Automatic baking and shaping device for thin crispy biscuits

An automatic and crispy technology, which is applied in baking, baking workshops, food science, etc., can solve problems such as uneven rotation speed, food contamination, troublesome carrying, etc., to achieve convenient and fast molding, controllable rotation speed, and reduce labor intensity Effect

Active Publication Date: 2017-11-10

安徽众侑食品有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Food processing is the operation of using food raw materials to process them into edible items. For thin and crispy biscuits, it is usually achieved by frying or baking. For frying, the heat is relatively large and the taste is relatively good. Greasy, not easy to promote

[0003] Traditionally, for the production of crisp biscuits, the traditional production tools are continuously rotated manually to effectively bake each side of the crisp biscuits. However, manual rotation is not only relatively strong, but also the rotation speed is uneven, resulting in baking The baking degree of the baked surface is not good, which affects the taste. In order to facilitate the sale, when the crispy biscuits are formed, they need to be shaped. Usually, each crispy biscuit is manually rotated on a trapezoidal rotating cylinder for a circle. To get the desired shape, due to the manual molding operation, the hands are always in contact with the food, which may contaminate the food and affect the health of the eater. Moreover, the traditional baking and molding tools are separated and it is troublesome to carry. Therefore, in order to solve these problems, It is necessary to design a new type of crisp biscuit production equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

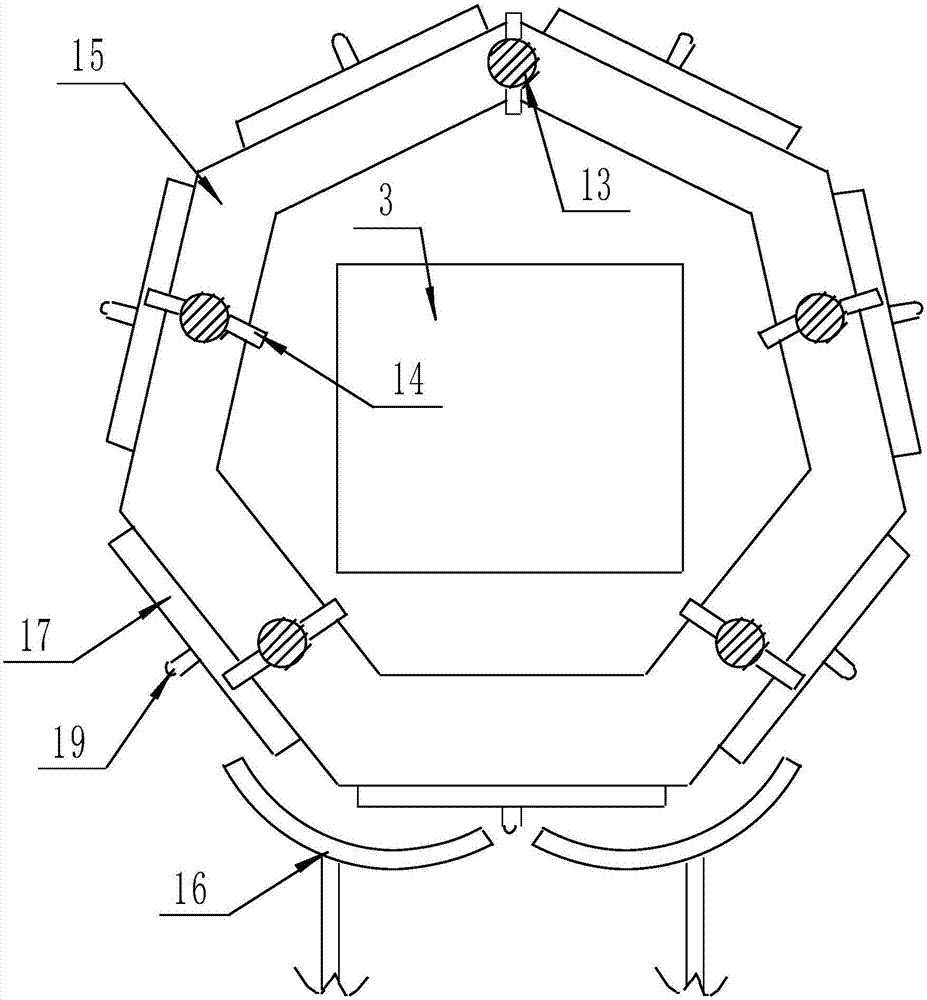

[0026] Embodiment 2: The cooperation between the electric control heat insulation trolley 13 and the ring slide rail 12 can be replaced by a rotating motor, which can also achieve the effect of rotation. For this device, the combination of the rotating motor and the gear meshing is required to realize the hollow Rotate, other structures are identical with embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

