Angle valve and steel cylinder

An angle valve and valve core technology, applied in the field of steel cylinders using the angle valve, can solve the problem of easy cracking of the angle valve, and achieve the effect of improving the anti-cracking ability, simple structure and good structure concealment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

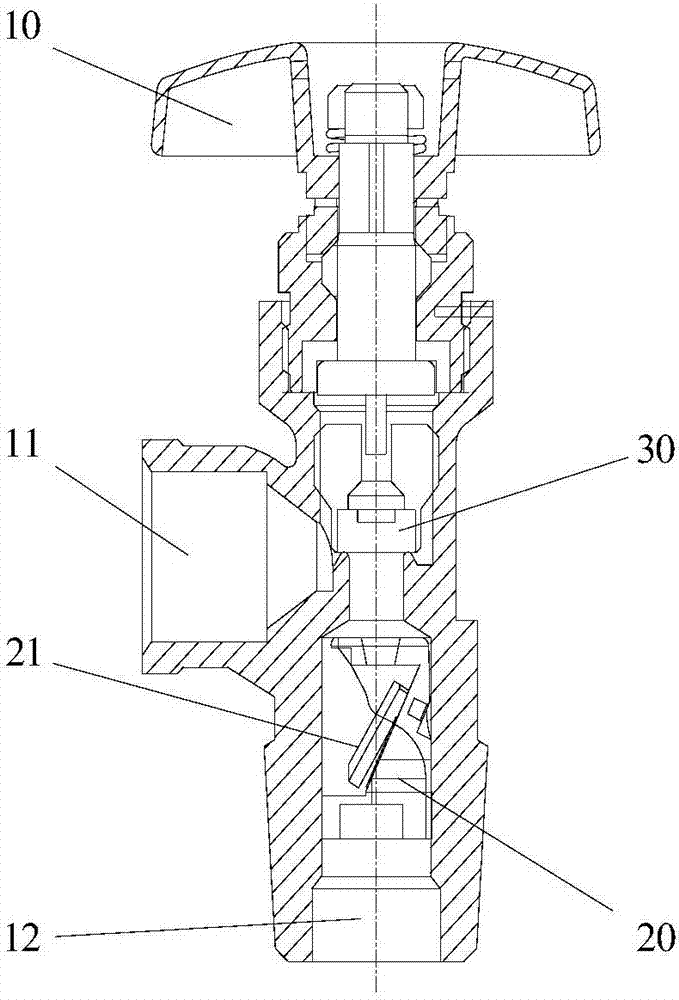

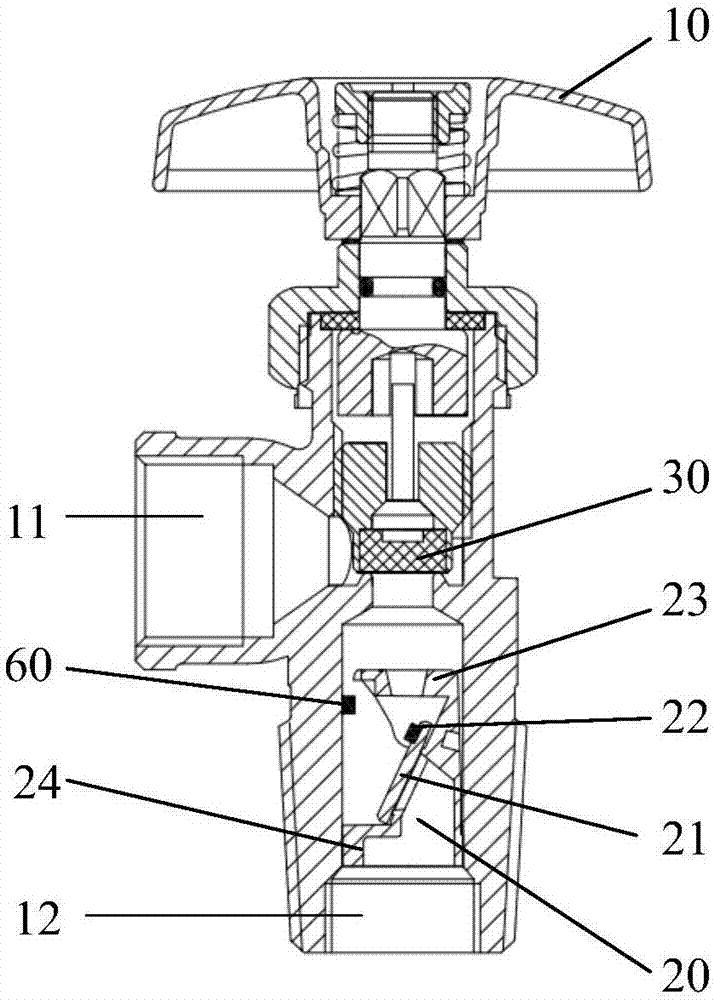

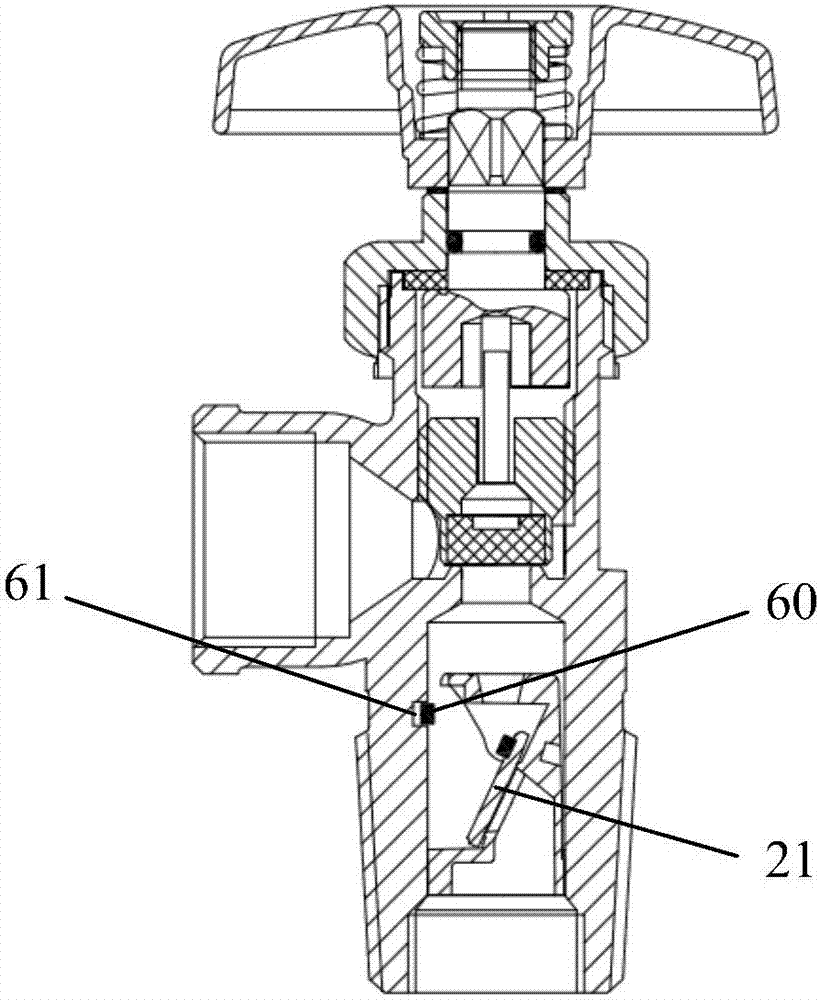

[0052] Such as figure 2 As shown, the angle valve of the present invention includes an angle valve body 10, an angle valve spool 30 installed in the angle valve body 10, an anti-filling valve core 20 installed in the air inlet cavity of the angle valve body, a magnet A22 and Magnet B60.

[0053] The angle valve body 10 includes an air inlet 12 and an air outlet 11 arranged transversely and intersecting each other. The axis of the air outlet 11 intersects the axis of the air inlet 12 and defines a plane as the central plane of the angle valve.

[0054] The anti-filling spool 20 includes an upper valve body 23 and a lower valve body 24 that cooperate with each other, a sealing plate 21 that closes the venting path port of the spool, and a sealing plane that sets the venting path port and cooperates with the sealing surface of the sealing plate 21 (can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com