Prestressed pipeline segment suitable for detecting and monitoring grouting quality in pipeline

A prestressed pipeline and internal pressure technology, which is applied to bridge parts, bridge materials, bridges, etc., can solve the problems of easy failure, high cost, labor and time-consuming strain gauges, etc., and achieve mechanized operation, high feasibility, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

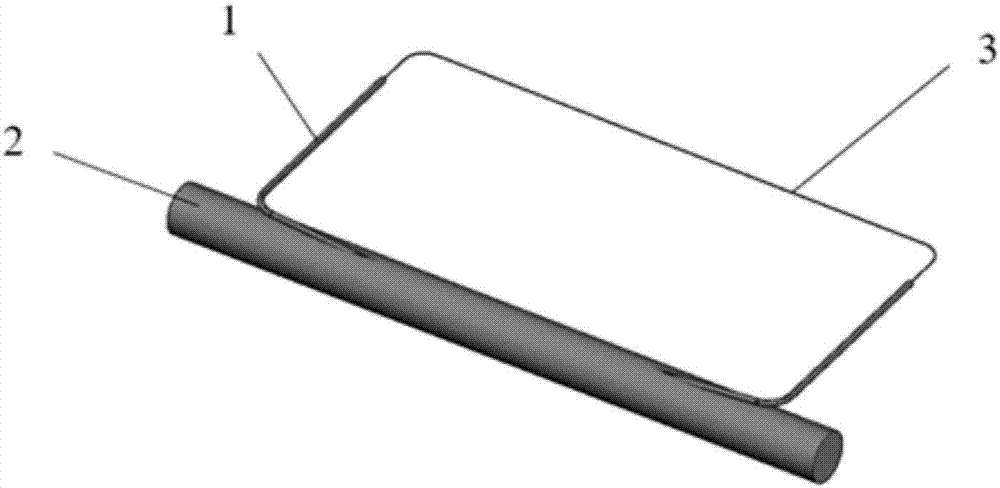

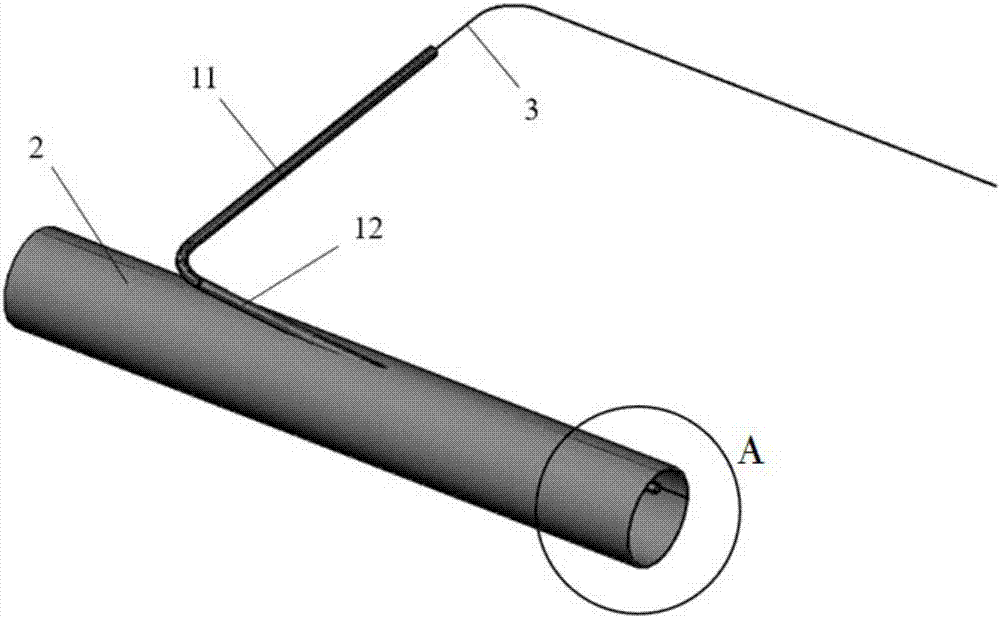

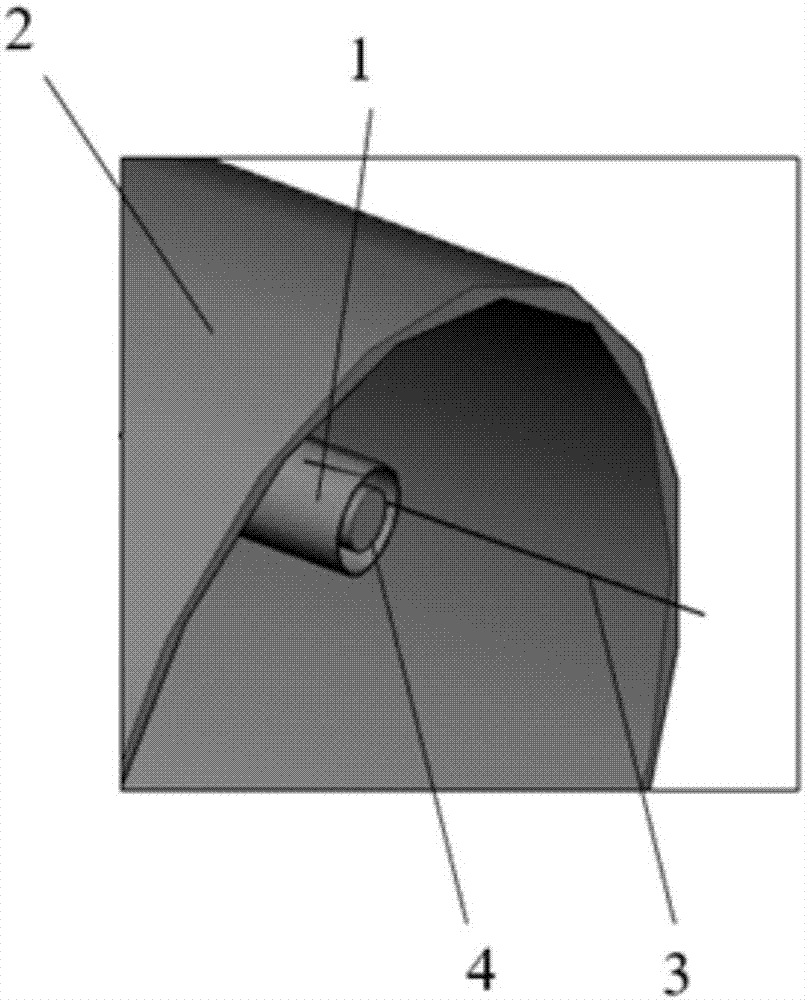

[0040] A prestressed pipe segment suitable for testing and monitoring the quality of grouting inside the pipe, structural reference Figure 1-Figure 6 As shown, it includes standard prestressed pipe 2, reserved transparent pipe 1, pinhole probe 4 and traction rope 3, wherein the standard prestressed pipe 2 is used for the passage of prestressed steel beams, and is placed in the external concrete member 5 during use The reserved transparent pipeline 1 is composed of a connected curved section 11 and a straight section 12, the curved section 11 is located inside the standard prestressed pipeline 2, and the straight section 12 is located outside the standard prestressed pipeline 2; the pinhole probe 4 is located in the reserved transparent pipeline 1 Inside, it is used to detect and monitor the grouting quality in the standard prestressed pipeline 2; the traction rope 3 is used to pull the pinhole probe 4 to pass through the reserved transparent pipeline 1, and the traction rope 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com