Method for mounting steel-structure module in place

A steel structure and steel column technology, applied in the direction of basic structure engineering, building structure, construction, etc., can solve the problems of increasing the risk of damage to bolts, difficult control of welding quality, and difficulty in installation, so as to avoid reaming and The effect of welding process, guaranteeing strength and guaranteeing construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

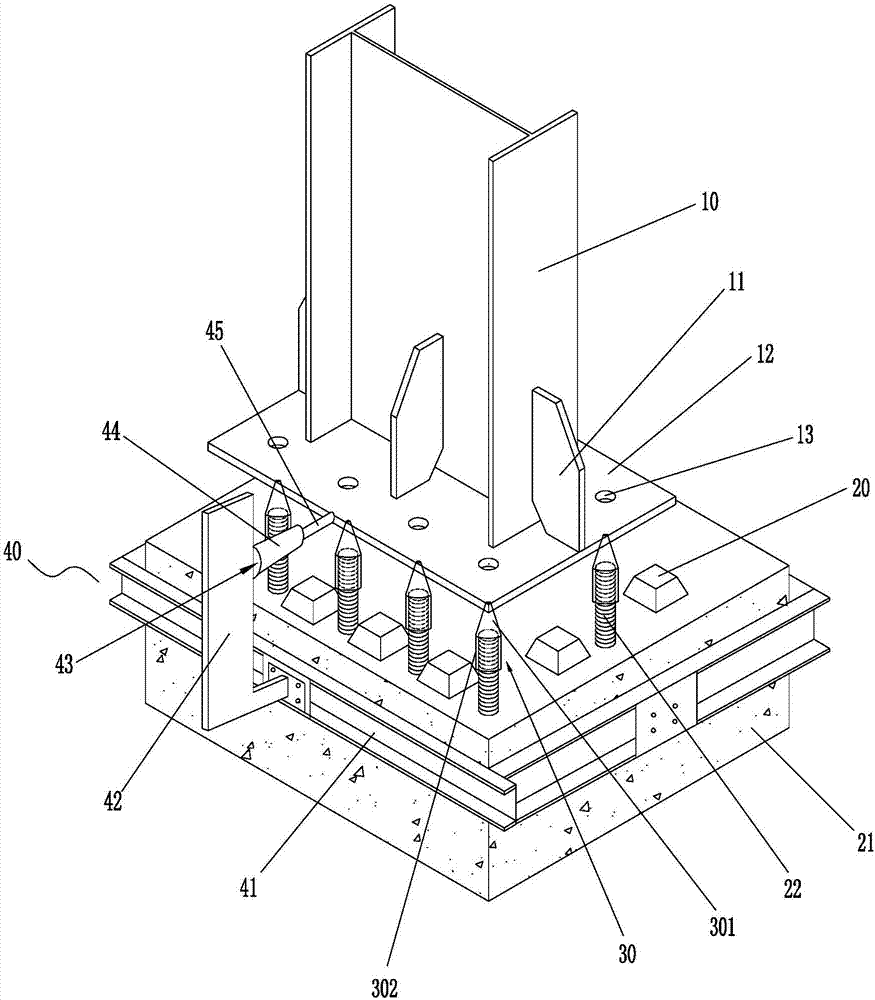

[0022] A method for installing a steel structure module of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0023] Such as figure 1 As shown, in this specific embodiment, a method for installing a steel structure module in the present invention includes the following steps:

[0024] (1) A number of anchor bolts 22 are installed in place;

[0025] (2) Concrete foundation 21 is poured to ensure that the threaded section of anchor bolt 22 exposes the top surface of concrete foundation 21;

[0026] (3) On the top surface of the concrete foundation 21, some steel column base slurry blocks 20 are set, and each steel column base slurry block 20 is a trapezoidal platform structure with a small top and a large bottom;

[0027] (4) Make guiding device 30, this guiding device 30 comprises hollow conical section 301 and hollow cylindrical section 302, the height of hollow conical section 301 is slig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com