Film pasting device for 3D glass with two opposite edges as curved edges and film pasting method

A film sticking device and glass technology, which is applied in packaging and other directions, can solve the problems of not being suitable for 3D glass film sticking, and achieve the effects of good film sticking effect, easy parts, and simplified device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

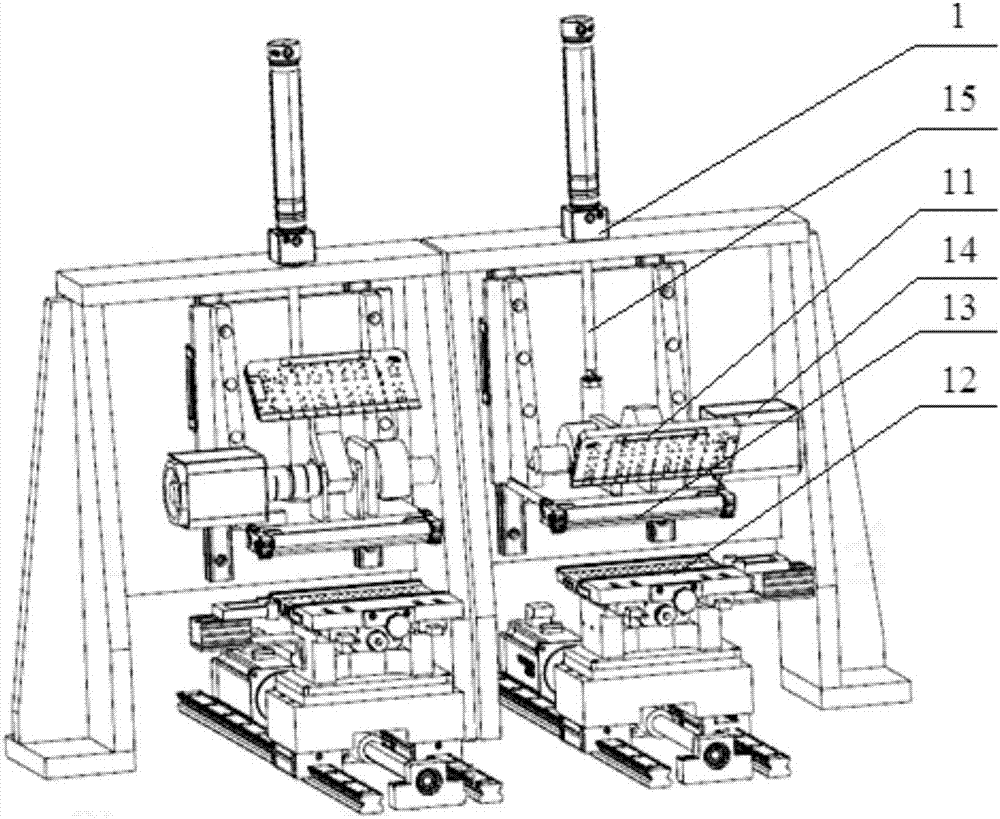

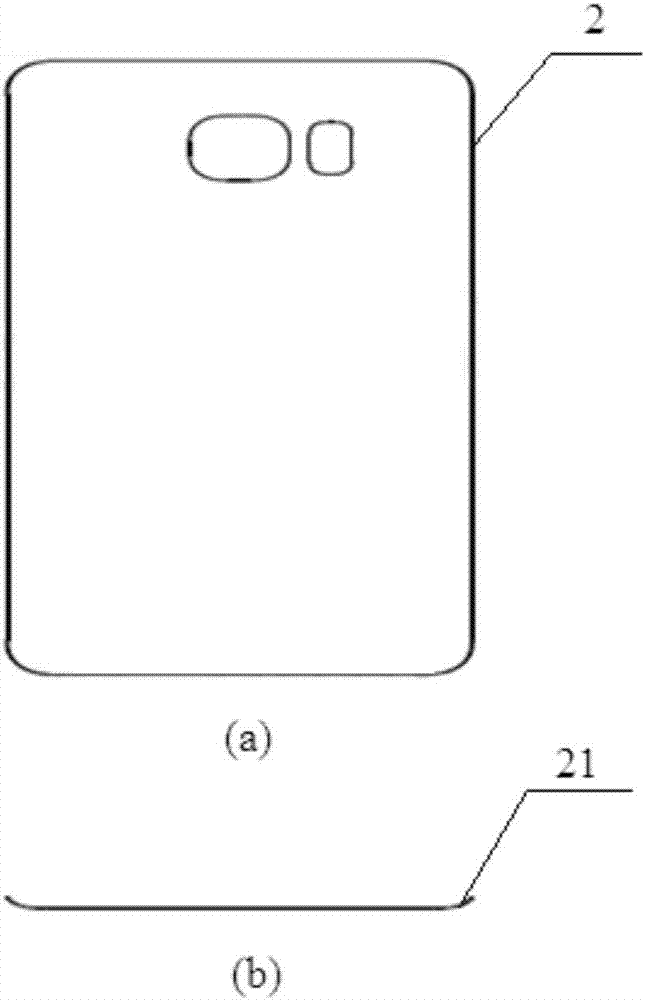

[0039] Fig. 1 is the structure schematic diagram of the film sticking device in the present invention, it can be seen from the figure that the film sticking device 1 comprises an upper base 11 for fixing the film film 3, a lower base 12 for fixing the 3D glass 2, and a roller structure 13 for The rotary cylinder 14 for rotating the upper base, and the lifting cylinder 15 for the upper base, the rotary cylinder and the roller structure to move up and down and make the roller structure exert pressure on the glass and film. In the present invention, the rollers, the rotating cylinder and the upper base are all parts installed separately, and they can all be fixed on the support plate driven by the upper and lower cylinders.

[0040] figure 2 with image 3Sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com