Automatic CNC loading and unloading device as well as loading and unloading method

A technology for automatic loading and unloading of materials, applied in metal processing and other directions, can solve problems such as affecting the output of CNC processing units, uncontrolled push-pull quality, and inability to process, so as to solve the problem of human resources tension, reduce workpiece push-pull bumps, The effect of reducing the beat of the action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

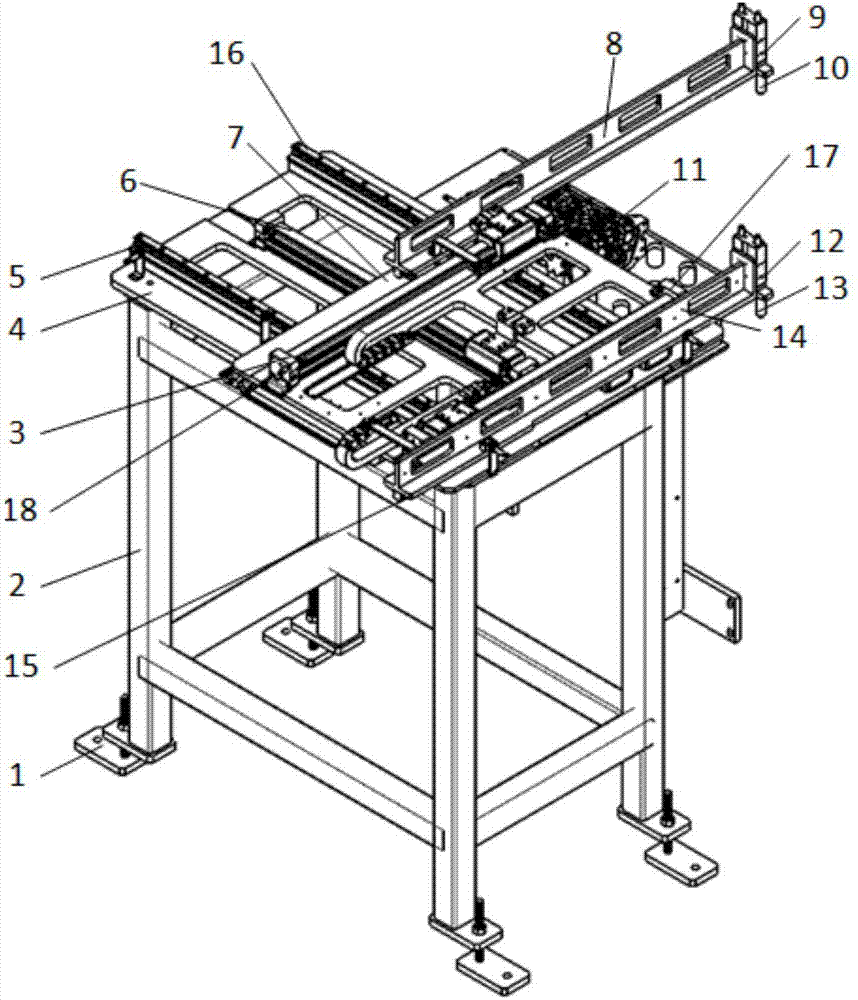

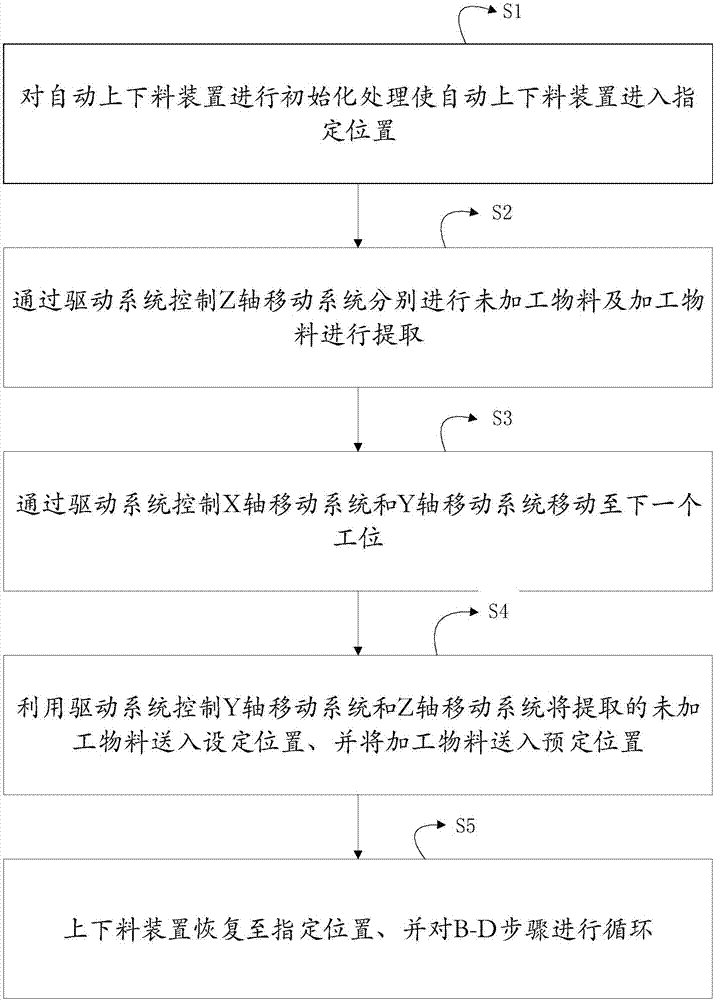

[0029] The CNC feeding machine among the present invention is a cylinder head CNC processing machine, such as figure 1 It can be seen that the present invention consists of a base, an X-axis moving system, a Y-axis moving system, a Z-axis