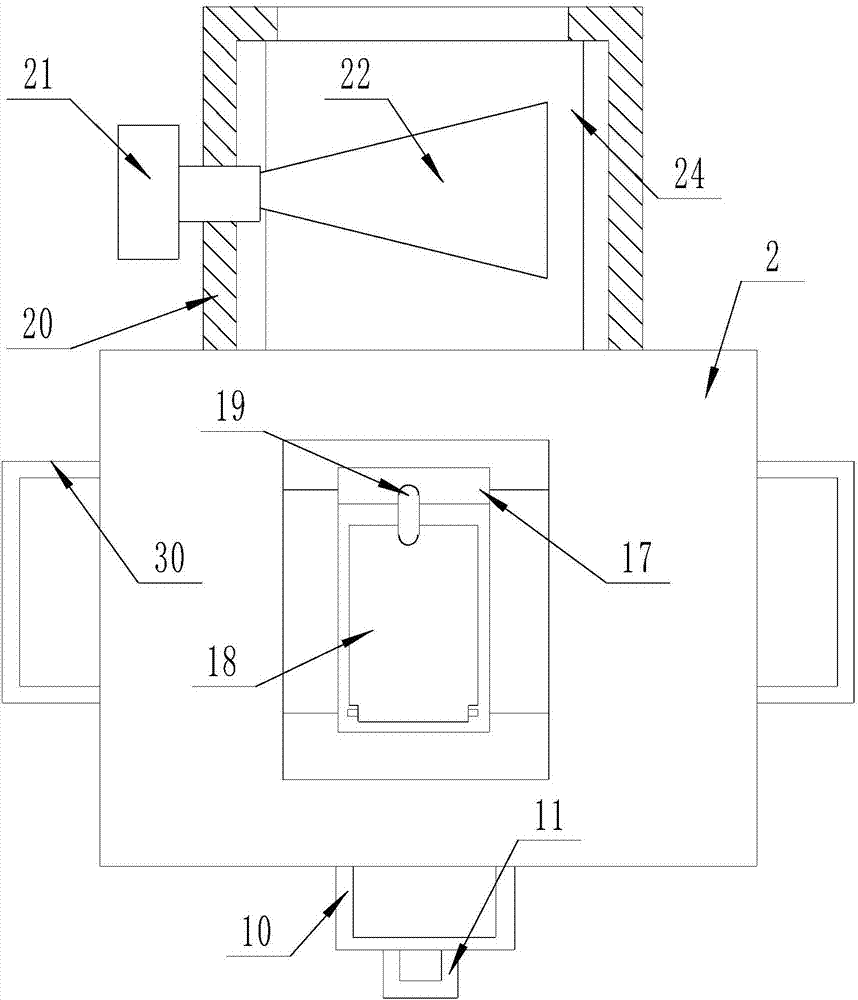

The invention discloses an automatic baking and shaping device for thin crispy biscuits. The automatic baking and shaping device for the thin crispy biscuits comprises a bar-shaped bearing base; a bar-shaped bearing box is arranged on an upper surface of the bar-shaped bearing base in fixedly connection; a baking mechanism is arranged at a center position in the bar-shaped bearing box; an automatic rotary bearing mechanism is arranged outside the baking mechanism in the bar-shaped bearing box; a shaping mechanism is arranged on a right side surface of the bar-shaped bearing box in fixed connection; and a fixing mechanism is arranged on a lower surface of the bar-shaped bearing base. The automatic baking and shaping device for the thin crispy biscuits has the following beneficial effects: the automatic baking and shaping device for the thin crispy biscuits is relatively convenient in operation, relatively uniform in baking effect, controllable in rotation speed, capable of reducing labor intensity, convenient and quick in shaping process, improved in production efficiency, relatively few in hand contact, and assured of food safety.

Description

technical field [0001] The invention relates to the field of food processing, in particular to a device for automatically baking and forming thin and crispy biscuit. Background technique [0002] Food processing is the operation of using the raw materials of food to make edible items. For thin and crispy biscuits, it is usually realized by frying or baking. For frying, the heat is relatively large and the taste is relatively high. Greasy and not easy to promote. [0003] Traditionally, for the production of crispy biscuits, the traditional production tool is to continuously rotate manually to effectively bake each side of the crispy biscuits. The baking degree of the baked noodles is not good, which affects the taste. In order to facilitate the sale, when the crispy biscuits are formed, they need to be shaped. Usually, each crispy biscuits are manually rotated on the trapezoidal rotating cylinder for one week. To get the desired shape, due to the manual molding operation, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A21B7/00

CPCA21B7/00

Inventor 赵淑娟

Owner 安徽众侑食品有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com