Intelligent assembler with K-shaped accessory chain

An assembly machine and assembly mechanism technology, applied in the direction of metal chains, etc., can solve the problems of low assembly efficiency, high labor intensity of workers, unstable chain outer frame and row spacing, etc., to achieve fast chain assembly speed, saving enterprise labor costs, Good quality chain assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

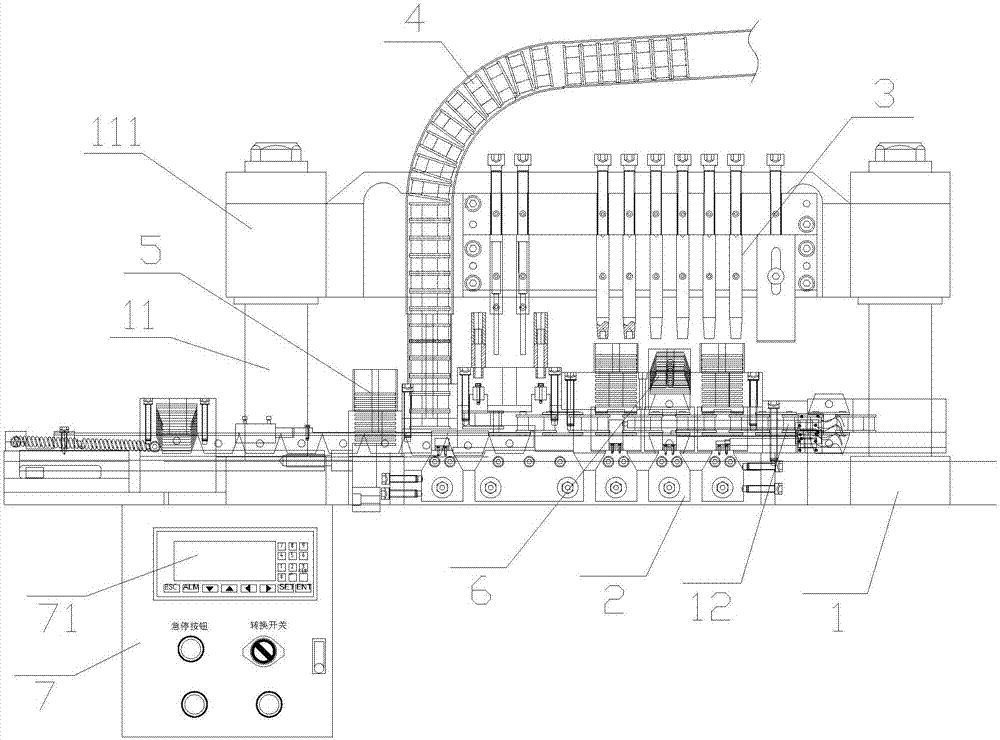

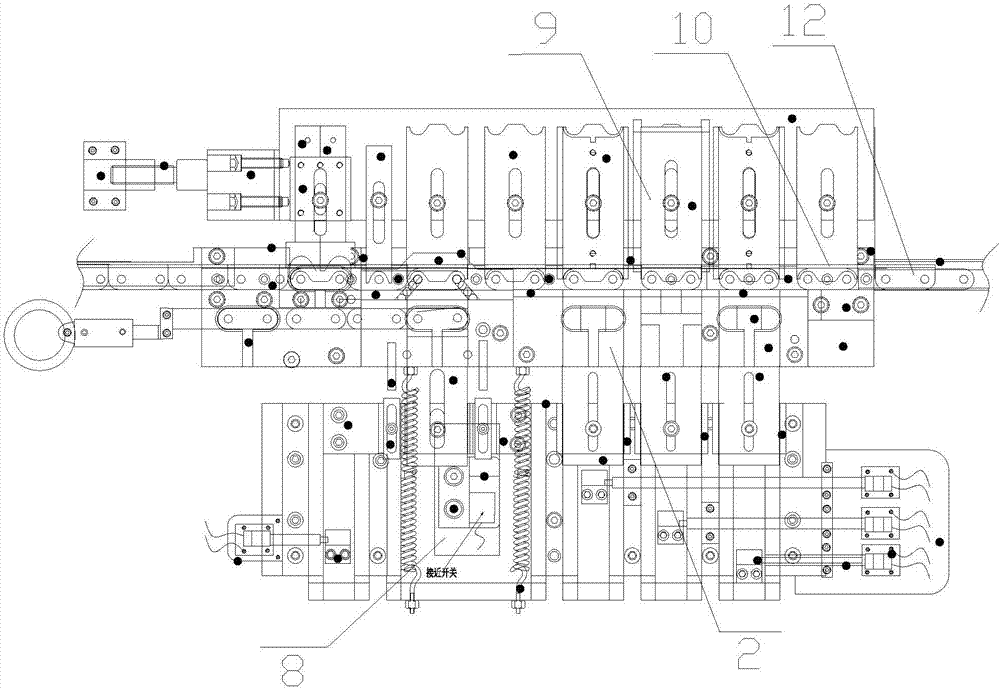

[0023] Such as Figure 1 to Figure 5 As shown, the present invention discloses an intelligent assembly machine with a K-type attachment chain. The intelligent assembly machine includes a machine tool workbench 1 and a PLC automatic control terminal. The locating clip 10, the locating clip 10 positions the single section and the outer chain sheet 121, so that the pin shaft 123 is conveniently packed into the single section and the outer chain sheet 121. One side of the positioning clip 10 is provided with an automatic assembly mold 2 , and the outside of the positioning clip 10 is provided with a chain mold lateral feeding mechanism 9 that cooperates with the positioning clip 10 . The outside of the automatic assembly mold 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com