Suction type garbage collecting car

A garbage collection vehicle and garbage technology, applied in the field of garbage collection vehicles, can solve the problems of not having the function of garbage compression, increasing the labor load of operators, and the garbage density of garbage bins is small, so as to achieve high garbage collection efficiency, simple structure, and low noise pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

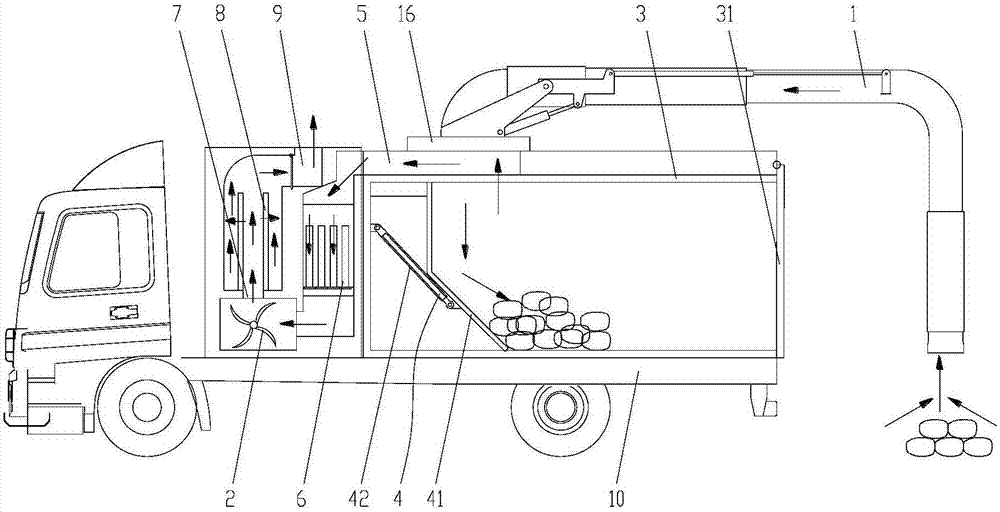

[0033] Such as Figure 1-5 As shown in one of the figures, the suction type garbage collection vehicle of the present invention includes a car chassis 10 on which a suction device 2 and a closed trash can 3 are provided, and a suction port of the suction device 2 It communicates with the inside of the trash box 3 through the air suction channel 5, and the exhaust port of the suction device 2 is in communication with the outside atmosphere through the exhaust duct 7. The top of the trash box 3 is provided with a suction arm 1 that communicates with the inside of the trash box 3. One end of the suction arm 1 is rotatably connected to the trash bin 3 through a slewing support 16. The slewing support 16 is driven to rotate by a hydraulic motor (not shown in the figure) to drive the suction arm 1 to rotate, and the other end of the suction arm 1 is used for pumping Suck garbage.

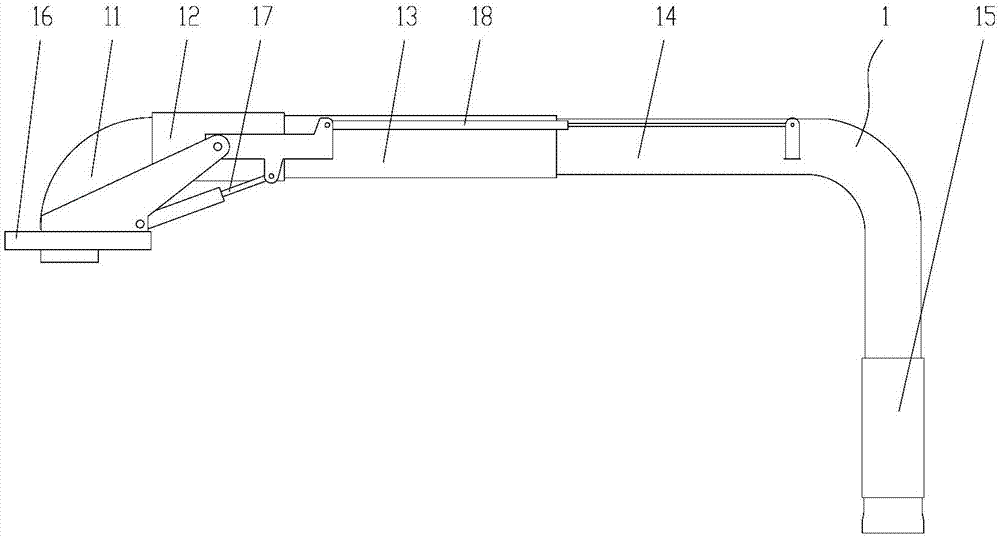

[0034] Such as image 3 As shown, the suction arm 1 includes a base 11, an outer cylinder 13, and an inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com