Haze removing system with magnetic fluid self-replacing filter element in city pipeline corridor

A magnetic fluid and urban technology, applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of difficult replacement and high cost of filter elements, save floor space, solve high cost of use, and no secondary The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

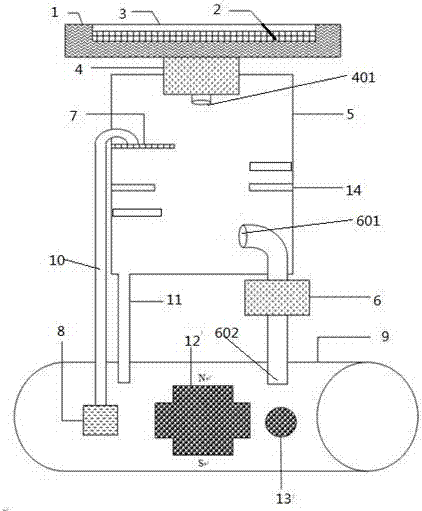

[0020] Such as figure 1 As shown, a self-replacing haze removal system for a magnetic fluid filter element in an urban pipe corridor includes an underground haze removal well 5, a well cover 1, an upper fan 4, a lower fan 6, a water pump 8, a spray device 7 and a power supply unit, and the well cover 1 is equipped with The air intake hole is provided with a well cover 1 on the haze removal well 5, and an upper fan 4 is arranged below the well cover 1. The air inlet of the upper fan 4 is located on the lower surface of the well cover 1, and the gas outlet 401 of the upper fan is located in the haze removal well. The air inlet 601 of 6 is located in the haze removal well, and the air outlet 602 of the lower blower fan 6 is connected to the city rainwater pipeline 9, and the spray device 7 is positioned at the top of the haze removal well, and the water pump 8 is located in the rainwater pipeline 9 and passes through the water delivery pipeline 10 and the spray The device 7 is co...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that the permanent magnet 13 is not included, the rainwater inversion plate 12 is not magnetic, and the rainwater inversion plate 12 is connected with a motor, which drives the rainwater inversion plate 12 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com