moving system, and a drive system, and completes the cyclic actions of the equipment in the shortest time through logical overlapping of motion actions.

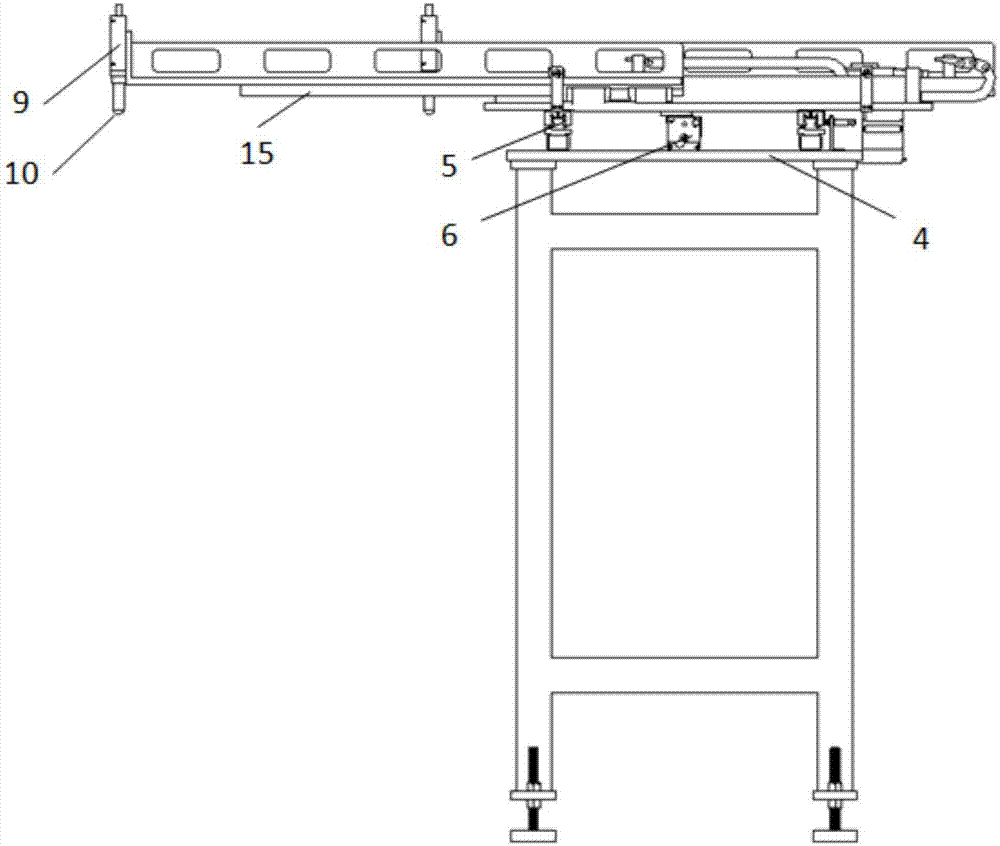

[0030] Such as figure 1 and figure 2 It can be seen that the X-axis moving system, the Y-axis moving system, and the Z-axis moving system in the present invention are all driven by a drive system, and the drive system includes a PLC controller, several driving parts, the first cylinder 6, the second cylinder 3, and the third cylinder 17. The fourth cylinder 9 and the fifth cylinder 12, several of the driving parts are respectively installed on the first cylinder 6, the second cylinder 3, the third cylinder 17, the fourth cylinder 9 and the fifth cylinder 12, the PLC control The output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com