High-frequency vibration test bed for axle-end bearing of double-axle and double-rotation railway vehicle

A rail vehicle and double-rotation technology, which is applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as inability to carry out research tests on bearings, and achieve the goal of improving reliability and stress state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

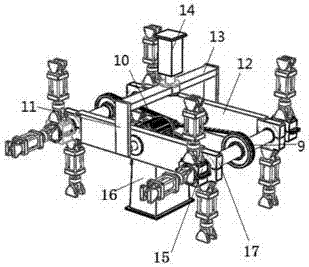

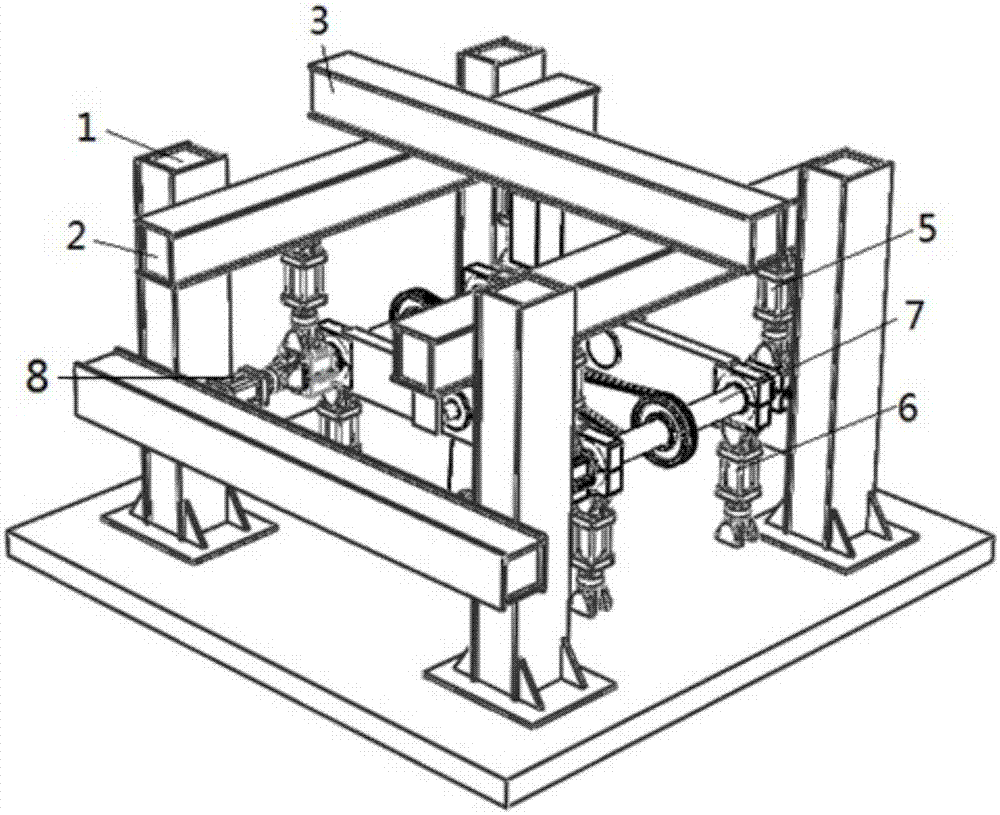

[0009] refer to figure 1 , figure 2 , the framework of the present invention is made of four upright columns 1, the upper beam 3 of the framework, the side beam 4 of the framework, and two longitudinal beams 2. An AC motor 10 is installed on the motor base 16, and the AC motor 10 passes through the pulley 9, the belt and the front and rear two The simulated axles 7 are connected, and the two ends of the simulated axles 7 are equipped with axle-end axle boxes 15, and the left side of the axle-end axle boxes is connected with the transverse actuator 8, and the other end of the transverse actuator 8 is fixed on the side beam 4 of the frame. The upper side of the end axle box is connected with four simulated static load actuators 5, and the other end of the simulated static load actuators 5 is fixed on the frame longitudinal beam 2, and the corresponding wheel set of each simulated wheel axle is equipped with a wheel set simulation shaft Box 17, bearings are housed in the wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com