 3 is provided with an inner roller body 1, and the inner roller body 1 is mainly used for fixing. It is mainly used for installing corrugated rollers, which is convenient for installation and will not cause installation errors. An anti-slip ring 5 is provided on one side of the fool-proof gap 6, which is not easy to slip during installation and plays an anti-skid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com