Inner heating floor

An internal heating and flooring technology, applied in the field of flooring, can solve problems such as high cost of use, cumbersome operations, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further description will be made below in conjunction with drawings and embodiments.

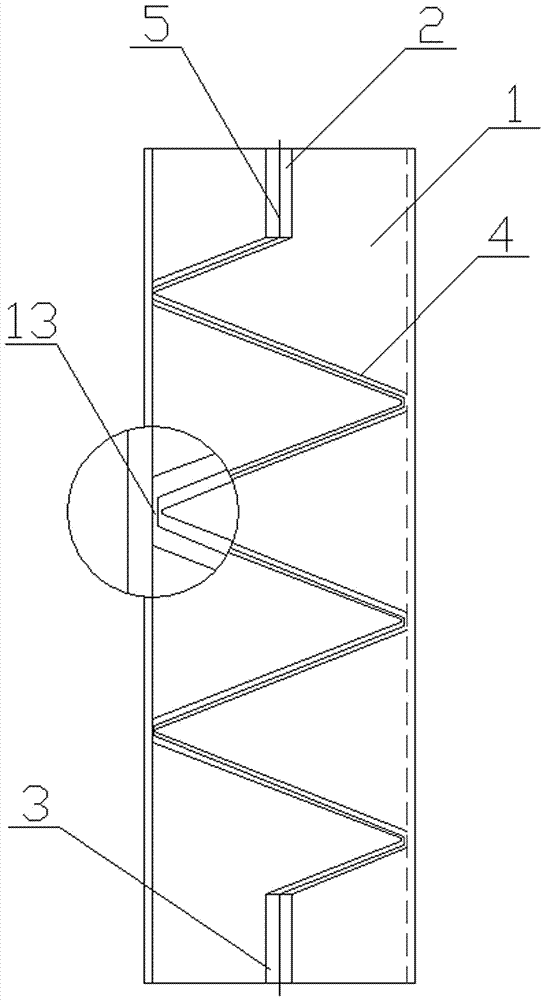

[0013] figure 1 As shown: an internal heating floor includes a floor 1 and a heating cable 5. Front and rear docking notches 2 and 3 are provided in the middle of the bottom of the front and rear ends of the floor 1 respectively. Two oblique holes 4 connected end to end, the first oblique hole is connected to the front docking notch 2, the last oblique hole is connected to the rear docking notch 3, and the heating cable 5 is connected to the rear from the front docking notch 2 through multiple oblique holes 4 Butt notch 3.

[0014] A detour space 13 for accommodating the heating cable 5 is reamed at the junction of the oblique holes on the tenon side and the tenon side of the floor 1, so as to avoid occupying the space between the tenon and the tenon and obstructing the jointing of the tenon and the tenon.

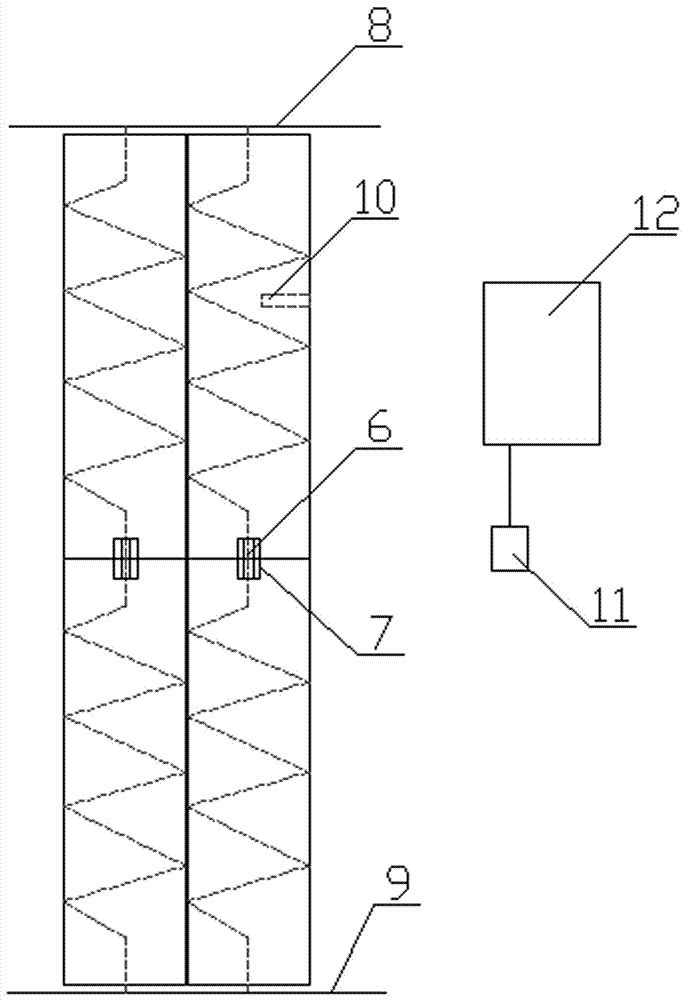

[0015] figure 2 Shown: When the floor is laid, the front and rear docking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com