Control method of side wall concrete crack of urban rail transit underground station body structure

A technology for urban rail transit and underground stations, applied in the field of concrete crack control of the main structure of the main structure of urban rail transit underground stations, can solve problems such as shrinkage cracking, achieve small temperature shrinkage and autogenous shrinkage, avoid leakage, and promote full hydration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

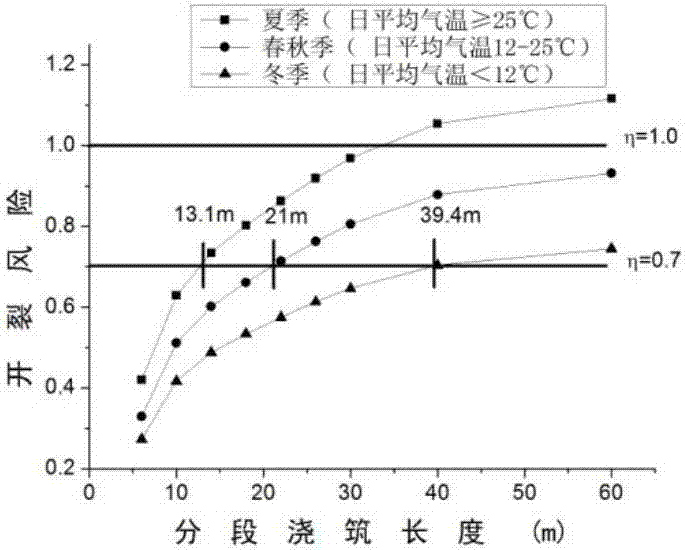

[0056] Such as Figure 4 As shown, the crack control method of the present invention is applied to the main structure of a certain underground station in a northern urban rail transit project with four distinct seasons under a certain general environment. 210m, the design strength grade of concrete is C35P8, and the thickness of the side wall is 0.7m. The waterproof design level of the main structure is first-class, and the requirements for crack resistance and seepage prevention are very high.

[0057] According to the urban rail transit engineering underground station main body structure side wall concrete crack control method provided by the present invention, and in conjunction with the construction unit schedule, the sectioned pouring length and pouring time of the side wall concrete of the whole station are divided as shown in Table 1. The pouring length of the section ranges from 16.3m to 24.5m, and the pouring time is from October 16, 2016 to December 25, 2016, spanni...

Embodiment 2

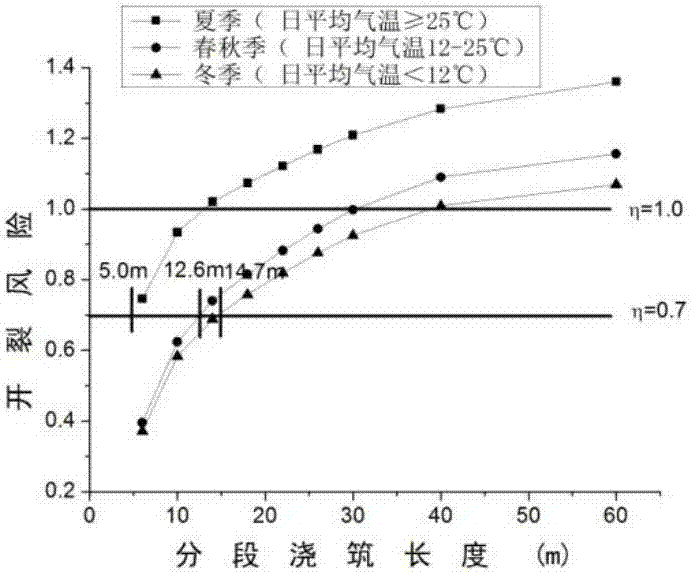

[0067] Such as Figure 4 As shown, the crack control method provided by the present invention is applied to the main structure of an underground station in a certain urban rail transit project in southern Jiangsu with four distinct seasons. The main structure is a 12m island platform standard station with 2 floors underground, and the total length of the station is about 170m. The design strength grade of concrete is C35P8, and the thickness of the side wall is 0.8m. It is constructed by open cut and straight method, and the construction time is summer, autumn and winter. The waterproof design level of the main structure is first-class, and the requirements for crack resistance and seepage prevention are very high.

[0068] According to the urban rail transit engineering underground station main structure side wall concrete crack control method provided by the present invention, the sixteenth running water section of the underground station is selected as the test section for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com